In short, a vulcanizing machine's purpose is to apply precise heat and pressure to rubber or plastic products, initiating a chemical process called vulcanization. This process fundamentally transforms the material, converting it from a soft, weak substance into a strong, durable, and elastic finished product.

The machine is not merely a heater or a press; it is a highly controlled environment designed to execute a specific chemical reaction. Its true purpose is to turn a raw, limited material into a high-performance engineered component with predictable and reliable properties.

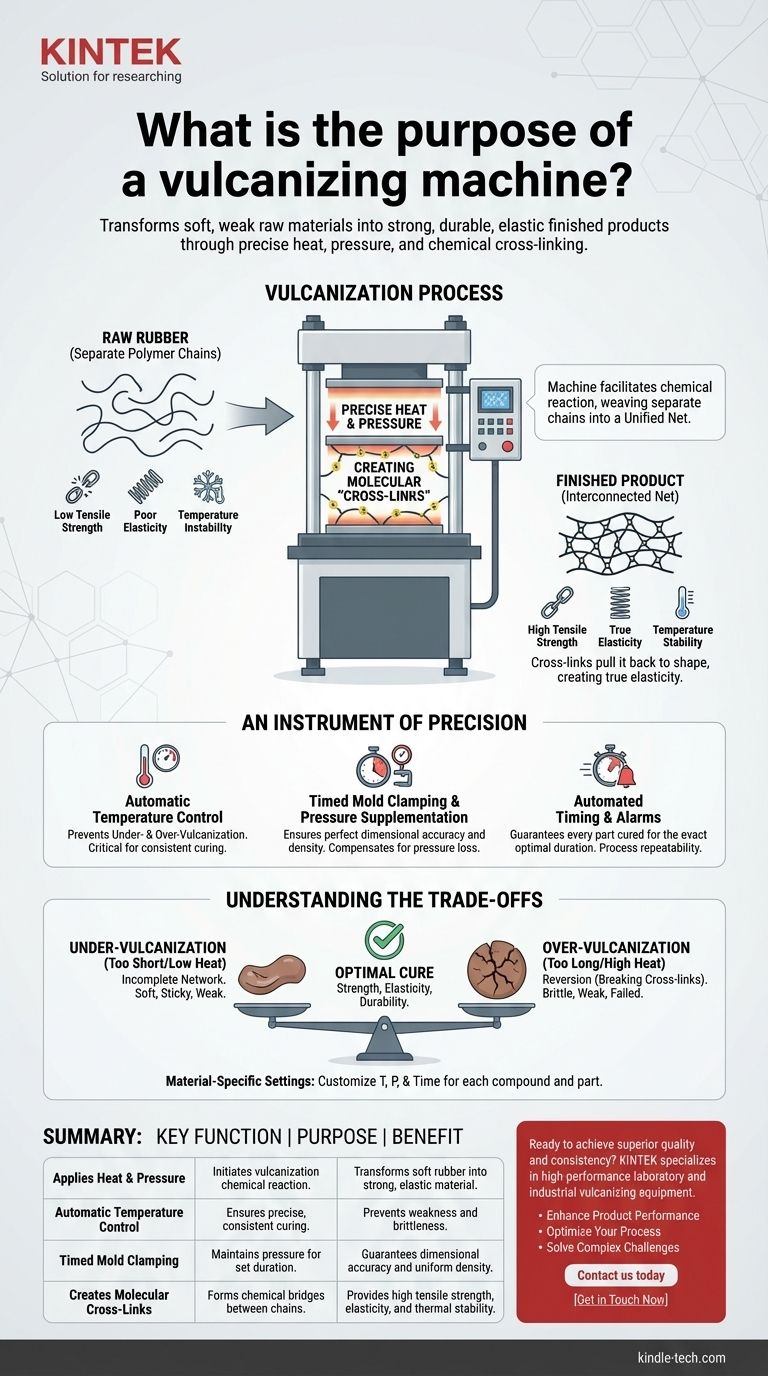

The Core Problem: Why Raw Rubber is Limited

Before vulcanization, natural or synthetic rubber exists as long, separate polymer chains. This molecular structure gives it several undesirable properties that limit its use in demanding applications.

Low Tensile Strength

In its raw state, rubber is weak and tears easily. The individual polymer chains are not bound to each other, allowing them to be pulled apart with little force.

Poor Elasticity

While raw rubber can be stretched, it does not reliably return to its original shape. This phenomenon, known as plastic deformation, makes it unsuitable for products that require memory and resilience, like seals or tires.

Temperature Instability

Uncured rubber is highly sensitive to temperature. It becomes sticky and soft when warm and turns hard and brittle when cold, making it unreliable in real-world operating conditions.

How Vulcanization Creates a High-Performance Material

The process of vulcanization, facilitated by the machine, directly solves these problems by altering the rubber's molecular structure.

Creating Molecular "Cross-Links"

The machine applies heat to initiate a chemical reaction. Typically, a curing agent like sulfur is mixed into the rubber beforehand. The heat causes the sulfur atoms to form strong cross-links, or chemical bridges, between the individual polymer chains.

From Separate Chains to a Unified Net

Think of raw rubber as a bowl of uncooked spaghetti strands that can slide past each other easily. Vulcanization is like weaving those strands into a single, interconnected net. When you stretch this net, the cross-links pull it back to its original shape, creating true elasticity.

The Role of Pressure and Molds

While heat drives the chemical reaction, the machine simultaneously applies immense pressure. This serves two functions: it forces the rubber to conform perfectly to the shape of the mold, and it ensures uniform heat distribution and density throughout the part.

The Vulcanizing Machine: An Instrument of Precision

The machine's features are designed to manage the vulcanization process with high precision. This control is what guarantees a consistent, high-quality final product.

Automatic Temperature Control

This is the most critical function. The temperature must be high enough to start the reaction but controlled to prevent over-vulcanization, which can make the rubber brittle.

Timed Mold Clamping and Pressure Supplementation

The machine clamps the mold shut and maintains a set pressure for a specific duration. Many machines feature automatic pressure supplementation to compensate for any minor pressure loss, ensuring the part's dimensional accuracy and density are perfect.

Automated Timing and Alarms

Vulcanization is a time-sensitive process. If the cycle is too short, the rubber is under-cured and weak. If it's too long, it becomes brittle. The machine's timer and alarms ensure that every part is cured for the exact optimal duration, enabling process repeatability.

Understanding the Trade-offs

Achieving optimal properties is a balancing act. The machine's precision is essential for navigating the fine line between a perfect cure and a failed part.

The Risk of Under-Vulcanization

Insufficient heat or time results in an incomplete network of cross-links. The final product will feel soft or sticky and will lack the required strength and elasticity.

The Danger of Over-Vulcanization (Reversion)

Conversely, too much heat or time can begin to break the newly formed cross-links. This process, known as reversion, ironically causes the rubber to lose its strength and elasticity, resulting in a failed part.

Material-Specific Settings

There is no universal setting. The optimal temperature, pressure, and time depend entirely on the specific rubber compound, the part's thickness, and the vulcanizing agents used. The machine's purpose is to allow operators to dial in and repeat these exact parameters.

Making the Right Choice for Your Goal

Understanding the machine's purpose helps clarify its role in achieving specific production outcomes.

- If your primary focus is consistent quality: The machine's core purpose is to provide a repeatable, automated process that eliminates variation between batches.

- If your primary focus is product performance: The purpose of vulcanization is to fundamentally enhance the rubber's strength, elasticity, and thermal stability.

- If your primary focus is complex part geometry: The machine's ability to apply high pressure within a mold is what allows you to form the raw material into a precise, finished shape during the curing cycle.

Ultimately, the vulcanizing machine is the essential tool that transforms a raw material's potential into engineered and reliable performance.

Summary Table:

| Key Function | Purpose | Benefit |

|---|---|---|

| Applies Heat & Pressure | Initiates the vulcanization chemical reaction. | Transforms soft rubber into a strong, elastic material. |

| Automatic Temperature Control | Ensures precise, consistent curing. | Prevents under-vulcanization (weakness) and over-vulcanization (brittleness). |

| Timed Mold Clamping | Maintains pressure for a set duration. | Guarantees dimensional accuracy and uniform density in the final part. |

| Creates Molecular Cross-Links | Forms chemical bridges between polymer chains. | Provides high tensile strength, elasticity, and temperature stability. |

Ready to achieve superior quality and consistency in your rubber or plastic production?

KINTEK specializes in high-performance laboratory and industrial equipment. Our expertise in vulcanizing technology can help you:

- Enhance Product Performance: Achieve the precise strength, elasticity, and durability your applications demand.

- Optimize Your Process: Leverage automated controls for repeatable, high-quality results batch after batch.

- Solve Complex Challenges: From intricate part geometries to specific material compounds, we provide solutions tailored to your needs.

Contact us today to discuss how our vulcanizing solutions can transform your manufacturing process.

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is multilayer blown film? Engineered Packaging for Superior Performance

- What are the disadvantages of single screw extruders? Key Limitations for Complex Materials

- What is the principle of calendering? Enhance Fabric Surface with Heat and Pressure

- What is a calendering machine? Transform Material Surfaces with Precision

- What are the different types of internal mixers? Choose Between Tangential & Intermeshing Rotors

- What is an electric mixer called? Hand Mixer vs. Stand Mixer Explained

- What are the advantages of a two-high rolling mill? Cost-Effective Durability for Heavy Reduction

- What is meant by two high rolling mill? A Guide to Core Material Processing