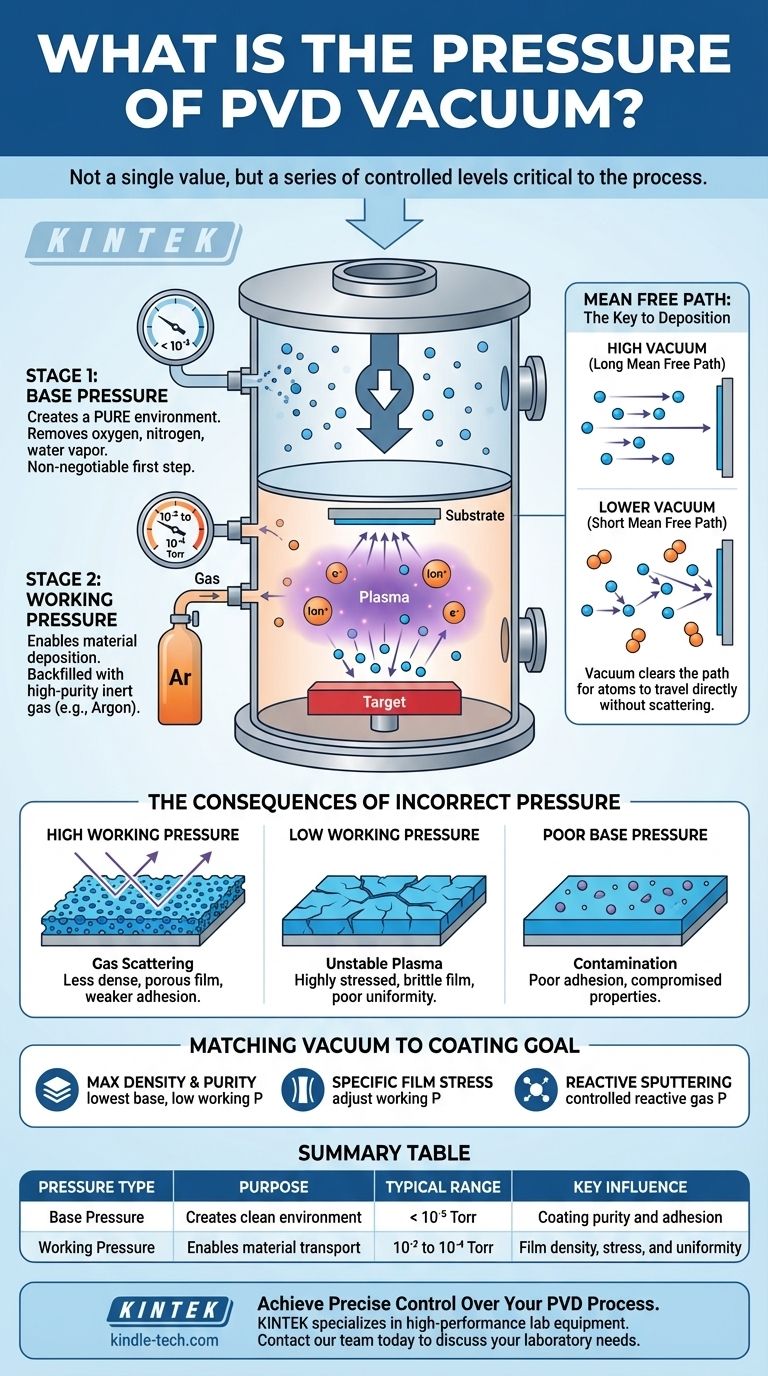

The pressure in a PVD vacuum system is not one single value, but a series of carefully controlled levels critical to the process. The system first achieves a high vacuum base pressure, typically below 10⁻⁵ Torr, to ensure purity. Then, for the coating process itself, an inert gas is introduced to create a working pressure in the range of 10⁻² to 10⁻⁴ Torr.

The quality of a Physical Vapor Deposition (PVD) coating is not determined by a single pressure point, but by the crucial relationship between the base pressure (which ensures a clean environment) and the working pressure (which enables material transport and deposition).

Why Vacuum is the Foundation of PVD

Achieving a deep vacuum is the non-negotiable first step in any high-quality PVD process. This isn't just about removing air; it's about creating a precisely controlled environment for building a thin film, atom by atom.

Eliminating Contamination

The air around us is filled with reactive gases like oxygen, nitrogen, and water vapor. If these molecules are present during deposition, they will become embedded in the coating, creating impurities that compromise its integrity, adhesion, and performance.

A high vacuum physically removes these potential contaminants from the chamber.

Ensuring a Clear Path

The core principle of PVD is moving material from a source (the target) to a destination (the substrate). Vacuum clears the path for these atoms to travel.

This concept is defined by the Mean Free Path: the average distance a particle can travel before colliding with another. In a high vacuum, the mean free path is very long, allowing coating atoms to travel directly to the substrate without being scattered by air molecules.

The Two Critical Pressure Levels

Understanding the distinction between base and working pressure is essential to understanding PVD. Each serves a completely different, yet equally vital, purpose.

Base Pressure: Creating a Pure Environment

Base pressure is the lowest pressure the vacuum system can achieve before the process begins and before any process gas is introduced. It is a direct measure of the chamber's cleanliness.

A lower base pressure (e.g., 10⁻⁷ Torr vs. 10⁻⁵ Torr) indicates that more of the residual contaminant molecules have been removed. This clean slate is critical for ensuring the final coating adheres well and has the desired properties.

Working Pressure: Enabling Material Deposition

Working pressure is the pressure level established after achieving base pressure, by intentionally backfilling the chamber with a small, controlled amount of a high-purity inert gas, most commonly Argon.

This pressure is higher than the base pressure, typically by several orders of magnitude. For sputtering, this Argon is necessary to create the plasma that bombards the target and ejects coating material. The working pressure directly influences the density and stress of the final film.

The Consequences of Incorrect Pressure

Deviating from the optimal pressure range is one of the most common sources of PVD coating failure. The effects are predictable and directly tied to the physics of the process.

What Happens if Working Pressure is Too High?

A working pressure that is too high shortens the mean free path. The sputtered atoms undergo too many collisions with the process gas on their way to the substrate.

This "gas scattering" robs the atoms of their kinetic energy. The result is a film that is less dense, more porous, and has weaker adhesion to the substrate.

What Happens if Working Pressure is Too Low?

If the working pressure is too low, there may not be enough gas atoms to sustain a stable plasma (in sputtering) or to moderate the energy of the depositing particles.

This can lead to a highly stressed, brittle film that may crack or delaminate. It can also cause poor uniformity across the substrate.

The Problem with a Poor Base Pressure

Failing to reach a sufficient base pressure is a critical error. It means contaminants were never fully removed from the chamber.

These contaminants (especially water vapor) will be incorporated into the growing film, leading to poor adhesion, compromised corrosion resistance, and altered optical or electrical properties.

Matching the Vacuum to Your Coating Goal

The ideal pressure settings are a direct function of the desired outcome for your thin film.

- If your primary focus is maximum film density and purity: Prioritize achieving the lowest possible base pressure and operate at the lower end of the stable working pressure range.

- If your primary focus is achieving a specific film stress (compressive vs. tensile): Carefully adjust the working pressure, as it is one of the primary controls for manipulating internal film stress.

- If you are performing reactive sputtering (e.g., TiN): Your most critical parameter becomes the partial pressure of the reactive gas (nitrogen), which must be precisely controlled in addition to the inert gas working pressure.

Ultimately, mastering vacuum pressure is mastering the control, purity, and performance of your PVD process.

Summary Table:

| Pressure Type | Purpose | Typical Range | Key Influence |

|---|---|---|---|

| Base Pressure | Creates a clean, contaminant-free environment | < 10⁻⁵ Torr | Coating purity and adhesion |

| Working Pressure | Enables material transport and deposition | 10⁻² to 10⁻⁴ Torr | Film density, stress, and uniformity |

Achieve precise control over your PVD coating process. The quality of your thin films hinges on mastering vacuum pressure. KINTEK specializes in high-performance lab equipment, including vacuum systems and consumables essential for reliable PVD. Let our experts help you optimize your process for superior results. Contact our team today to discuss your specific laboratory needs.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- How is diamond coating made? A Guide to CVD and PVD Methods

- How do CVD diamonds grow? A Step-by-Step Guide to Lab-Grown Diamond Creation

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods