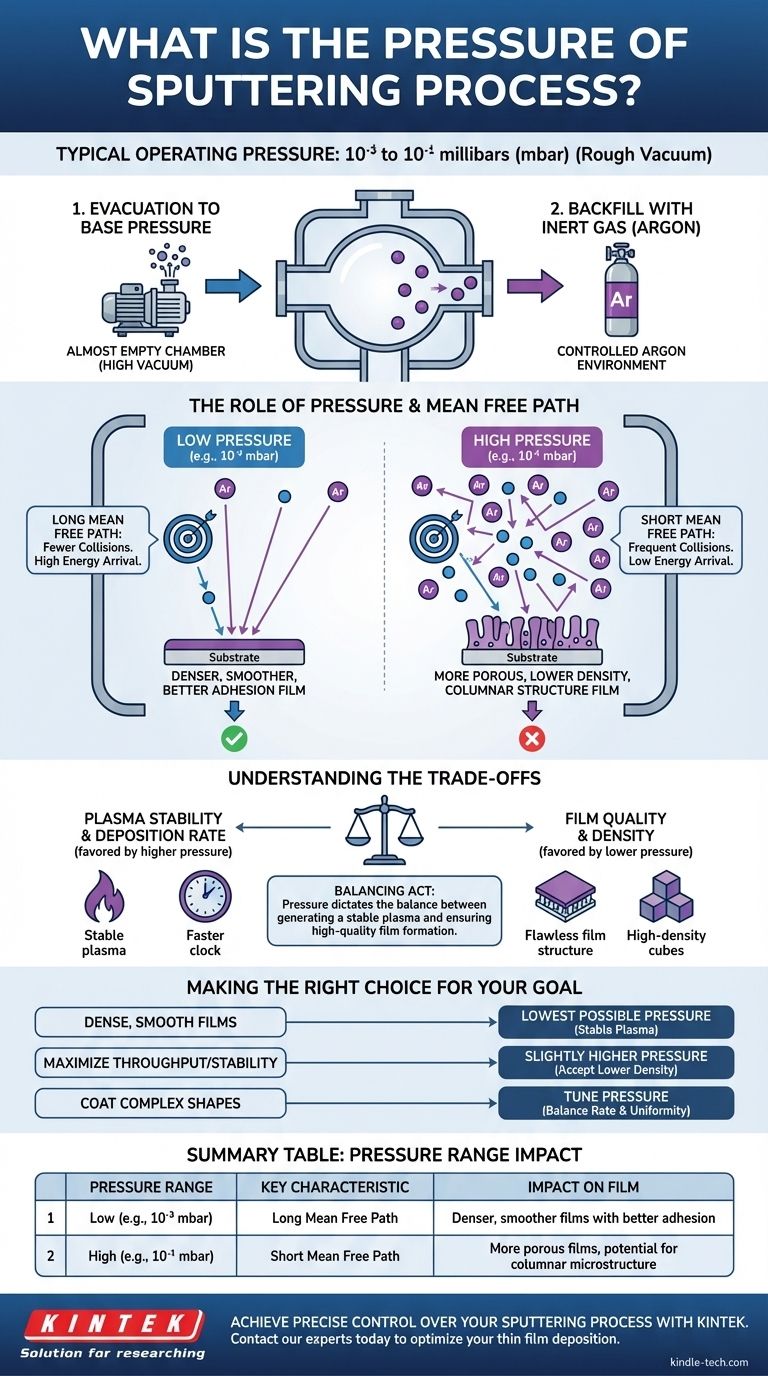

In short, the typical operating pressure for a sputtering process is a rough vacuum, generally in the range of 10⁻³ to 10⁻¹ millibars (mbar). This pressure is established by first evacuating the chamber to a much lower "base pressure" to remove contaminants, and then backfilling it with a controlled amount of an inert gas, most commonly Argon.

The core challenge of sputtering is not simply achieving a vacuum, but precisely controlling the gas pressure. This pressure dictates the balance between generating a stable plasma for sputtering and ensuring the sputtered atoms have enough energy when they reach the substrate to form a high-quality film.

The Role of Pressure in Sputtering

Sputtering relies on a carefully managed gas environment. The pressure of this gas, typically Argon, is one of the most critical parameters you can control.

Creating the Plasma

To begin, the process chamber must be nearly empty of reactive gases like oxygen or water vapor. This is achieved by pumping down to a high vacuum or "base pressure."

Once clean, the chamber is backfilled with a pure, inert gas like Argon. The pressure of this gas must be high enough to provide a sufficient number of atoms to ionize and sustain a plasma.

The Mean Free Path

Mean free path is the average distance an atom can travel before it collides with another atom. This concept is central to understanding the role of pressure.

At lower pressures, there are fewer gas atoms in the chamber. This results in a longer mean free path for the sputtered particles traveling from the target to the substrate.

Conversely, higher pressures mean more gas atoms and a shorter mean free path, leading to more frequent collisions.

How Pressure Directly Impacts Film Quality

The energy with which sputtered atoms arrive at the substrate surface is a primary determinant of the resulting film's properties. This arrival energy is directly controlled by the process pressure.

The Effect of Low Pressure

Operating at the lower end of the pressure range (e.g., 10⁻³ mbar) increases the mean free path.

Sputtered atoms experience fewer collisions as they travel to the substrate, allowing them to retain more of their initial kinetic energy. This high-energy arrival promotes surface mobility, resulting in films that are denser, smoother, and have better adhesion.

The Effect of High Pressure

Operating at higher pressures (e.g., 10⁻¹ mbar) shortens the mean free path significantly.

Sputtered atoms undergo numerous collisions with gas atoms, losing energy through a process called "gas scattering." These atoms arrive at the substrate with very low energy, which can lead to films that are more porous, have lower density, and may exhibit a columnar microstructure.

Understanding the Trade-offs

Optimizing sputtering pressure is a balancing act. Improving one characteristic often comes at the expense of another.

The Plasma Stability vs. Film Quality Conflict

You need enough gas pressure to easily ignite and sustain a stable plasma and achieve a practical deposition rate.

However, as we've seen, the pressure required for a robust plasma is often higher than what is ideal for creating a dense, high-energy film. This is the fundamental trade-off.

Deposition Rate and Uniformity

Higher pressure can increase the density of ions bombarding the target, which can increase the raw sputtering rate. However, the increased gas scattering can also deflect sputtered material away from the substrate, potentially lowering the effective deposition rate and impacting thickness uniformity, especially over large areas.

Contamination Risk

While the process starts at a low base pressure to remove contaminants, running the sputtering process at an extremely low pressure can make the system more sensitive to any residual gas or small leaks, potentially reintroducing impurities into the film over a long deposition run.

Making the Right Choice for Your Goal

The ideal pressure is determined entirely by the desired properties of your thin film.

- If your primary focus is dense, smooth, high-adhesion films: Operate at the lowest possible pressure that can still maintain a stable plasma.

- If your primary focus is maximizing throughput or ensuring plasma stability: You may need to use a slightly higher pressure, accepting a potential decrease in film density.

- If your primary focus is coating a large, complex shape: You must carefully tune the pressure to balance deposition rate and uniformity, as gas scattering can either help or hinder coverage depending on the geometry.

Ultimately, mastering the sputtering process involves a deep understanding of how to manipulate gas pressure to achieve your specific engineering objective.

Summary Table:

| Pressure Range | Key Characteristic | Impact on Film |

|---|---|---|

| Low (e.g., 10⁻³ mbar) | Long Mean Free Path | Denser, smoother films with better adhesion |

| High (e.g., 10⁻¹ mbar) | Short Mean Free Path | More porous films, potential for columnar microstructure |

Achieve precise control over your sputtering process with KINTEK.

Our advanced sputtering systems are engineered for exceptional pressure stability and control, enabling you to deposit high-quality, dense thin films with superior adhesion. Whether you're working on R&D or production, KINTEK's lab equipment and consumables are designed to meet the exacting demands of modern laboratories.

Ready to optimize your thin film deposition? Contact our experts today to discuss your specific application needs and discover how KINTEK can enhance your laboratory's capabilities.

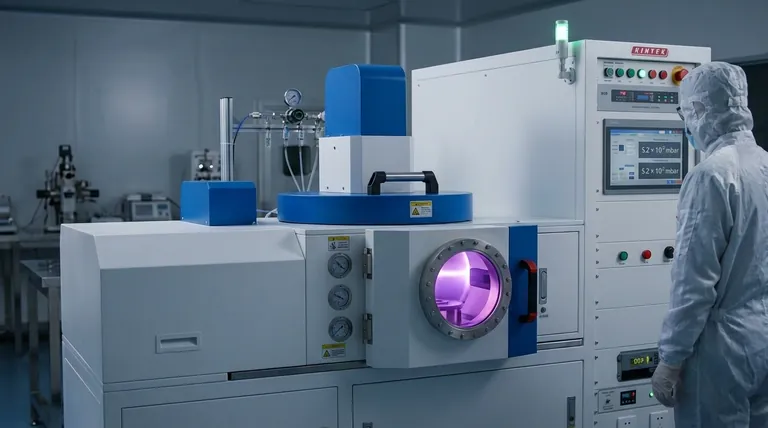

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What effects the deposition rate? Master the Key Variables for Optimal Sputtering

- What is CVD grown graphene? The Key to Scalable, High-Quality 2D Materials

- What is the difference between ALD and CVD? Precision vs. Speed in Thin Film Deposition

- What is the energy of sputtered atoms? Master the Key to Superior Thin Film Quality

- What is the cost of CVD process? A Guide to Justifying the Investment for Superior Films

- Why is MW-SWP CVD preferred for non-destructive graphene? Achieve Defect-Free Atomic Synthesis

- What is Metal-organic CVD (MOCVD) and what are its applications in CMOS? Enhance Your Semiconductor Precision

- How do you apply diamond-like carbon coating? Choose the Right Method for Your Engineering Needs