At its core, cold isostatic pressing (CIP) is a manufacturing process that compacts powders into a solid mass. It works by placing the powder inside a sealed, flexible mold, submerging it in a fluid-filled pressure chamber, and applying extremely high, uniform pressure to it from all directions at room temperature. This hydrostatic force causes the powder particles to bond together, forming a dense, solid component known as a "green body."

The fundamental purpose of cold isostatic pressing is not just compaction, but the achievement of exceptionally uniform density throughout a component. This uniformity, a direct result of applying equal pressure from all directions, eliminates many internal defects and stresses common in other pressing methods.

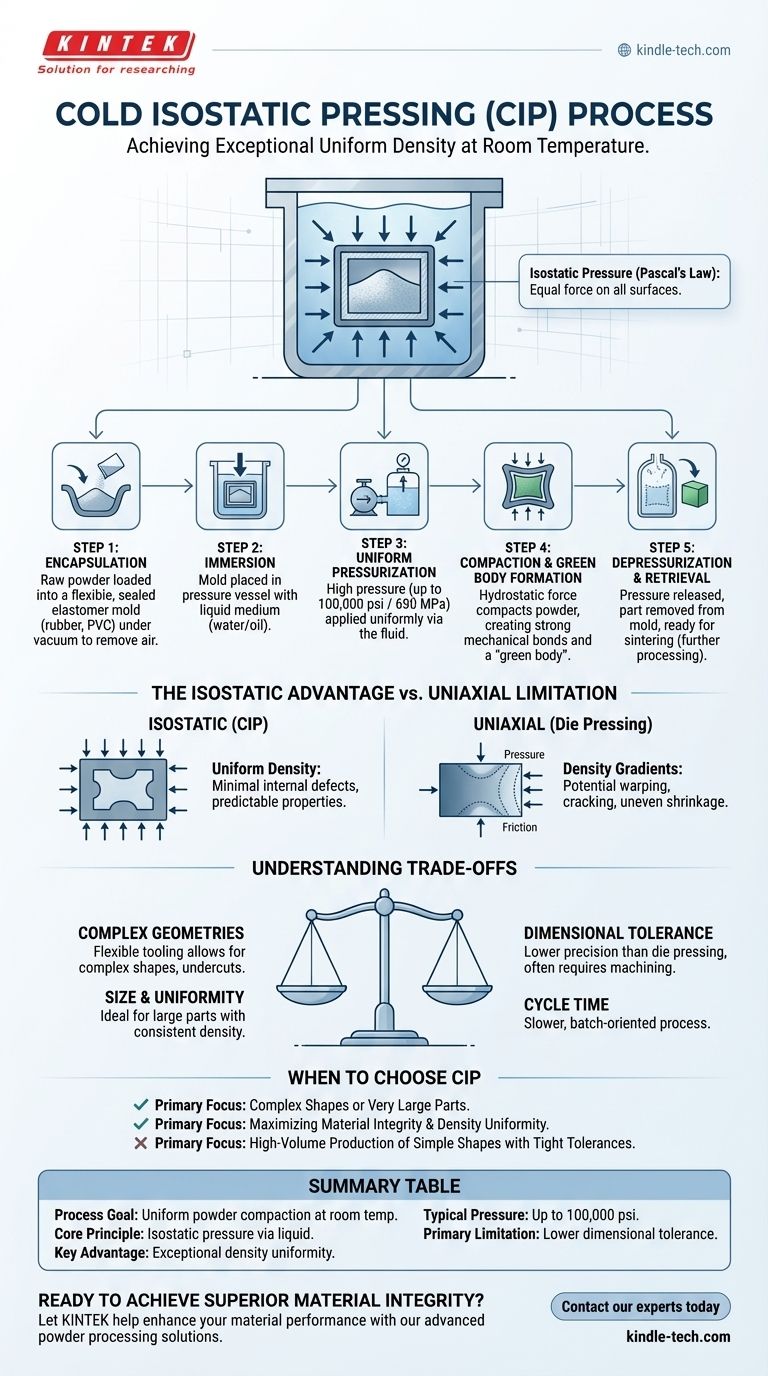

The CIP Process: A Step-by-Step Breakdown

To understand the value of CIP, it is essential to visualize its distinct stages. Each step is deliberately designed to ensure the final green compact possesses superior material integrity.

Step 1: Encapsulation in a Flexible Mold

The process begins by loading the raw powder material into a mold. Unlike the rigid steel dies of conventional pressing, CIP uses a flexible, watertight elastomer mold, typically made of rubber, urethane, or PVC. The mold is then sealed, often under vacuum, to remove any trapped air that could compromise density.

Step 2: Immersion in the Pressure Vessel

The sealed mold is placed inside a robust pressure vessel. This chamber is then filled with a liquid medium, which acts as the pressure-transmitting agent. This fluid is usually water mixed with a corrosion inhibitor or a specialized oil.

Step 3: Uniform Pressurization

An external high-pressure pump pressurizes the liquid inside the vessel. This pressure, which can reach up to 100,000 psi (approximately 690 MPa), is applied to the sealed mold. Because the pressure is transmitted through a fluid, it acts uniformly—or isostatically—on every single surface of the mold.

Step 4: Compaction and Green Body Formation

The immense hydrostatic pressure is transmitted through the flexible mold wall to the powder within. This force pushes the powder particles together, eliminating voids and creating strong mechanical bonds between them. The resulting solid, self-supporting component is called a green body, indicating it has handling strength but has not yet undergone its final heat treatment (sintering).

Step 5: Depressurization and Retrieval

After a predetermined hold time, the pressure is carefully released from the vessel. The liquid is drained, and the compacted part is removed from the chamber. The elastomer mold, which returns to its original shape, is stripped from the green body and can typically be reused.

The Principle: Isostatic vs. Uniaxial Pressure

The defining characteristic of CIP is its use of uniform pressure. This stands in stark contrast to more conventional methods and is the source of its primary advantages.

The Limitation of Uniaxial Pressing

In traditional die pressing, pressure is applied from one or two directions (uniaxially or biaxially). This creates friction between the powder and the rigid die walls, leading to significant density gradients. The areas furthest from the punch are less dense, which can cause warping, cracking, or uneven shrinkage during subsequent sintering.

The Isostatic Advantage

CIP leverages Pascal's Law, which states that pressure exerted on a confined fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel. By using a liquid to apply pressure, every part of the powder compact experiences the exact same force, eliminating the density variations caused by die-wall friction.

The Result: A Homogeneous Green Compact

The outcome is a green body with highly uniform density throughout its structure, regardless of its complexity or size. This homogeneity is critical for producing high-performance components that require predictable and consistent material properties after final processing.

Understanding the Trade-offs

While powerful, CIP is not a universal solution. A clear understanding of its advantages and limitations is crucial for proper application.

Advantage: Complex Geometries

Because the tooling is flexible, CIP can produce parts with complex shapes, undercuts, and hollow sections that are impossible to create with rigid dies.

Advantage: Size and Uniformity

CIP excels at producing very large parts with uniform density, as it is not limited by the mechanical constraints of a traditional press.

Limitation: Dimensional Tolerance

The use of a flexible mold means that CIP does not offer the same tight dimensional precision as die pressing. Green parts often require a machining step before sintering to meet final tolerance specifications.

Limitation: Cycle Time

The process of loading, sealing, pressurizing, and depressurizing makes CIP a slower, batch-oriented process compared to the high-speed, automated nature of die pressing. This makes it less suitable for high-volume production of simple components.

When to Choose Cold Isostatic Pressing

Your choice to use CIP should be driven by the final requirements of your component, weighing the need for material quality against production volume and cost.

- If your primary focus is producing complex shapes or very large parts: CIP is an excellent choice, as its flexible tooling is more adaptable and cost-effective than creating intricate hard dies.

- If your primary focus is maximizing material integrity and density uniformity: CIP is superior to uniaxial methods, as it minimizes internal defects and ensures consistent shrinkage during sintering.

- If your primary focus is high-volume production of simple shapes with tight tolerances: Traditional die pressing is often a more efficient and economical solution.

Ultimately, selecting cold isostatic pressing is a strategic decision to prioritize uniform material properties and geometric complexity over raw production speed.

Summary Table:

| Key Aspect | Details |

|---|---|

| Process Goal | Uniform powder compaction into a 'green body' at room temperature. |

| Core Principle | Isostatic (equal pressure from all directions) via liquid medium. |

| Key Advantage | Exceptional density uniformity, even in large or complex shapes. |

| Typical Pressure | Up to 100,000 psi (approx. 690 MPa). |

| Primary Limitation | Lower dimensional tolerance compared to die pressing. |

Ready to achieve superior material integrity in your components?

Cold isostatic pressing is the ideal solution for creating complex or large parts with uniform density and minimal internal defects. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including solutions for advanced powder processing like CIP. Our expertise helps laboratories and manufacturers overcome the limitations of traditional pressing methods.

Let KINTEK help you enhance your material performance. Contact our experts today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- How does isostatic pressing work? Achieve Perfectly Uniform Density for Complex Parts

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- What are the advantages of cold isostatic pressing? Achieve Superior Density and Complex Shapes

- What will happen if forging is carried out at very low temperature? Discover the Power of Cold Forging

- What is the difference between wet bag and dry bag isostatic pressing? Flexibility vs. High-Volume Production

- What is the pressing method in ceramics? A Guide to Shaping Dense, High-Performance Parts

- What is a cold press machine? A Guide to Uniform Powder Compaction Without Heat

- What is the pressure for cold isostatic pressing? Achieve Superior Density and Uniformity