In Chemical Vapor Deposition (CVD), the substrate is far more than a passive surface. It serves as the physical foundation and an active chemical participant where precursor gases react and solidify to form a thin film. The substrate's properties, including its material and temperature, directly control the quality, structure, and even the type of material that is grown.

The central role of the substrate in CVD is to actively guide the deposition process. It is not merely a stage for the reaction but a critical component that dictates the chemical pathways and the atomic arrangement of the final thin film.

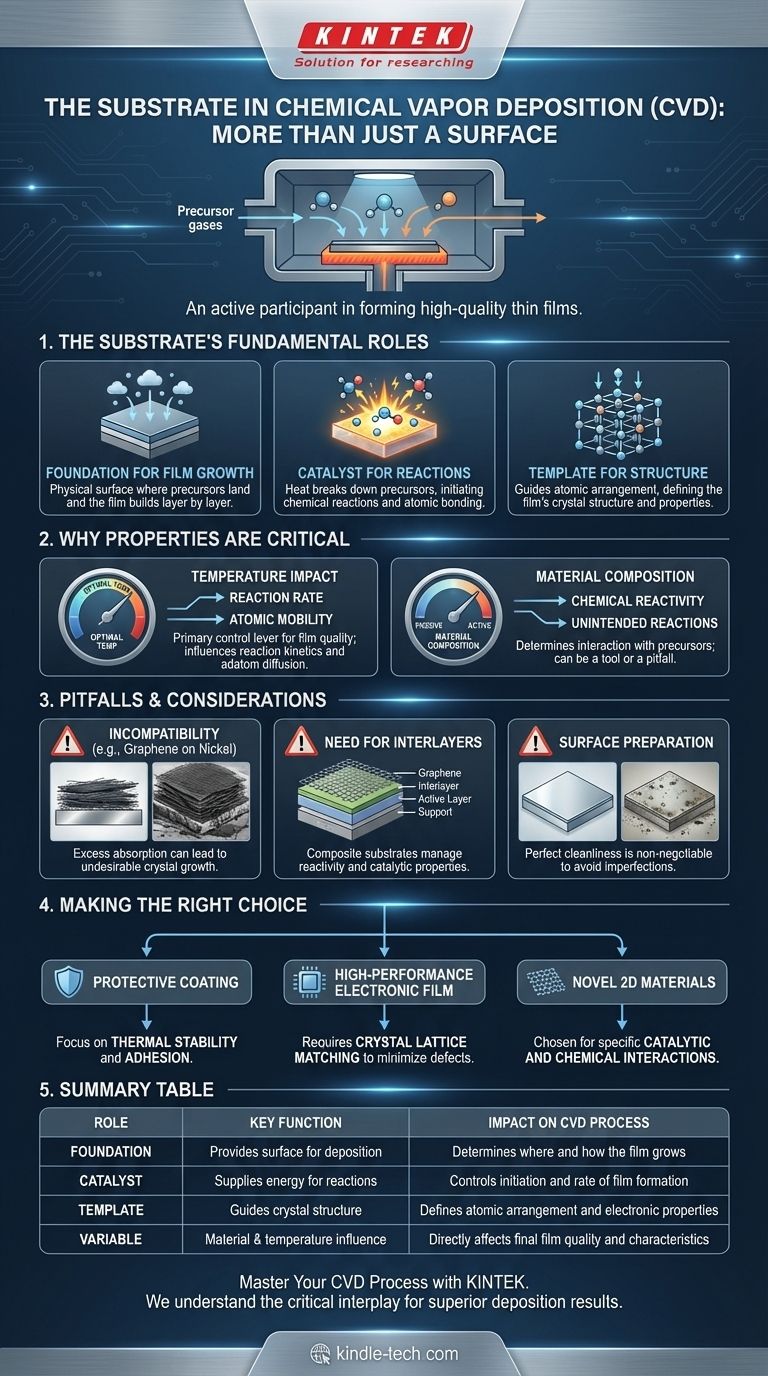

The Substrate's Fundamental Roles

The substrate performs several critical functions simultaneously during the CVD process. Understanding these roles is essential for controlling the outcome of the deposition.

The Foundation for Film Growth

The most basic role of the substrate is to provide a surface for the deposition to occur. Precursor gases are introduced into a vacuum chamber and are drawn toward the heated workpiece, which is the substrate.

The film builds up layer by layer directly on this surface, bonding to it over time.

A Catalyst for Chemical Reactions

The substrate surface is often where the critical chemical reactions happen. The heat from the substrate provides the energy needed to break down the volatile precursor gases.

This breakdown releases the desired atoms, which then bond to the substrate, initiating the growth of the thin film. In this way, the substrate acts as a catalyst for the entire process.

A Template for Crystal Structure

For many advanced materials, the atomic arrangement of the substrate's surface acts as a template for the growing film.

The deposited atoms will often align with the substrate's crystal lattice, creating a highly ordered film with specific properties. This is crucial in applications like semiconductor manufacturing.

Why Substrate Properties Are Critical

The choice of substrate material and the control of its temperature are two of the most important variables in any CVD process. They have a direct and profound impact on the final product.

The Impact of Temperature

The substrate's temperature is a primary control lever for the quality of the deposited film. It influences the reaction rate of the precursors and how mobile atoms are once they land on the surface.

Optimizing this temperature is necessary to achieve the desired film properties, and in some cases, specific cooling steps may be required.

The Influence of Material Composition

The substrate material can actively participate in the chemical reaction, sometimes in unintended ways. Its composition determines its chemical reactivity with the precursor gases.

This interaction is a powerful tool but also a potential pitfall if not properly understood and controlled.

Common Pitfalls and Considerations

Choosing the wrong substrate or failing to control its conditions can lead to process failure. The interaction between the substrate and the precursor chemistry is a delicate balance.

Substrate-Precursor Incompatibility

A classic example is the growth of graphene using a nickel substrate. If the nickel substrate is too thick, it can absorb large amounts of carbon from the precursor gas.

This absorption leads to the formation of thick, undesirable graphite crystals instead of the intended single layer of graphene. The substrate's properties changed the final product entirely.

The Need for Interlayers

To solve problems like the nickel-graphene issue, engineers often use an interlayer. For instance, evaporating a thin nickel film onto a silicon dioxide (SiO2) support surface.

This creates a composite substrate that has the catalytic properties of nickel but limits its capacity to absorb carbon, allowing for proper graphene growth.

Surface Preparation is Non-Negotiable

The substrate surface must be perfectly clean and free of defects before the CVD process begins.

Any contaminants, dust, or oils on the surface will disrupt the film growth, leading to imperfections, poor adhesion, and failure of the final device or coating.

Making the Right Choice for Your Goal

The ideal substrate is entirely dependent on the desired outcome of the CVD process. Your goal dictates your choice.

- If your primary focus is a simple protective coating: Substrate choice is mainly about thermal stability and ensuring strong adhesion of the film.

- If your primary focus is a high-performance electronic film: You need a substrate with a crystal lattice that closely matches your film to minimize defects and strain.

- If your primary focus is synthesizing novel 2D materials: The substrate must be chosen for its specific catalytic and chemical interactions with the precursor gases.

Ultimately, viewing the substrate as the foundational blueprint for your film—rather than just a carrier—is the key to mastering the CVD process.

Summary Table:

| Substrate Role | Key Function | Impact on CVD Process |

|---|---|---|

| Foundation | Provides a surface for deposition | Determines where and how the film grows |

| Catalyst | Supplies energy for precursor reactions | Controls the initiation and rate of film formation |

| Template | Guides the crystal structure of the film | Defines the atomic arrangement and electronic properties |

| Variable | Material composition and temperature | Directly influences final film quality and characteristics |

Master Your CVD Process with the Right Substrate

The substrate is the blueprint for your thin film's success. Choosing the wrong material or mishandling its conditions can lead to failed depositions and costly setbacks. KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories like yours.

Our experts understand the critical interplay between substrate, precursor, and process parameters. We provide the tools and support to ensure your substrates are perfectly prepared and your CVD runs yield high-quality, high-performance films every time.

Let KINTEK help you build from the foundation up. Contact our team today to discuss your specific application and achieve superior deposition results.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures