At its core, sputtering is a physical process used to deposit exceptionally thin and uniform layers of material onto a surface. It works by creating a plasma in a vacuum and using the ions from that plasma to bombard a source material, known as a target. This bombardment physically knocks atoms loose from the target, which then travel and coat a nearby object, called a substrate, forming a precise thin film.

Sputtering is not a chemical reaction or a melting process. Think of it as a microscopic game of billiards: high-energy ions act as cue balls, striking atoms in a target material and ejecting them with enough force to travel across a vacuum chamber and stick to a substrate.

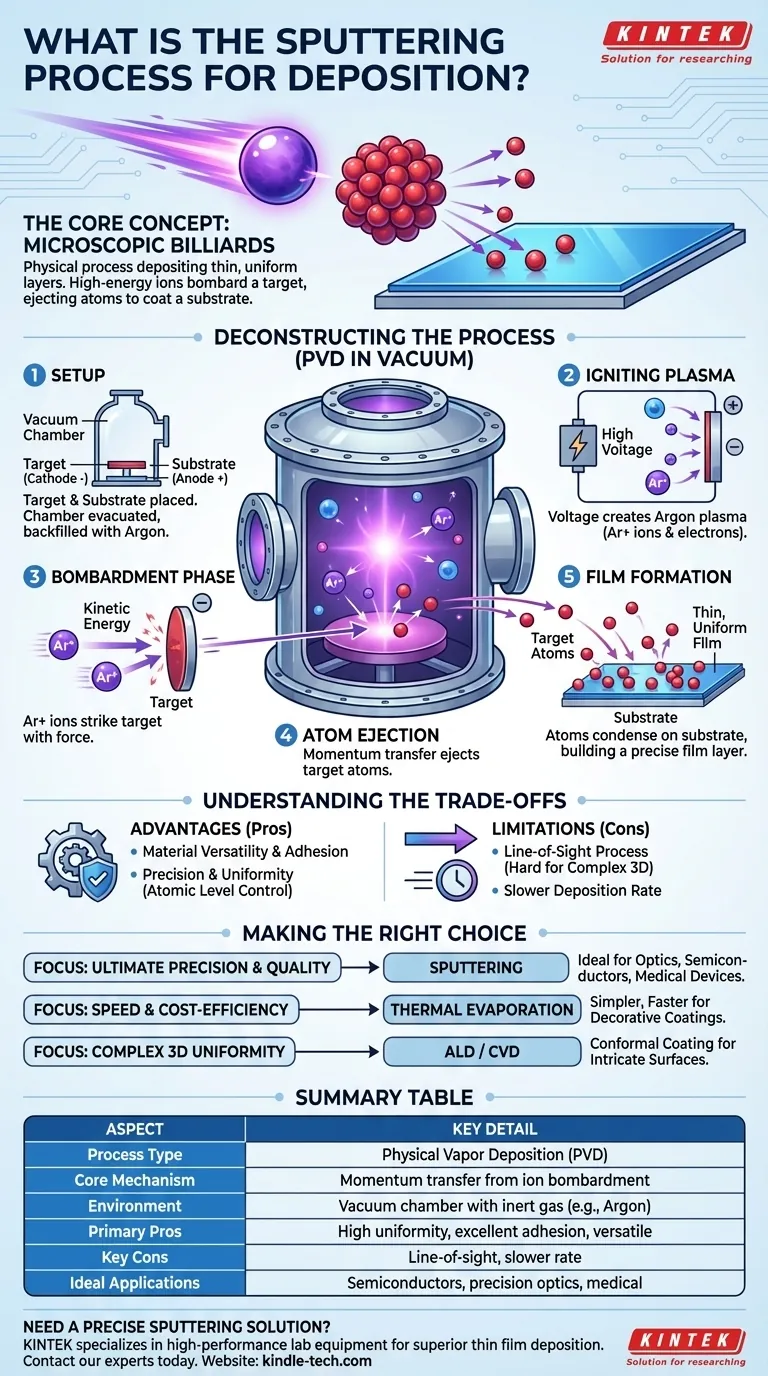

Deconstructing the Sputtering Process

Sputtering is a type of Physical Vapor Deposition (PVD). To understand its value, we must break down the mechanics of the process, which occur within a highly controlled vacuum environment.

### The Essential Setup: Chamber and Components

The process begins by placing two key items into a vacuum chamber: the target and the substrate. The target is a solid block of the material you wish to deposit, while the substrate is the object you want to coat.

The chamber is pumped down to a near-perfect vacuum and then backfilled with a small amount of a high-purity inert gas, most commonly Argon.

### Igniting the Plasma

A powerful voltage is applied between the target and the chamber, making the target a negatively charged cathode. This strong electric field energizes the Argon gas, stripping electrons from the Argon atoms.

This creates a plasma, an ionized gas consisting of positively charged Argon ions (Ar+) and free electrons, which typically glows purple or blue.

### The Bombardment Phase

The positively charged Argon ions within the plasma are now powerfully attracted and accelerated toward the negatively charged target.

They strike the target's surface with significant kinetic energy. This is the "sputtering" event—a momentum transfer that is purely physical.

### From Target to Substrate

The energy from the ion impact is sufficient to overcome the binding energy holding the target's surface atoms in place. This sets off a collision cascade within the material.

When this cascade reaches the surface, atoms of the target material are ejected, or "sputtered," into the vacuum chamber. These atoms travel in a vapor stream toward the substrate.

### Film Formation on the Substrate

The ejected target atoms land on the substrate, where they cool, condense, and bond to the surface.

Over time, these atoms build up layer by layer, forming a thin, solid, and highly uniform film. The process allows for precise control over the film's thickness, density, and grain structure.

Understanding the Trade-offs

Sputtering is a powerful technique, but its advantages come with specific limitations. Understanding these trade-offs is crucial for deciding if it is the right process for your application.

### Advantage: Material Versatility and Adhesion

Sputtering can be used to deposit a vast range of materials, including pure metals, alloys, and even insulating ceramic compounds (using a variant called RF sputtering). The high energy of the deposited atoms often results in excellent film adhesion.

### Advantage: Precision and Uniformity

The primary strength of sputtering is its control. By carefully managing gas pressure, voltage, and time, you can achieve films with highly specific thicknesses (down to single angstroms) and uniform properties, which is critical for optical and semiconductor applications.

### Limitation: It's a Line-of-Sight Process

Sputtered atoms travel in a relatively straight line from the target to the substrate. This makes it challenging to uniformly coat complex, three-dimensional objects with hidden surfaces or deep trenches. Substrate rotation is often required to mitigate this.

### Limitation: Deposition Rate

Compared to some other methods like thermal evaporation, sputtering can be a slower process. This is the trade-off for achieving higher-quality, denser, and more uniform films. The need for precise control often prioritizes quality over speed.

Making the Right Choice for Your Goal

Sputtering is one of several deposition techniques, and its suitability depends entirely on your end goal.

- If your primary focus is ultimate precision and film quality: Sputtering offers unmatched control over film thickness, density, and structure, making it ideal for high-performance optics, semiconductors, and medical devices.

- If your primary focus is speed and cost-efficiency for simple coatings: Thermal evaporation is often a faster and simpler alternative for applications like decorative metal coatings on plastics.

- If your primary focus is coating complex 3D objects uniformly: Techniques like Atomic Layer Deposition (ALD) or Chemical Vapor Deposition (CVD) are often superior due to their ability to conformally coat intricate surfaces.

Understanding the fundamental mechanism of sputtering empowers you to select the most effective tool for your specific engineering challenge.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Momentum transfer from ion bombardment |

| Typical Environment | Vacuum chamber with inert gas (e.g., Argon) |

| Primary Advantages | High uniformity, excellent adhesion, material versatility |

| Key Limitations | Line-of-sight process, slower deposition rate |

| Ideal Applications | Semiconductors, precision optics, medical coatings |

Need a precise and reliable sputtering solution for your lab?

KINTEK specializes in high-performance lab equipment, including sputtering systems designed for superior thin film deposition. Whether you're working in semiconductor research, optical coating development, or medical device manufacturing, our expertise ensures you get the precision, uniformity, and material versatility your projects demand.

Contact our experts today to discuss how KINTEK's sputtering equipment can enhance your laboratory's capabilities and help you achieve your specific coating goals.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the components of a pyrolysis reactor? A Guide to Core Parts & Designs

- Is a carbon brush a good conductor of electricity? The Surprising Engineering Choice

- What thickness is magnetron sputtering for coating? Achieve Precise, Functional Thin Films

- What does a sputter coater do? Achieve Ultra-Thin, Uniform Coatings for Your Lab

- What temperature is maintained in a bacterial incubator? The 37°C Standard Explained

- What is the necessity of using a laboratory drying oven for Mo-Ti-N catalysts? Protect Your Porous Architecture

- How do magnets enhance the sputtering rate in magnetron sputtering process and improve the thin film quality? Boost Deposition Speed & Film Quality

- What is the temperature stability of graphite? Unlocking Extreme Heat Resistance in the Right Environment