In materials science, pressureless sintering is a method of compacting and solidifying a powdered material into a solid mass using only heat, without the application of external mechanical pressure. This process relies on the natural tendency of atoms to diffuse across the boundaries of individual particles at elevated temperatures, fusing them together into a single, denser piece.

The fundamental principle of pressureless sintering is that sufficient thermal energy alone can drive atoms to migrate and bond, reducing the material's surface energy. This eliminates the need for complex, high-force equipment, making it an effective technique for specific materials and applications where mechanical stress is undesirable.

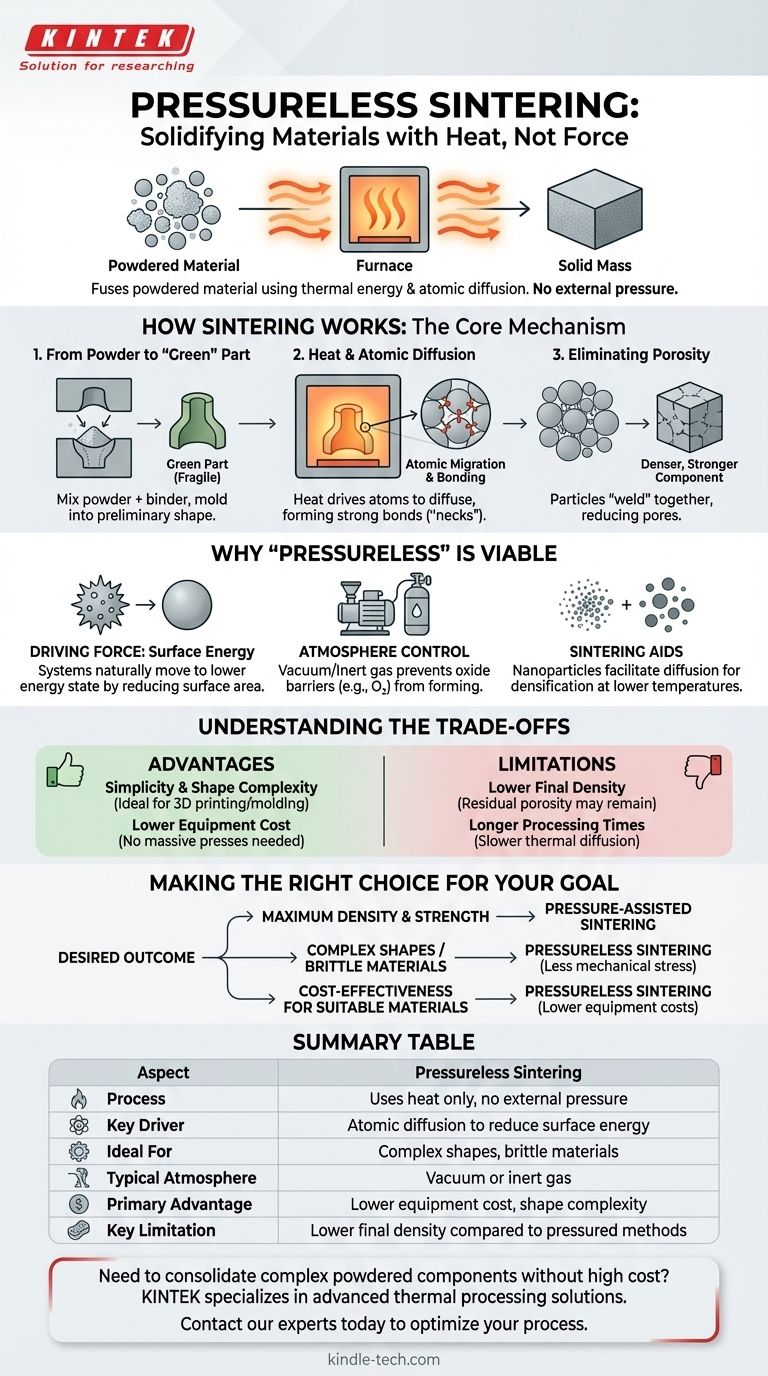

How Sintering Works: The Core Mechanism

Sintering is a thermal treatment that bonds particles together into a coherent, solid structure. While some methods use pressure, the underlying principle of atomic movement is common to all forms of sintering.

From Powder to "Green" Part

The process typically begins by forming a blend of the primary material powder with a temporary bonding agent, such as wax or a polymer. This mixture is molded into the desired preliminary shape, often called a "green part." This initial part is fragile but holds its form.

The Role of Heat and Atomic Diffusion

The green part is then placed in a furnace and heated. In the initial stage, the bonding agent evaporates or burns away, leaving a porous structure of the primary powder.

As the temperature continues to rise—remaining below the material's full melting point—the atoms at the surface of the particles become highly energized. This energy allows them to move and diffuse across the contact points between adjacent particles, forming strong metallic or covalent bonds. These new bonds act as "necks" that grow and pull the particles closer together.

Eliminating Porosity

This atomic migration effectively "welds" the particles together without ever liquefying the bulk material. As the particles fuse and draw closer, the empty spaces, or pores, between them shrink or are eliminated. The result is a denser, stronger final component.

Why "Pressureless" is a Viable Approach

The key to pressureless sintering is creating an environment where atomic diffusion can occur efficiently without the aid of external force.

Driving Force: Surface Energy

A fine powder has an enormous amount of surface area, which corresponds to a high state of surface energy. Systems in nature tend to move toward their lowest energy state. By fusing together and reducing the total surface area, the material achieves a more stable, lower-energy state. Heat simply acts as the catalyst that provides the activation energy for this natural process to occur.

The Importance of Atmosphere Control

Pressureless sintering is often performed in a vacuum or a controlled, inert atmosphere. Removing atmospheric gases like oxygen is critical because these gases can react with the hot material, forming oxide layers on the particle surfaces. These layers act as barriers that prevent atoms from diffusing and bonding, effectively halting the sintering process.

Material Selection and Sintering Aids

This method is particularly effective for materials with high intrinsic atomic mobility, such as certain metal-ceramic composites. To enhance the process for other materials, engineers sometimes introduce nanoparticle sintering aids. These ultra-fine particles mix with the primary powder and facilitate diffusion, allowing for densification at lower temperatures.

Understanding the Trade-offs

Choosing pressureless sintering involves a clear set of advantages and limitations that must be weighed against the project's goals.

Advantage: Simplicity and Shape Complexity

The primary benefit is the ability to create complex shapes. Without the need to apply uniform external pressure, there is less risk of fracturing or distorting intricate designs during consolidation. This makes it ideal for components made via 3D printing or molding.

Advantage: Lower Equipment Cost

Sintering furnaces are expensive, but high-pressure sintering presses are significantly more so. Eliminating the need for massive mechanical presses can substantially reduce capital equipment and operational costs.

Limitation: Lower Final Density

Without external force to physically compact the particles, pressureless sintering may not achieve the same final density as pressure-assisted methods. Some residual porosity might remain, which can impact mechanical properties like strength and hardness.

Limitation: Longer Processing Times

Relying solely on thermal diffusion can be a slower process. Achieving a high-density part may require holding the material at a high temperature for an extended period, which can increase energy consumption and cycle times.

Making the Right Choice for Your Goal

The decision to use pressureless sintering hinges on the desired outcome for the final component.

- If your primary focus is achieving maximum density and strength: Pressure-assisted sintering is often the superior choice as it actively compacts the material, minimizing porosity.

- If your primary focus is producing complex shapes or working with brittle materials: Pressureless sintering offers a significant advantage by avoiding the mechanical stress of external force.

- If your primary focus is cost-effectiveness for suitable materials: Pressureless sintering can reduce equipment and tooling costs by eliminating the need for high-pressure systems.

Ultimately, understanding the interplay between temperature, material properties, and atomic diffusion empowers you to select the most effective consolidation technique for your specific engineering goal.

Summary Table:

| Aspect | Pressureless Sintering |

|---|---|

| Process | Uses heat only, no external pressure |

| Key Driver | Atomic diffusion to reduce surface energy |

| Ideal For | Complex shapes, brittle materials |

| Typical Atmosphere | Vacuum or inert gas |

| Primary Advantage | Lower equipment cost, shape complexity |

| Key Limitation | Lower final density compared to pressured methods |

Need to consolidate complex powdered components without the high cost of pressure equipment?

At KINTEK, we specialize in advanced thermal processing solutions for laboratories. Our expertise in pressureless sintering can help you achieve strong, coherent parts from metal-ceramic composites and other materials, perfect for intricate designs and cost-sensitive projects.

Contact our experts today to discuss how our lab equipment and consumables can optimize your sintering process and meet your specific material science goals.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What temperature is porcelain fired at? A Guide to Precise Dental Firing Cycles

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- What is the function of a porcelain furnace? Precision Firing for Lifelike Dental Restorations

- What is the melting point of tungsten in a vacuum? The Real Limit is Sublimation, Not Melting

- Why are porcelain fired under vacuum? To Eliminate Porosity for Superior Strength & Translucency