In essence, Hot Isostatic Pressing (HIP) is a sophisticated manufacturing process that subjects components to high temperature and high, uniform pressure simultaneously. This is done inside a sealed, high-pressure vessel using an inert gas, most commonly argon, to eliminate internal porosity and consolidate materials, dramatically improving their mechanical properties without altering their shape.

Hot Isostatic Pressing is not simply a heating process; it is a method of internal purification. By applying uniform pressure from all directions at elevated temperatures, HIP effectively squeezes out internal voids and defects, transforming a standard component into a highly reliable, high-performance part.

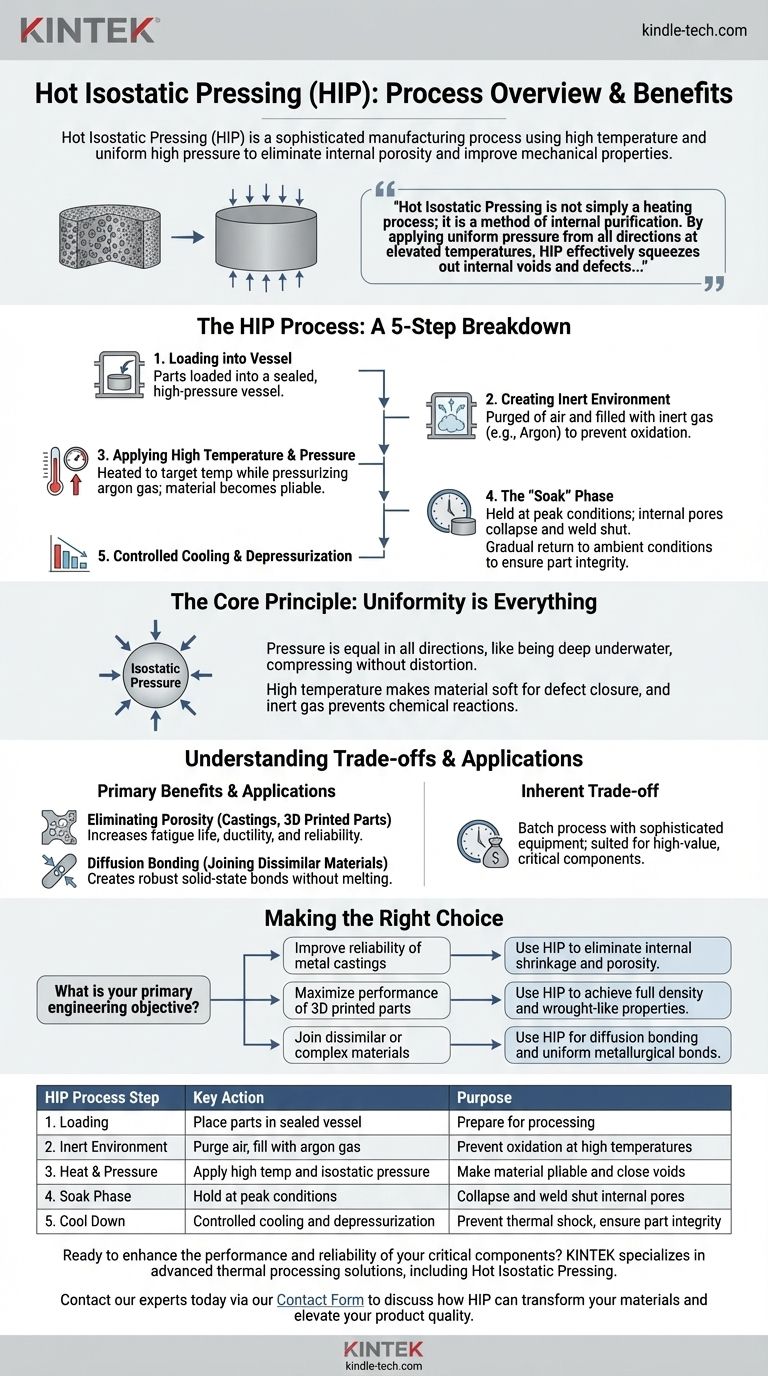

How Hot Isostatic Pressing Works: A Step-by-Step Breakdown

The HIP process is meticulously controlled from start to finish. Each step is precisely programmed to achieve specific material outcomes depending on the component and its intended application.

Step 1: Loading into the Vessel

Parts or components are carefully loaded into the HIP unit's pressure vessel. This chamber can range from small lab-scale units to massive vessels capable of holding tons of material.

Step 2: Creating the Inert Environment

Once sealed, the chamber is purged of air and filled with an inert gas, typically argon. This gas is critical because it prevents the material from oxidizing or reacting chemically at the extreme temperatures used in the process.

Step 3: Applying High Temperature and Pressure

The vessel is heated to the target temperature while the argon gas is simultaneously pressurized. The temperature lowers the material's yield strength, making it pliable, while the immense gas pressure acts on every surface of the component.

Step 4: The "Soak" Phase: Where Transformation Occurs

The component is held at the peak temperature and pressure for a specified duration, often called the "soak" time. During this phase, the combination of heat and uniform hydrostatic pressure causes internal pores and voids to collapse and weld shut.

Step 5: Controlled Cooling and Depressurization

After the soak is complete, the system begins a carefully controlled cool-down and depressurization cycle. This gradual return to ambient conditions is crucial to avoid thermal shock and ensure the integrity of the newly densified part.

The Core Principle: Uniformity is Everything

The "isostatic" part of the name is the key to understanding why this process is so effective. It means the pressure is equal in all directions.

What "Isostatic" Pressure Means

Imagine a component deep in the ocean. The water pressure acts on it uniformly from every possible angle. HIP creates a similar effect using high-pressure gas, ensuring that the part is compressed inward without distorting its overall shape.

The Role of High Temperature

Pressure alone is not enough. The high temperature makes the material soft enough for the gas pressure to physically close internal defects like gas porosity or shrinkage voids left over from casting or 3D printing.

Why an Inert Gas is Critical

Using a gas like argon ensures that the pressure medium is non-reactive. If regular air were used, the oxygen would cause severe oxidation on the material's surface at such high temperatures, ruining the component.

Understanding the Trade-offs and Applications

HIP is a powerful tool, but its value is best understood in the context of its primary applications and inherent trade-offs.

The Primary Benefit: Eliminating Porosity

The most common use of HIP is for densification. It is applied to critical metal castings and additively manufactured (3D printed) parts to remove internal porosity, which significantly increases fatigue life, ductility, and overall reliability.

A Key Application: Diffusion Bonding

HIP can be used to bond two or more different materials together without melting them. At the interface between the materials, the heat and pressure promote atomic diffusion, creating a solid-state bond that is often as strong as the parent materials themselves.

The Inherent Trade-off: Process Cost and Time

HIP is a batch process that requires sophisticated, expensive equipment and can take several hours from start to finish. This makes it best suited for high-value components where performance and reliability are non-negotiable.

Making the Right Choice for Your Goal

Applying HIP should be a deliberate decision based on a clear engineering objective.

- If your primary focus is improving the reliability of metal castings: Use HIP to eliminate internal shrinkage and gas porosity, dramatically increasing fatigue life and impact strength.

- If your primary focus is maximizing the performance of 3D printed metal parts: Use HIP as a post-processing step to achieve full density and unlock mechanical properties comparable to wrought materials.

- If your primary focus is joining dissimilar or complex materials: Use HIP for diffusion bonding to create a robust, uniform metallurgical bond without the issues associated with welding or brazing.

Ultimately, Hot Isostatic Pressing empowers you to engineer materials from the inside out, ensuring maximum density and performance.

Summary Table:

| HIP Process Step | Key Action | Purpose |

|---|---|---|

| 1. Loading | Place parts in sealed vessel | Prepare for processing |

| 2. Inert Environment | Purge air, fill with argon gas | Prevent oxidation at high temperatures |

| 3. Heat & Pressure | Apply high temp and isostatic pressure | Make material pliable and close voids |

| 4. Soak Phase | Hold at peak conditions | Collapse and weld shut internal pores |

| 5. Cool Down | Controlled cooling and depressurization | Prevent thermal shock, ensure part integrity |

Ready to enhance the performance and reliability of your critical components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing, to help you achieve maximum material density and superior mechanical properties. Whether you're working with high-value castings, additive manufacturing parts, or require diffusion bonding, our expertise and equipment are designed to meet the stringent demands of modern laboratories and manufacturing.

Contact our experts today via our Contact Form to discuss how HIP can transform your materials and elevate your product quality.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Cylindrical Press Mold with Scale for Lab

People Also Ask

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance