At its core, vacuum deposition is a family of processes used to apply extremely thin, high-performance coatings of material onto an object, known as a substrate. These processes all take place inside a vacuum chamber, which is the key to their function. This technology is fundamental to manufacturing a vast range of modern products, from the anti-reflection coatings on your eyeglasses to the complex layers inside a computer chip.

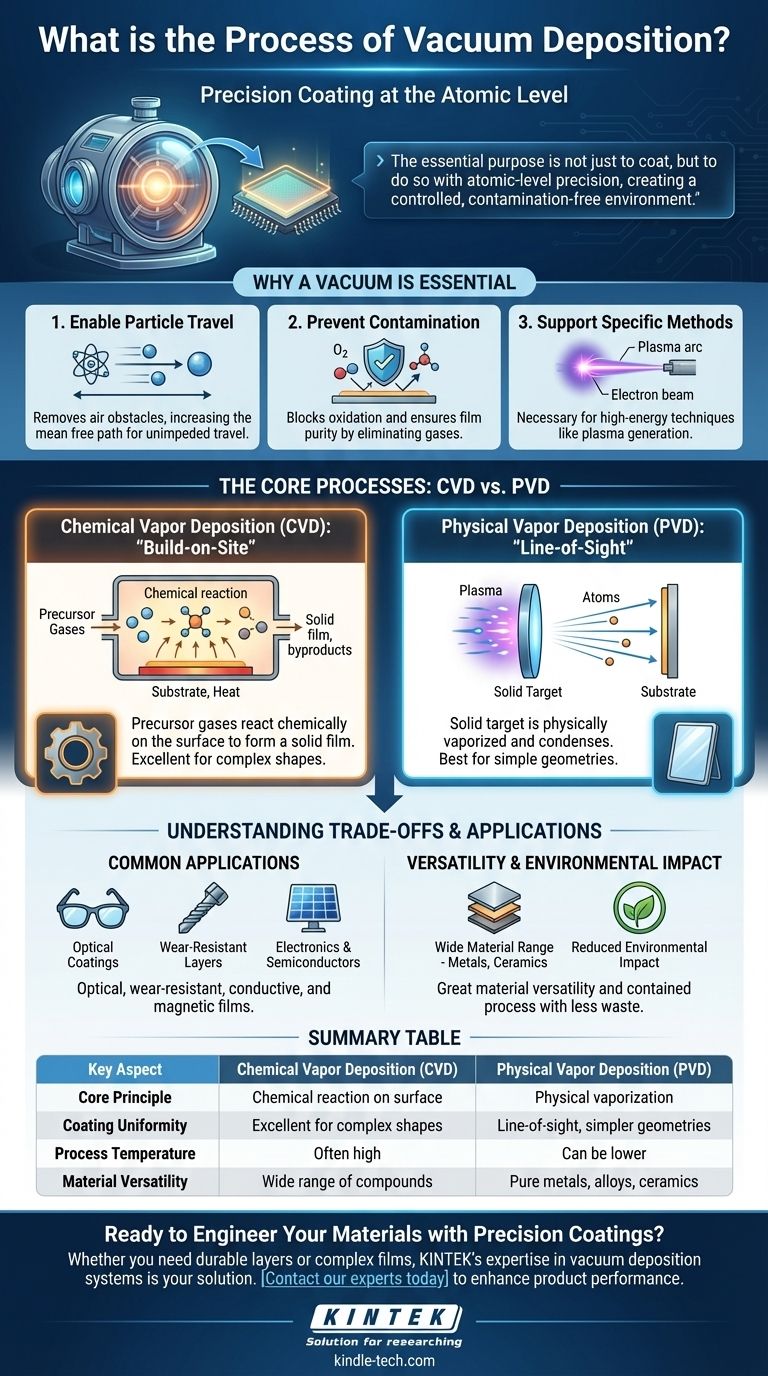

The essential purpose of vacuum deposition is not just to coat a surface, but to do so with atomic-level precision. By removing air and other gases, a vacuum creates a controlled, contamination-free environment, allowing vaporized coating material to travel unimpeded from its source to the substrate.

Why a Vacuum is Essential

The vacuum itself is not just an empty space; it is an active tool that enables the entire process. Without it, depositing high-quality thin films would be impossible for three primary reasons.

To Enable Particle Travel

At normal atmospheric pressure, vaporized atoms or molecules from the coating material would collide with air molecules billions of time per second.

Their average travel distance, known as the mean free path, would be less than a millimeter. A vacuum removes these obstacles, allowing the coating particles to travel in a straight line directly to the substrate.

To Prevent Contamination and Oxidation

Many materials, especially when heated to a vapor state, will instantly react with oxygen and other gases in the air.

This oxidation and contamination would ruin the chemical purity and performance of the final coating. The vacuum ensures the film being deposited is made of only the intended material.

To Support Specific Deposition Methods

Many of the high-energy techniques used to vaporize the source material can only function in a vacuum. These conditions are necessary to generate and control the plasmas or electron beams required for certain processes.

The Core Processes: Physical vs. Chemical

While there are many specific techniques, they generally fall into two major categories: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD).

Chemical Vapor Deposition (CVD): The "Build-on-Site" Method

In CVD, the substrate is placed in the vacuum chamber and exposed to one or more volatile precursor gases. These gases are not the final coating material itself, but rather the chemical ingredients.

A chemical reaction is then induced on the substrate's surface, often by high temperature. This reaction breaks the gases down and forms a solid film on the substrate, with excess byproducts being pumped away. The process involves a sequence of steps including gas transport, adsorption onto the surface, chemical reaction, and growth of the film.

Physical Vapor Deposition (PVD): The "Line-of-Sight" Method

In PVD, the coating material starts as a solid. This solid "target" is physically transformed into a vapor, which then travels through the vacuum and condenses on the substrate, forming the film. There is no chemical reaction on the surface.

A common PVD method is sputtering. In this process, a high-energy ion plasma bombards the solid target, physically knocking atoms off its surface. These "sputtered" atoms fly across the chamber and deposit onto the substrate. The typical industrial process involves preparing the vacuum, cleaning the substrate, performing the coating, and returning the chamber to ambient conditions.

Understanding the Trade-offs and Applications

Choosing between different vacuum deposition methods depends entirely on the desired properties of the final coating and the nature of the substrate material.

Common Applications

The precision of vacuum deposition makes it indispensable across numerous industries. It is used for optical and mirror coatings, wear-resistant layers on cutting tools, corrosion-protective barriers, and decorative finishes.

In electronics, it is critical for creating the electrically conducting films, semiconductor layers, and magnetic films used in everything from solar cells to hard drives.

Versatility and Environmental Impact

Compared to traditional wet-chemical coating methods like electroplating, vacuum deposition offers immense versatility in the materials that can be deposited, including metals, alloys, ceramics, and compounds.

Furthermore, these processes have a greatly reduced environmental impact. They are contained within a sealed chamber and use very small quantities of material, producing far less hazardous waste.

Making the Right Choice for Your Goal

Selecting a deposition process requires balancing the material requirements, component geometry, and cost.

- If your primary focus is creating a highly uniform coating on complex, non-flat shapes: CVD is often the superior choice because the precursor gases can flow and react on all exposed surfaces.

- If your primary focus is depositing a wide range of pure metals, alloys, or compounds at lower temperatures: PVD methods like sputtering offer unmatched versatility and are less likely to damage heat-sensitive substrates.

- If your primary focus is durability and hardness: Both PVD and CVD can produce exceptionally hard, wear-resistant coatings, with the specific choice depending on the material and application.

Ultimately, vacuum deposition provides a powerful toolkit for engineering the surfaces of materials with atomic precision.

Summary Table:

| Key Aspect | Chemical Vapor Deposition (CVD) | Physical Vapor Deposition (PVD) |

|---|---|---|

| Core Principle | Chemical reaction on the substrate surface | Physical vaporization of a solid target |

| Coating Uniformity | Excellent for complex, non-flat shapes | Line-of-sight, best for simpler geometries |

| Typical Applications | Semiconductor layers, wear-resistant coatings | Optical coatings, decorative finishes |

| Process Temperature | Often high temperature | Can be lower temperature |

| Material Versatility | Wide range of compounds | Pure metals, alloys, ceramics |

Ready to Engineer Your Materials with Precision Coatings?

Whether you need durable, wear-resistant layers for cutting tools, complex semiconductor films for electronics, or high-performance optical coatings, KINTEK's expertise in vacuum deposition systems is your solution. We specialize in providing advanced lab equipment and consumables tailored to your specific research and production goals.

Contact our experts today to discuss how our vacuum deposition solutions can enhance your product performance and efficiency.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition