In essence, isostatic pressing is a powder metallurgy process that compacts powders into a solid mass using uniform pressure from all directions. A flexible, sealed mold filled with powder is submerged in a fluid inside a pressure vessel. As the fluid is pressurized, it applies equal force to every surface of the mold, creating a highly uniform and dense compacted part.

The critical advantage of isostatic pressing is its use of hydrostatic pressure, which eliminates the density variations and internal stresses common in traditional single-axis pressing, enabling the creation of complex shapes with superior material integrity.

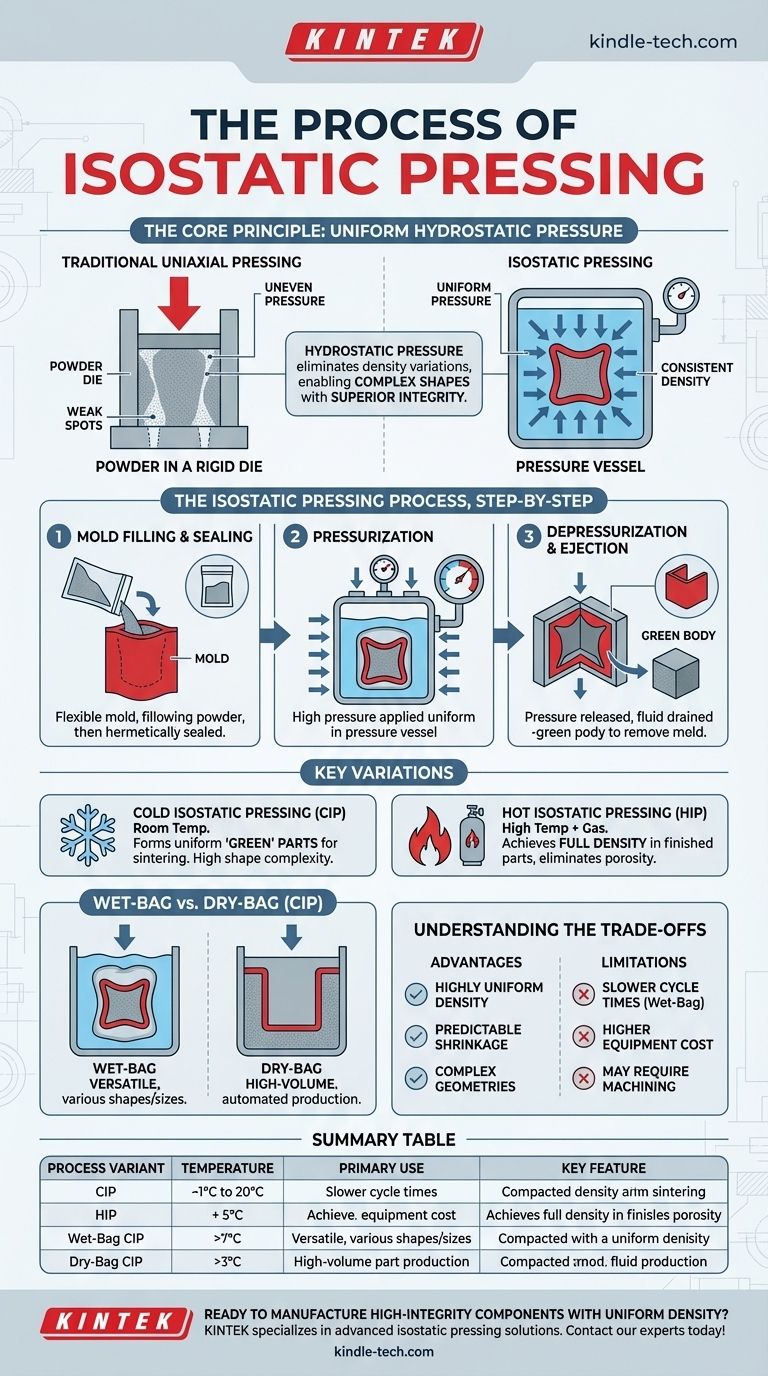

The Core Principle: Uniform Hydrostatic Pressure

Traditional powder compaction, known as uniaxial pressing, is like squeezing something in a vise. Pressure comes from only one or two directions, which can lead to uneven density and weak spots. Isostatic pressing solves this fundamental problem.

Why Uniform Pressure Matters

By applying pressure equally from all sides, the process ensures that powder particles are packed together with extreme uniformity. This minimizes internal voids, reduces the risk of cracks, and results in a final component with consistent and predictable mechanical properties throughout its structure.

The Role of the Flexible Mold

The powder is first loaded into a flexible, deformable mold made from materials like rubber, urethane, or plastic. This mold acts as a barrier to the pressurizing fluid but perfectly transmits the hydrostatic pressure to the powder within. The mold's flexibility allows the powder to be compacted into its net shape without the constraints of a rigid die.

The Isostatic Pressing Process, Step-by-Step

While variations exist, the fundamental process follows a clear sequence of operations designed for maximum uniformity.

Step 1: Mold Filling and Sealing

The process begins by carefully loading the raw powder into the flexible mold. The mold is then hermetically sealed to prevent any contamination from the pressurizing fluid.

Step 2: Pressurization

The sealed mold is placed inside a high-pressure vessel. The vessel is then filled with a fluid—typically a liquid for cold pressing or an inert gas for hot pressing. This fluid is pressurized, applying immense, uniform pressure to the entire exterior of the mold.

Step 3: Depressurization and Ejection

After a set time, the pressure is released, and the fluid is drained from the vessel. The container returns to its original shape, and the newly compacted part, often called a "green body," is carefully removed from the mold.

Key Variations of the Process

The term "isostatic pressing" covers a few distinct techniques, each suited for different applications and materials.

Cold Isostatic Pressing (CIP)

Cold Isostatic Pressing (CIP) is conducted at room temperature. Its primary purpose is to compact powder into a green body with sufficient strength and uniform density for handling and subsequent processing, such as machining or sintering.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) combines intense heat and high-pressure gas (usually argon) simultaneously. This process is used to achieve full theoretical density, eliminating any residual internal porosity in a component in a single step.

Wet-Bag vs. Dry-Bag (CIP)

CIP can be further divided into two methods. In the wet-bag process, the sealed mold is fully submerged in the pressurizing fluid, offering great versatility for various shapes and sizes. In the dry-bag process, the flexible mold is a permanent part of the pressure vessel, allowing for faster, more automated production cycles.

Understanding the Trade-offs

Like any manufacturing process, isostatic pressing has distinct advantages and limitations that make it suitable for specific applications.

Key Advantages

The primary benefit is highly uniform density, which leads to predictable shrinkage during sintering and excellent mechanical properties. It also allows for the creation of complex geometries, including undercuts and long, slender parts that are impossible with traditional die compaction.

Common Limitations

Isostatic pressing generally has slower cycle times compared to high-speed uniaxial pressing, especially for the wet-bag method. The initial equipment cost is also significantly higher. Finally, achieving tight dimensional tolerances often requires secondary machining operations after pressing.

Making the Right Choice for Your Goal

Selecting the correct process variant depends entirely on your material, the component's complexity, and your final performance requirements.

- If your primary focus is creating complex green parts with uniform density for sintering: Cold Isostatic Pressing (CIP) is the ideal and most common choice.

- If your primary focus is achieving full theoretical density and superior mechanical properties in a finished part: Hot Isostatic Pressing (HIP) is the necessary method to eliminate all internal voids.

- If your primary focus is high-volume production of simpler shapes via CIP: The automated dry-bag process offers a significant speed advantage over the more versatile wet-bag technique.

By leveraging uniform, all-encompassing pressure, isostatic pressing delivers a powerful solution for manufacturing high-integrity components from powders.

Summary Table:

| Process Variant | Temperature | Primary Use | Key Feature |

|---|---|---|---|

| Cold Isostatic Pressing (CIP) | Room Temp | Forming uniform 'green' parts for sintering | High shape complexity, uniform density |

| Hot Isostatic Pressing (HIP) | High Temp | Achieving full density in finished parts | Eliminates porosity, superior properties |

| Wet-Bag CIP | Room Temp | Versatile, various shapes/sizes | Flexible mold submerged in fluid |

| Dry-Bag CIP | Room Temp | High-volume, automated production | Mold is permanent part of vessel |

Ready to manufacture high-integrity components with uniform density? KINTEK specializes in advanced isostatic pressing solutions for your laboratory and production needs. Whether you require Cold Isostatic Pressing (CIP) for complex green parts or Hot Isostatic Pressing (HIP) for fully dense components, our expertise in lab equipment and consumables ensures optimal results. Contact our experts today to discuss how our isostatic pressing technology can enhance your material properties and production capabilities!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- Is isostatic pressing expensive? Achieve Superior Material Uniformity & Complex Shapes

- How is isostatic pressing distinguished from conventional pressing? Unlock Superior Uniformity and Density

- What products are made by isostatic pressing? Achieve Flawless, High-Performance Components

- What is cold isostatic pressing? Achieve Uniform Density for Complex Parts

- Why is a cold isostatic press advantageous for Argyrodite sulfide solid-state batteries? Achieve Optimal Densification

- What is the pressure for isostatic ceramics? Achieve Uniform Density for Superior Ceramic Parts

- How does a Cold Isostatic Press (CIP) contribute to the fabrication of HE-O-MIEC and LLZTO? Expert Densification Guide

- Why is a Cold Isostatic Press (CIP) Preferred for Sulfide Solid Electrolytes? Maximize Your Ionic Conductivity