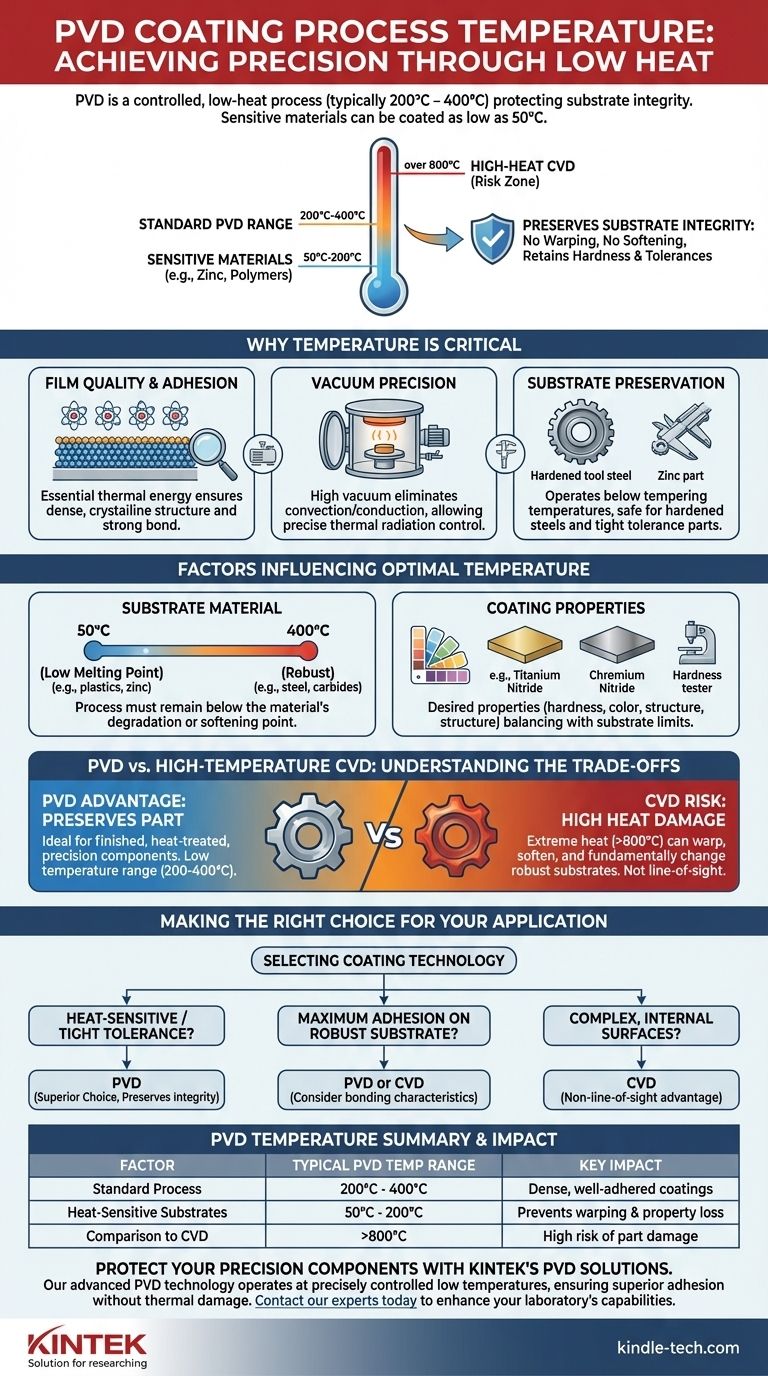

The process temperature for Physical Vapor Deposition (PVD) coating is not a single value but a controlled range, typically between 200°C and 400°C. However, for more sensitive materials like zinc or certain polymers, the temperature can be maintained as low as 50°C. This relatively low operating temperature is a defining characteristic of PVD and is a primary reason for its selection over other coating methods.

PVD's key advantage lies not just in the coating it creates, but in the low-heat process it uses. This prevents the substrate from warping, softening, or losing its critical heat-treated properties, making it ideal for precision components and heat-sensitive materials.

Why Temperature Is a Critical Control Parameter

Temperature is one of the most crucial variables in the PVD process. It directly influences the quality, adhesion, and final properties of the deposited thin film.

The Role of Temperature in Film Quality

While PVD is a "low-temperature" process, a certain amount of thermal energy is essential. This energy allows the deposited atoms to arrange themselves into a dense, uniform, and well-adhered crystalline structure on the component's surface.

Improper temperature control can result in a film that is porous, poorly bonded, or has high internal stress, leading to premature failure.

A Vacuum-Based Process

PVD is conducted in a high-vacuum chamber. In this environment, heat transfer through convection and conduction is eliminated, leaving only thermal radiation.

This gives process engineers extremely precise control over the part's temperature, ensuring that heat is applied intentionally and uniformly, rather than as an uncontrolled byproduct of the environment.

Preserving Substrate Integrity

The ability to operate below the tempering or annealing temperature of most materials is PVD's most significant thermal advantage.

This means that components made from hardened tool steels, for example, can be coated without losing their hardness. Similarly, parts with very tight dimensional tolerances will not warp or distort during the coating cycle.

Factors Influencing PVD Process Temperature

The optimal temperature for a PVD run is determined by a combination of the substrate material and the desired outcome of the coating itself.

Substrate Material

This is the most dominant factor. The process must remain well below the temperature at which the substrate material begins to degrade, soften, or change its properties.

Materials with low melting points, such as zinc alloys or plastics, require process temperatures at the lowest end of the PVD spectrum (50°C - 200°C). In contrast, robust materials like steel or carbides can easily tolerate the higher end of the range.

Coating Material and Properties

Different coating materials (e.g., Titanium Nitride, Chromium Nitride) and their desired final characteristics—such as hardness, color, or structure—have optimal deposition temperatures. The engineer must balance the ideal temperature for the coating with the thermal limits of the substrate.

Understanding the Trade-offs: PVD vs. High-Temperature CVD

The choice between PVD and a high-temperature alternative like Chemical Vapor Deposition (CVD) often comes down to the role of temperature.

The PVD Advantage: Preserving the Part

PVD's low temperature range makes it the default choice for finished, precision components. It is ideal for coating parts that have already been heat-treated or cannot tolerate any dimensional change, such as cutting tools, injection molding components, and optical parts.

The CVD Context: When High Heat is Acceptable

CVD processes operate at much higher temperatures, often exceeding 800°C. This extreme heat facilitates a chemical reaction that can produce exceptionally hard and tenacious coatings.

However, this process is only suitable for materials that can withstand such temperatures without softening or deforming. It is also not a line-of-sight process, giving it an advantage for coating complex internal geometries where PVD cannot reach.

The Primary Risk: Distortion and Material Damage

The key trade-off is component integrity. Choosing a process that is too hot for your substrate will irrevocably damage the part, causing it to lose hardness, warp out of tolerance, or fundamentally change its mechanical properties. PVD mitigates this risk almost entirely.

Making the Right Choice for Your Application

Selecting the correct coating technology requires matching the process parameters to your component's material and function.

- If your primary focus is coating heat-sensitive materials or parts with tight tolerances: PVD is the superior choice because its low process temperature preserves the component's integrity and dimensions.

- If your primary focus is achieving maximum coating adhesion on a robust substrate that can withstand extreme heat: Both PVD and CVD are viable, but CVD's high-temperature chemical reaction may offer different bonding characteristics.

- If your primary focus is coating complex, non-line-of-sight internal surfaces: A non-line-of-sight process like Chemical Vapor Deposition (CVD) is likely more suitable than PVD.

Ultimately, understanding the role of temperature empowers you to select a coating process that protects not only the surface but the fundamental integrity of your entire component.

Summary Table:

| Factor | Typical PVD Temperature Range | Key Impact |

|---|---|---|

| Standard Process | 200°C - 400°C | Dense, well-adhered coatings |

| Heat-Sensitive Substrates | 50°C - 200°C | Prevents warping & property loss |

| Comparison to CVD | >800°C | High risk of part damage |

Protect your precision components with KINTEK's PVD coating solutions.

Our advanced PVD technology operates at precisely controlled low temperatures to ensure your parts retain their hardness, dimensional accuracy, and critical properties. Whether you're working with hardened tool steels, zinc alloys, or polymers, KINTEK's lab equipment and consumables are designed to deliver superior coating adhesion without thermal damage.

Contact our experts today to discuss how our PVD processes can enhance your laboratory's capabilities and safeguard your most valuable components.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use