At its core, press sintering is a manufacturing process that transforms powder into a solid object. It achieves this by first compacting the powder into a desired shape under immense pressure, and then heating this compacted form to a temperature below its melting point. This heat causes the individual powder particles to fuse together, dramatically increasing the object's density and strength.

The central principle of sintering is to bypass the need to fully melt a material. Instead, it uses a precise combination of pressure and heat to compel individual particles to bond at an atomic level, creating strong, near-net-shape components directly from a powder base.

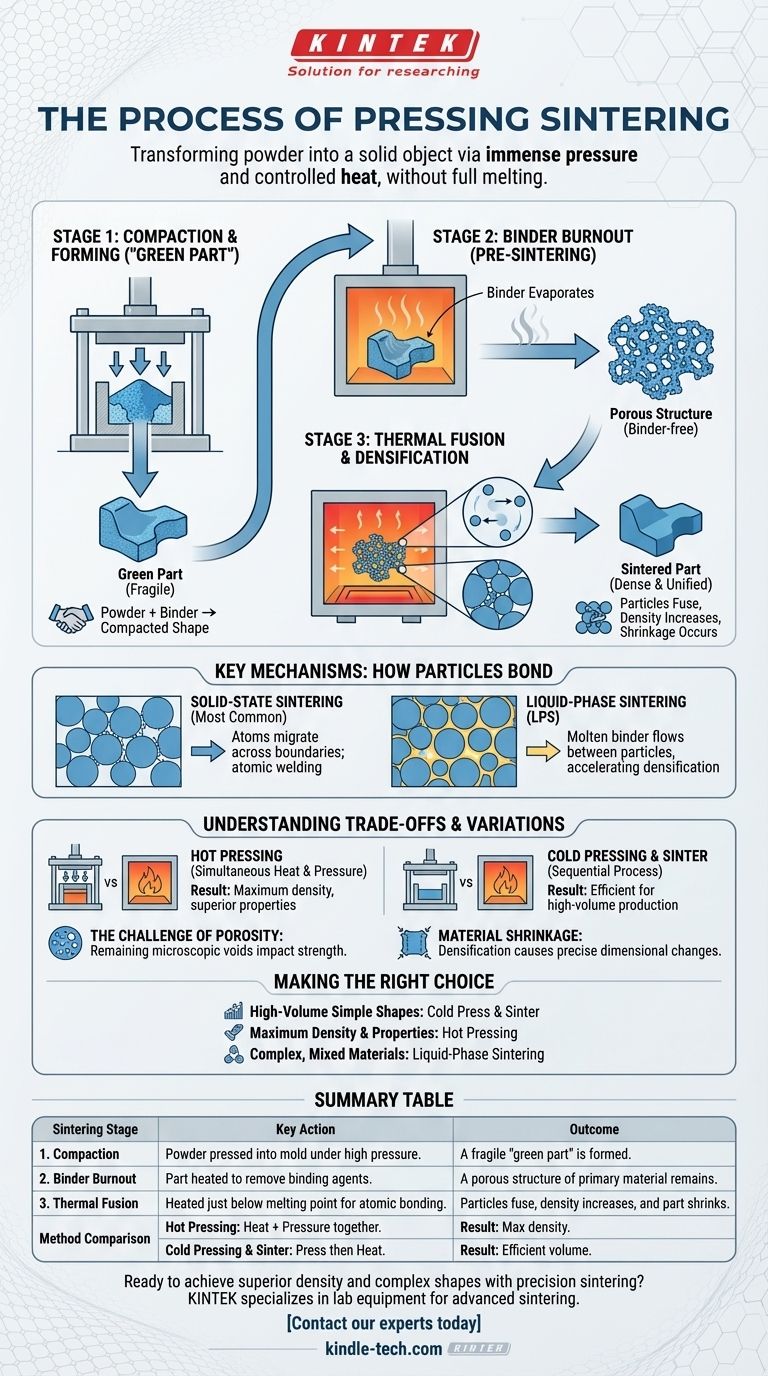

The Three Foundational Stages of Sintering

To understand how a loose powder becomes a durable, solid part, we must examine the process in its distinct stages. Each step serves a critical function in the material's transformation.

Stage 1: Compaction and Forming the "Green Part"

The process begins by filling a mold or die with a carefully prepared powder blend. This blend often includes the primary material powder along with a bonding agent, such as wax or a polymer.

High pressure is then applied to compact the powder, forcing the particles into tight contact. This creates a fragile, precisely shaped object known as a "green part," which has enough mechanical integrity to be handled.

Stage 2: Binder Burnout (Pre-Sintering)

The green part is then gently heated in a controlled-atmosphere furnace. During this phase, the primary goal is to remove the bonding agent added in the first stage.

The binder either evaporates or burns away cleanly, leaving behind a porous structure composed solely of the primary material particles, now ready for permanent fusion.

Stage 3: Thermal Fusion and Densification

As the temperature continues to rise to just below the material's melting point, the atoms at the surface of the particles become highly active. They begin to migrate across the boundaries between particles, creating strong atomic bonds.

This atomic diffusion pulls the particles closer together, shrinking the part slightly and significantly reducing the empty space, or porosity, between them. The result is a single, densified, and unified mass.

Key Mechanisms: How Particles Actually Bond

While the process seems straightforward, the actual fusion at the microscopic level can occur in two primary ways. The chosen method depends on the materials involved and the desired final properties.

Solid-State Sintering

This is the most common form of sintering. Here, the particles of the primary material fuse directly to one another without any melting occurring.

The combination of heat and pressure provides enough energy for atoms to move across particle boundaries, effectively welding them together into a solid crystalline structure.

Liquid-Phase Sintering (LPS)

In some cases, a secondary material with a lower melting point is mixed with the primary powder. During heating, this secondary material melts while the primary particles remain solid.

This molten liquid acts as a bonding agent, flowing into the gaps between the solid particles and accelerating densification. For example, bronze might be used to bond tungsten particles, which have a much higher melting point.

Understanding the Trade-offs and Variations

Like any manufacturing process, sintering is not a single, one-size-fits-all technique. The specific application of heat and pressure defines the outcome and suitability for a given task.

Hot Pressing vs. Cold Pressing

The most common method involves cold pressing the powder at room temperature and then sintering it in a separate furnace step. This is efficient for high-volume production.

Hot pressing, by contrast, applies heat and pressure simultaneously. This highly unbalanced process is more complex but can achieve greater density by breaking down surface oxide layers on the powder and activating the material more effectively.

The Challenge of Porosity

While sintering dramatically reduces the empty space between particles, it rarely eliminates it entirely. The remaining microscopic porosity can impact the final mechanical properties of the part, such as its strength and durability.

Controlling and minimizing porosity is a central challenge in powder metallurgy and ceramics manufacturing.

Material Shrinkage

The densification that occurs during the final heating stage inevitably causes the component to shrink. This shrinkage must be precisely calculated and accounted for in the initial design of the mold and the green part to ensure the final product meets dimensional specifications.

Making the Right Choice for Your Goal

Selecting the appropriate sintering approach is critical for achieving the desired outcome, whether for ceramics, metals, or composite materials.

- If your primary focus is high-volume production of simple metal shapes: The standard cold press and sinter process is highly efficient and cost-effective.

- If your primary focus is achieving maximum density and superior material properties: Hot pressing is the superior choice, as it more effectively eliminates porosity.

- If your primary focus is creating complex components from mixed materials: Liquid-phase sintering provides a powerful way to bond dissimilar materials that cannot be alloyed traditionally.

Ultimately, mastering the sintering process allows for the precise fabrication of durable components that are often impossible to create through conventional melting and casting.

Summary Table:

| Sintering Stage | Key Action | Outcome |

|---|---|---|

| 1. Compaction | Powder is pressed into a mold under high pressure. | A fragile "green part" is formed. |

| 2. Binder Burnout | The part is heated to remove binding agents. | A porous structure of primary material remains. |

| 3. Thermal Fusion | Heated to just below melting point for atomic bonding. | Particles fuse, density increases, and part shrinks. |

| Method Comparison | Hot Pressing | Cold Pressing & Sinter |

| Heat and pressure applied simultaneously. | Pressing at room temperature, then sintering. | |

| Result: Maximum density, superior properties. | Result: Efficient for high-volume production. |

Ready to achieve superior density and complex shapes with precision sintering?

At KINTEK, we specialize in the lab equipment and consumables that make advanced sintering processes possible. Whether you are developing new metal alloys, ceramic components, or composite materials, our solutions help you control porosity, manage shrinkage, and achieve the material properties you need.

Let's discuss your project. Contact our experts today to find the right sintering equipment for your laboratory's specific challenges.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What role does the high vacuum environment play in sintering graphite film/aluminum composites? Optimize Your Bonding

- Which conditions does a vacuum hot-pressing furnace provide for TiB2-TiN-WC ceramic tools? Achieve 98.7% Density

- What technical advantages does a vacuum hot-pressing furnace offer for Ti/Al2O3 composites? Achieve 99% Density

- Why is it essential to maintain a high vacuum state during hot press sintering? Optimize SiCp/2024Al Quality

- How does a vacuum hot pressing furnace optimize Ni-Co-Al density? Achieve 97.6% Relative Density via Precision Control