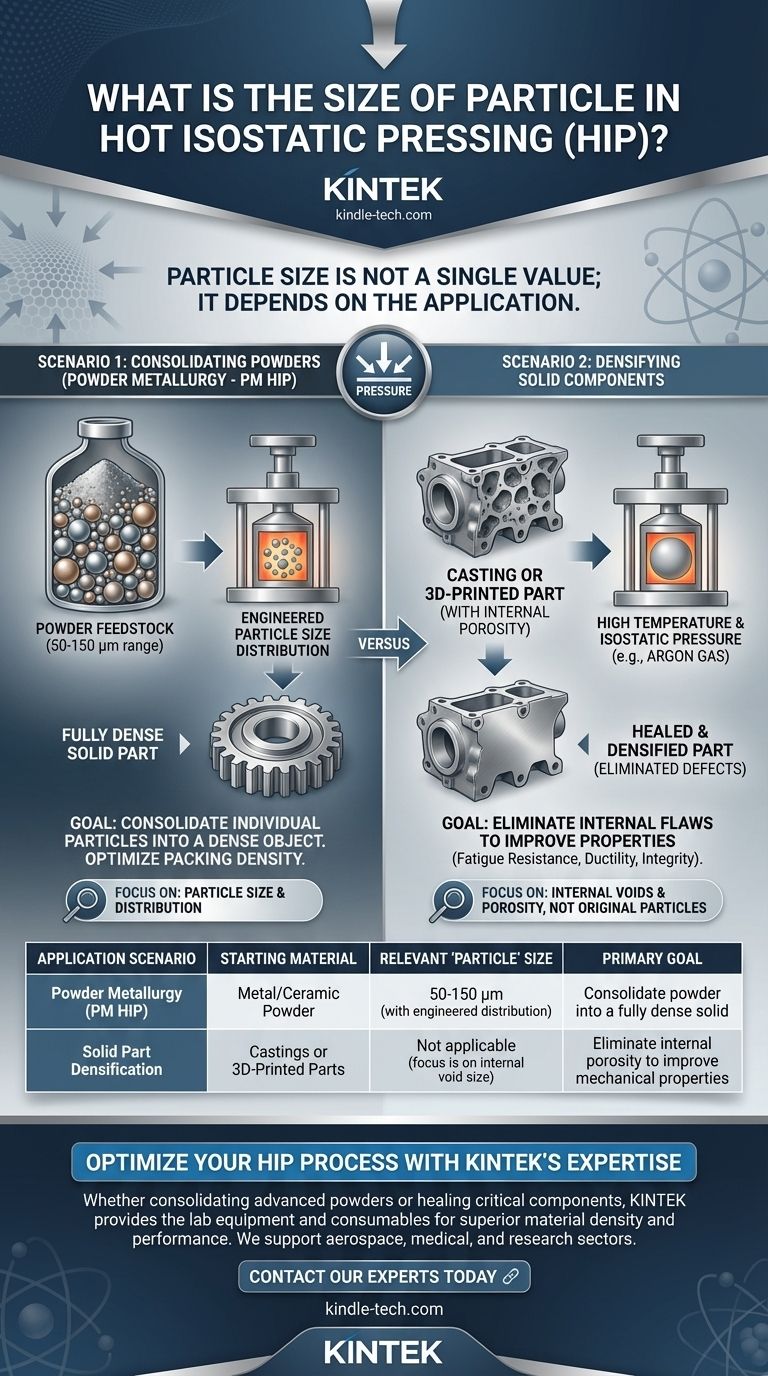

The particle size for hot isostatic pressing (HIP) is not a single value; it is entirely dependent on the application. For processes starting with metal or ceramic powders, a typical range might be 50 to 150 micrometers, but the key is using a specific distribution of sizes to ensure high packing density. However, HIP is also frequently used to densify solid parts like castings or 3D-printed components, where the concept of initial particle size is not the primary concern.

The critical insight is that Hot Isostatic Pressing (HIP) is a consolidation and densification process, not a forming process. Therefore, the relevant "particle" question depends entirely on whether you are starting with a container of loose powder or a pre-formed solid component with internal voids.

The Dual Role of Hot Isostatic Pressing

The user's question presupposes that HIP always starts with a powder. In reality, the process has two common but distinct applications that fundamentally change how we think about the starting material.

Scenario 1: Consolidating Powders (Powder Metallurgy)

When creating a part from scratch using powder, the process is known as Powder Metallurgy HIP (PM HIP).

In this context, loose metal or ceramic powder is sealed in a canister or mold shaped like the final part. The goal is to consolidate these individual particles into a fully dense, solid object.

The size and distribution of the powder particles are critical. A carefully engineered mix of finer and coarser particles is often used to maximize the initial "tap density," minimizing the empty space between them before the HIP cycle even begins.

Scenario 2: Densifying Solid Components

The other major application of HIP is to eliminate internal porosity in already-formed parts.

This is common for components produced through casting or additive manufacturing (3D printing). These processes can leave behind microscopic voids or poor layer adhesion, which act as stress concentrators and potential failure points.

In this scenario, the part is already a solid, near-net-shape object. The HIP process applies high temperature and isostatic pressure to essentially "squeeze" these internal defects closed, creating a uniform and fully dense microstructure. The focus is on the voids, not the original particles that formed the part.

Why the Starting Form Matters

Understanding your starting material—powder or solid—is the most important factor in a successful HIP application. The objectives of the process are different for each.

The Goal for Powders: Building from Scratch

For PM HIP, you are fundamentally building a new solid. The process must weld every single particle to its neighbors.

Incorrect particle size distribution can lead to low initial packing density, requiring more significant material movement during the HIP cycle and potentially leaving residual porosity.

The Goal for Solids: Healing Internal Flaws

For solid part densification, you are improving an existing object. The material is already consolidated, but it contains imperfections.

The process targets these flaws, as noted in the references, to improve properties like fatigue resistance, ductility, and overall part integrity. The pressure medium—typically an inert gas like argon—acts uniformly on all surfaces to collapse the internal voids.

Common Misconceptions to Avoid

Clarity on the role of HIP prevents costly errors in process selection and material specification.

Misconception: HIP is only for powders.

A massive application of HIP, particularly in the aerospace and medical industries, is for densifying investment castings. This "healing" process is what allows cast components to achieve the reliability of wrought or forged materials.

Misconception: Any high-quality powder will work.

For PM HIP, even a high-purity powder is insufficient if the particle size distribution is wrong. Achieving a high packing density is a science in itself and is a prerequisite for a successful outcome.

How to Apply This to Your Project

Your approach should be dictated by your end goal and your starting material.

- If your primary focus is creating a fully dense component from raw powder: You must engineer the particle size distribution to maximize the initial packing density before the HIP cycle.

- If your primary focus is enhancing the mechanical properties of a cast or 3D-printed part: Your concern is the size and distribution of internal voids within the existing component, not the original particle feedstock.

Ultimately, understanding whether you are building a part or healing one is the key to correctly applying the power of hot isostatic pressing.

Summary Table:

| Application Scenario | Starting Material | Relevant 'Particle' Size | Primary Goal |

|---|---|---|---|

| Powder Metallurgy (PM HIP) | Metal/Ceramic Powder | 50-150 μm (with engineered distribution) | Consolidate powder into a fully dense solid |

| Solid Part Densification | Castings or 3D-Printed Parts | Not applicable (focus is on internal void size) | Eliminate internal porosity to improve mechanical properties |

Optimize Your HIP Process with KINTEK's Expertise

Whether you are consolidating advanced powders or healing critical components from casting and additive manufacturing, the right approach to material preparation is essential for success. KINTEK specializes in providing the lab equipment and consumables necessary to support your hot isostatic pressing applications.

We help our customers in the aerospace, medical, and research sectors achieve superior material density and performance. Let us assist you in selecting the right tools and materials for your specific HIP needs.

Contact our experts today to discuss how we can enhance your HIP process and ensure optimal results for your laboratory.

Visual Guide

Related Products

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the role of a hot pressing system in TlBr detector production? Enhance Crystal Density & Detector Efficiency

- What role does axial pressure play during vacuum hot pressing of Lithium Niobate? Optimize Density & Grain Size

- How do graphite molds function within the vacuum hot pressing process for ZnS? Optimize Densification & Optical Clarity

- What is direct current sintering? A Faster, More Efficient Way to Densify Materials

- What role does a vacuum hot pressing furnace play in Ti-6Al-7Nb production? Achieve 99%+ Density and Pure Microstructure

- How does the precise temperature control of a Vacuum Hot Press affect AZ31/UCF/AZ31 composites? Optimize Bonding

- How does a vacuum hot press furnace improve the density of Ti2AlN ceramics? Achieve 98.5%+ Density & Superior Strength

- How is heating achieved in an SPS furnace for non-conductive LLZO? Master Indirect Joule Heating Techniques