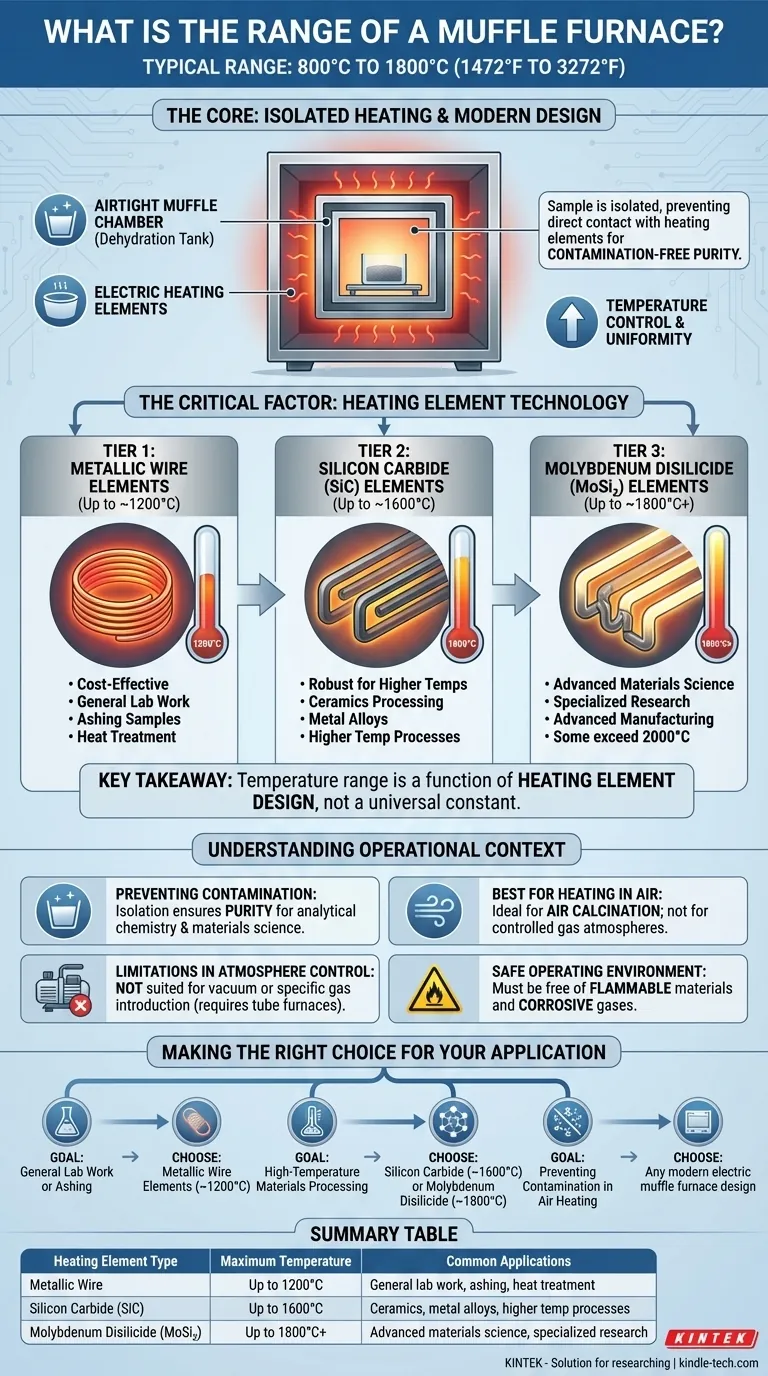

At its core, a muffle furnace typically operates within a temperature range of 800°C to 1800°C (1472°F to 3272°F). The specific maximum temperature a furnace can achieve is not a single standard but is directly determined by the materials used for its internal heating elements. This design allows for high-temperature processes like melting metals, ashing samples, and heat-treating materials in a controlled environment.

The key takeaway is that a muffle furnace's temperature range is a function of its design, not a universal constant. The choice between a 1200°C, 1600°C, or 1800°C model depends entirely on the technology of its heating elements and the specific application it's built for.

What Defines a Muffle Furnace?

The Isolated Heating Chamber

The defining feature of a muffle furnace is its design, which separates the material being heated from the heat source. The sample is placed inside an airtight chamber, often called the muffle or "dehydration tank."

This design prevents direct contact with the heating elements and, in older fuel-fired models, any byproducts of combustion.

Modern Electric Heating

Most modern muffle furnaces are electric. They use high-resistance heating elements to generate heat, which radiates into the muffle chamber. This electric design offers superior temperature control and uniformity while eliminating contamination from combustion.

The Critical Factor: Heating Element Technology

A furnace's maximum temperature is dictated by the physical limits of its heating elements. Different materials are used to achieve different temperature tiers.

Standard Metallic Wire Elements (Up to ~1200°C)

The most common and cost-effective muffle furnaces use metallic wire heating elements. These are suitable for a wide range of general-purpose lab work and heat treatment.

Silicon Carbide (SiC) Elements (Up to ~1600°C)

For applications requiring higher temperatures, such as working with certain ceramics or metal alloys, furnaces employ silicon carbide heating elements. These are more robust and can sustain significantly higher operational temperatures.

Molybdenum Disilicide (MoSi₂) Elements (Up to ~1800°C)

The highest tier of common muffle furnaces uses molybdenum disilicide elements. These are designed for specialized, high-temperature processes in materials science, research, and advanced manufacturing. Some highly specialized units can exceed 2000°C.

Understanding the Operational Context

Simply knowing the temperature range is not enough. The unique design of a muffle furnace brings specific advantages and limitations.

Preventing Sample Contamination

The primary advantage of the muffle design is purity. By isolating the sample, the furnace ensures that byproducts from the heat source do not contaminate the material. This is crucial in analytical chemistry and materials science.

Best for Heating in Air

A standard muffle furnace is designed for air calcination or heating in a normal atmospheric environment. It is the ideal choice for processes that don't require a specific controlled gas atmosphere.

Limitations in Atmosphere Control

Because of its design, a typical muffle furnace is not suited for processes that require a vacuum or the introduction of specific gases. Such applications require more specialized tube furnaces.

Safe Operating Environment

For safety and longevity, a muffle furnace must be operated in an environment free of flammable materials and corrosive gases. The high temperatures involved demand strict adherence to safety protocols.

Making the Right Choice for Your Application

To select the correct furnace, you must match its capabilities to your specific goal.

- If your primary focus is general lab work or ashing: A standard furnace with metallic wire elements reaching up to 1200°C is almost always the most practical and cost-effective solution.

- If your primary focus is high-temperature materials processing: You must select a furnace with silicon carbide (1600°C) or molybdenum disilicide (1800°C) elements to meet your requirements.

- If your primary focus is preventing contamination during heating in air: The fundamental design of any modern electric muffle furnace is perfectly suited for your needs.

Ultimately, understanding the link between heating element technology and maximum temperature empowers you to choose the right tool for the job.

Summary Table:

| Heating Element Type | Maximum Temperature | Common Applications |

|---|---|---|

| Metallic Wire | Up to 1200°C | General lab work, ashing, heat treatment |

| Silicon Carbide (SiC) | Up to 1600°C | Ceramics, metal alloys, higher temp processes |

| Molybdenum Disilicide (MoSi₂) | Up to 1800°C+ | Advanced materials science, specialized research |

Need the perfect muffle furnace for your specific temperature requirements? KINTEK specializes in laboratory equipment and consumables, offering a full range of muffle furnaces from standard 1200°C models to high-temperature 1800°C units. Our experts will help you select the ideal furnace based on your application needs, ensuring precise temperature control, contamination-free heating, and reliable performance. Contact our team today for a personalized consultation and get the right equipment for your lab's success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the materials used in a muffle furnace? A Guide to Durable Construction & Optimal Performance

- What is the difference between a hot air oven and a muffle furnace? Choose the Right Tool for Your Thermal Process

- What is the importance of muffle furnace in laboratory? Achieve Precise, Contaminant-Free Heating

- What are the safety precautions for a muffle furnace? A Guide to Preventing Burns, Fires, and Electrical Hazards

- What is the burnout cycle on a furnace? Stop This Destructive Overheating Pattern Now