At its core, the purpose of sintering is to transform a fragile, compacted ceramic powder into a solid, dense, and strong object. This is accomplished by applying intense heat that is high enough to fuse the powder particles together, but crucially, below the material's melting point. This single process is what gives a ceramic component its final mechanical strength and engineered properties.

A ceramic object formed from powder, known as a "green body," is weak and full of pores. Sintering is the critical manufacturing step that eliminates these pores, bonding the material into a dense and durable final part without having to melt and cast it.

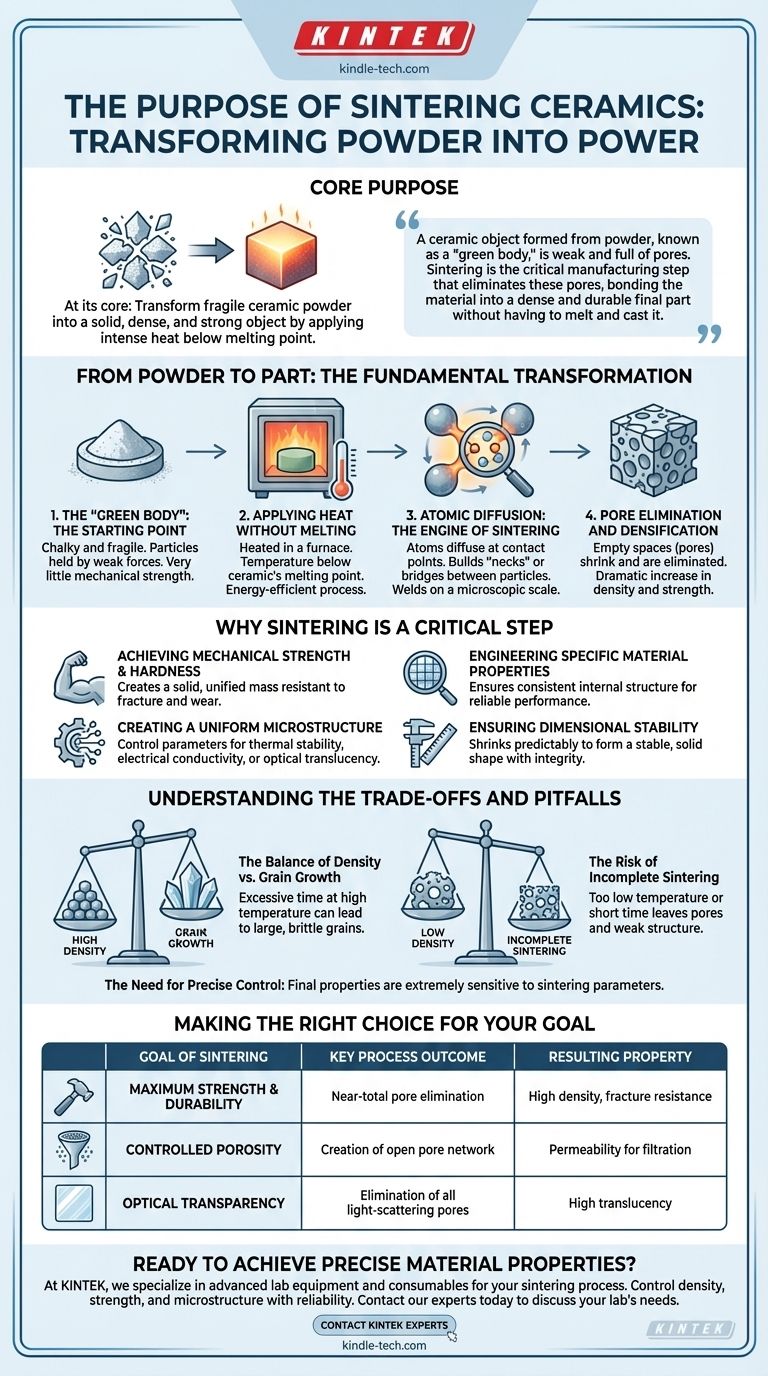

From Powder to Part: The Fundamental Transformation

Sintering is not just heating; it's a controlled atomic-level process. Understanding this transformation reveals why it is so essential for creating high-performance ceramics.

The "Green Body": The Starting Point

The process begins with ceramic powder that is compressed into a desired shape. This initial object, called a green body, is chalky and fragile. It holds its shape but possesses very little mechanical strength because the individual particles are only held together by weak physical forces.

Applying Heat Without Melting

The green body is placed in a furnace and heated to a specific, high temperature. This temperature is carefully selected to be below the ceramic's melting point. This is a key advantage, making the process more energy-efficient and suitable for high-melting-point materials like ceramics.

Atomic Diffusion: The Engine of Sintering

At this elevated temperature, the atoms at the contact points between the powder particles become highly active. They begin to diffuse, or move, across the boundaries of adjacent particles. This atomic movement effectively builds "necks" or bridges between the particles, welding them together on a microscopic scale.

Pore Elimination and Densification

As particles fuse, the empty spaces, or pores, between them gradually shrink and are eliminated. This process, known as densification, is the primary goal of most sintering operations. The removal of porosity is directly responsible for the dramatic increase in the material's density and strength.

Why Sintering is a Critical Step in Ceramics

The changes that occur during sintering are what unlock the unique and valuable properties of ceramic materials. Without it, you simply have a compressed powder brick.

Achieving Mechanical Strength and Hardness

By fusing particles and removing pores, sintering creates a solid, unified mass. This dense structure is far more resistant to fracture and wear, resulting in the high mechanical strength and hardness that ceramics are known for.

Engineering Specific Material Properties

The process is highly controllable. By carefully managing parameters like temperature, time, and atmosphere, engineers can precisely tailor the final properties. This includes optimizing for thermal stability, electrical conductivity (or insulation), and even optical translucency.

Creating a Uniform Microstructure

Successful sintering produces a consistent internal structure, or microstructure, throughout the ceramic part. This uniformity is critical for ensuring reliable and predictable performance, especially in demanding applications like cutting tools or electrical insulators.

Ensuring Dimensional Stability

As the material densifies, it shrinks in a predictable way to form a stable, solid shape. This final sintered part will maintain its dimensions and integrity under service conditions.

Understanding the Trade-offs and Pitfalls

While powerful, sintering is a delicate balance. Controlling the process is key to avoiding defects and achieving the desired outcome.

The Balance of Density vs. Grain Growth

The primary goal is usually to increase density by removing pores. However, if the material is held at a high temperature for too long, the individual crystal grains can begin to grow excessively large. This can sometimes make the material more brittle, so engineers must balance achieving high density with controlling grain growth.

The Risk of Incomplete Sintering

If the temperature is too low or the time is too short, the particles will not fully fuse. The resulting part will remain porous, weak, and will not meet its performance specifications.

The Need for Precise Control

The final properties of a ceramic are extremely sensitive to the sintering parameters. Slight variations in the heating cycle can lead to significant differences in density, strength, and other characteristics, making process control paramount for quality.

Making the Right Choice for Your Goal

The specific objective of sintering can be fine-tuned based on the intended application of the final ceramic component.

- If your primary focus is maximum strength and durability: Your goal is to achieve the highest possible density by eliminating nearly all porosity, creating a robust part for applications like ceramic bearings or cutting tools.

- If your primary focus is controlled porosity: You will use sintering to create a strong, bonded structure that intentionally leaves a network of open pores, essential for products like ceramic filters.

- If your primary focus is optical transparency: You must achieve near-total pore elimination, as even microscopic pores will scatter light and cause opacity, a critical requirement for transparent armor or specific lenses.

Ultimately, mastering the sintering process is mastering the ability to engineer a ceramic material's final form and function.

Summary Table:

| Goal of Sintering | Key Process Outcome | Resulting Property |

|---|---|---|

| Maximum Strength & Durability | Near-total pore elimination | High density, fracture resistance |

| Controlled Porosity | Creation of open pore network | Permeability for filtration |

| Optical Transparency | Elimination of all light-scattering pores | High translucency |

| Electrical/Thermal Control | Tailored microstructure | Specific conductivity or insulation |

Ready to achieve precise material properties with your ceramic components?

At KINTEK, we specialize in the advanced lab equipment and consumables needed to perfect your sintering process. Whether you're developing cutting tools, filters, or transparent ceramics, our solutions help you control density, strength, and microstructure with reliability.

Contact our experts today to discuss how we can support your laboratory's sintering and ceramic manufacturing needs.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is density important in ceramics? It's the Key to Mechanical Strength and Performance

- Is ceramic chemically inert? Unlock the Power of Ultimate Chemical Resistance

- What temperature is ceramic membrane sintering? A Guide from 750°C to 2100°C+

- How does silicon carbide work? Powering Next-Gen Electronics with Extreme Efficiency

- What is the melting temperature of ceramics? Understanding High-Temperature Material Performance

- What is the process of sintering in ceramic materials? A Guide to Transforming Powder into High-Strength Parts

- What material is used for pusher plates? Discover Mullite's Superior Chemical and Thermal Shock Resistance

- What is the advantage of ceramic over metal? Unlock Superior Performance in Extreme Conditions