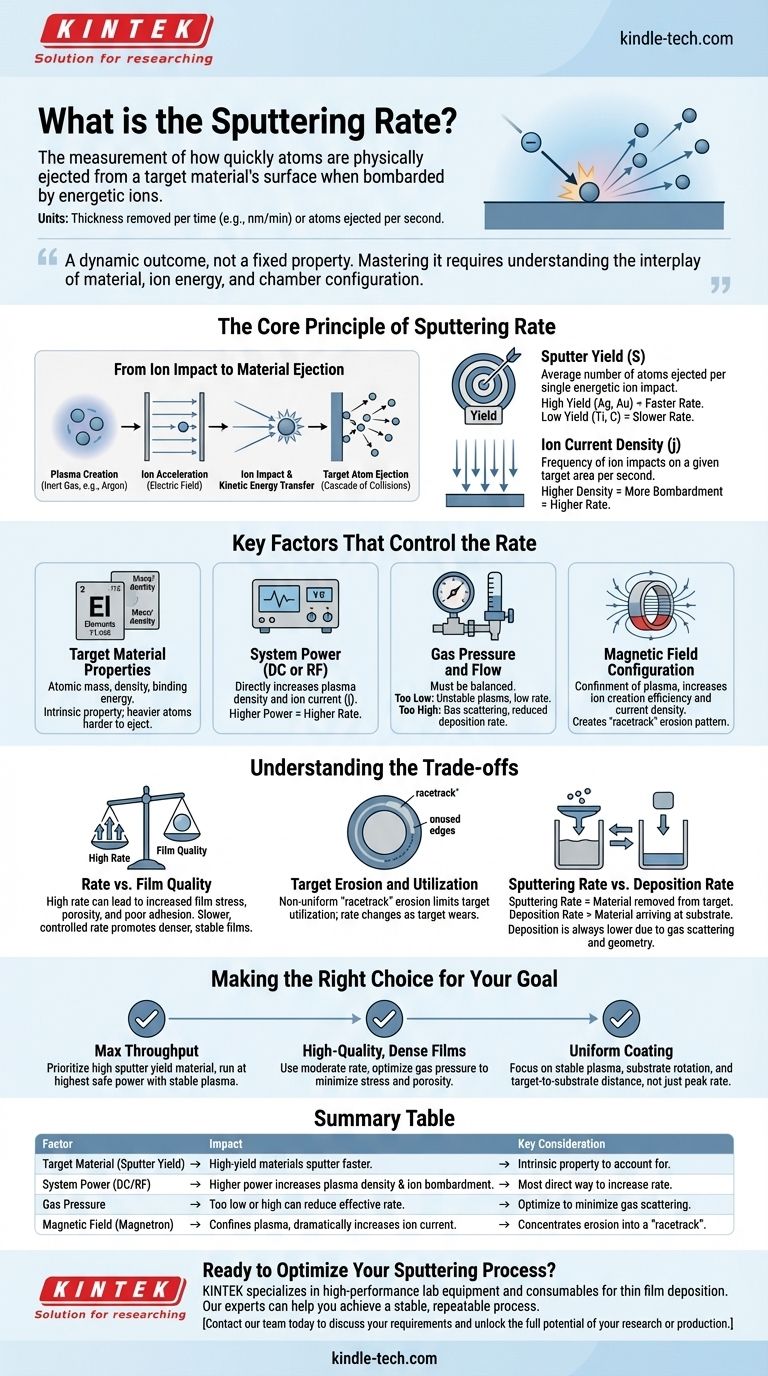

In simple terms, the sputtering rate is a measurement of how quickly atoms are physically ejected from a target material's surface when it is bombarded by energetic ions. It is most often expressed as the thickness of material removed from the target per unit of time (e.g., nanometers per minute) or as the number of atoms ejected per second. This rate is the fundamental driver of the deposition process used to create thin films.

The sputtering rate is not a fixed property of a material but a dynamic outcome of your system's parameters. Mastering it requires understanding the interplay between the target material, the energy of the ion bombardment, and the specific configuration of your sputtering chamber.

The Core Principle of Sputtering Rate

To control the sputtering rate, you must first understand the fundamental physics at play. The process is a chain of events, and each link in that chain is a variable you can often adjust.

From Ion Impact to Material Ejection

The entire process begins by creating a plasma from an inert gas, typically Argon. An electric field accelerates these positive Argon ions toward the negatively charged target. When an ion strikes the target, it transfers its kinetic energy, causing a cascade of collisions that results in the ejection of one or more target atoms.

The Sputter Yield (S)

Sputter Yield is the most important intrinsic property in this process. It is defined as the average number of target atoms ejected for each single energetic ion that strikes the surface. A material with a high sputter yield (like silver or gold) will sputter much faster than a material with a low yield (like titanium or carbon) under the same conditions.

The Role of Ion Current Density (j)

While sputter yield tells you the efficiency of each ion impact, the ion current density tells you the frequency of those impacts. It represents the number of ions striking a given area of the target per second. A higher ion current density means more bombardment and, therefore, a higher sputtering rate.

Key Factors That Control the Rate

The sputtering rate is a direct result of several adjustable system parameters. Understanding these levers is key to achieving a repeatable and optimized process.

Target Material Properties

The material's atomic mass, density, and binding energy directly influence its sputter yield. You cannot change these properties, but you must account for them. Heavier target atoms are generally harder to eject, lowering the rate.

System Power (DC or RF)

Increasing the power to the magnetron cathode is the most direct way to increase the sputtering rate. Higher power increases the density of the plasma, which in turn increases the ion current density (j) bombarding the target.

Gas Pressure and Flow

The pressure of the sputtering gas (e.g., Argon) must be carefully balanced.

- Too low: The plasma may be unstable or too sparse, resulting in a low ion current and a slow rate.

- Too high: The plasma is dense, but the sputtered atoms are more likely to collide with gas atoms on their way to the substrate. This "gas scattering" reduces the deposition rate, even if the sputtering rate at the target is high.

Magnetic Field Configuration

In magnetron sputtering, a magnetic field is used to trap electrons near the target surface. This dramatically increases the efficiency of ion creation, leading to a much higher ion current density and a significantly faster sputtering rate compared to non-magnetron systems. The strength and shape of this field are critical design parameters.

Understanding the Trade-offs

Simply maximizing the sputtering rate is rarely the goal. Pushing the rate too high often leads to compromises in film quality and process stability.

Rate vs. Film Quality

A very high sputtering rate means atoms arrive at the substrate with more energy and in greater numbers. This can increase film stress, create a more porous microstructure, and lead to poor adhesion. A slower, more controlled deposition often allows atoms to arrange themselves into a denser, more stable film structure.

Target Erosion and Utilization

The magnetic field that enhances the sputtering rate also concentrates it into a specific "racetrack" on the target's surface. This non-uniform erosion means the rate changes as the target wears down. It also limits target utilization, as much of the material outside the racetrack is left unsputtered.

Sputtering Rate vs. Deposition Rate

It is crucial to distinguish between these two terms.

- Sputtering Rate: Material being removed from the target.

- Deposition Rate: Material arriving at the substrate.

The deposition rate will always be lower than the sputtering rate due to gas scattering and geometric factors (i.e., not all sputtered atoms travel toward the substrate).

Making the Right Choice for Your Goal

Your ideal sputtering rate depends entirely on what you are trying to achieve with your thin film.

- If your primary focus is maximum throughput: Prioritize a high sputter yield material and run at the highest power your system and target can safely handle while maintaining plasma stability.

- If your primary focus is high-quality, dense films: Use a moderate sputtering rate and carefully optimize gas pressure to minimize film stress and porosity.

- If your primary focus is uniform coating over a large area: Focus less on the peak rate and more on stable plasma, substrate rotation, and optimizing the target-to-substrate distance to ensure even material distribution.

Ultimately, controlling the sputtering rate is about achieving a stable, repeatable process that produces the film properties you need.

Summary Table:

| Factor | Impact on Sputtering Rate | Key Consideration |

|---|---|---|

| Target Material (Sputter Yield) | High-yield materials (e.g., Ag, Au) sputter faster. | An intrinsic property you must account for. |

| System Power (DC/RF) | Higher power increases plasma density and ion bombardment. | The most direct way to increase the rate. |

| Gas Pressure | Must be balanced; too low or too high can reduce the effective rate. | Optimize to minimize gas scattering of sputtered atoms. |

| Magnetic Field (Magnetron) | Confines plasma, dramatically increasing ion current and rate. | Concentrates erosion into a "racetrack" on the target. |

Ready to Optimize Your Sputtering Process? Achieving the perfect balance between a high sputtering rate and superior film quality requires the right equipment and expertise. KINTEK specializes in high-performance lab equipment and consumables for all your thin film deposition needs. Our experts can help you select the ideal sputtering system to achieve a stable, repeatable process for your specific application.

Contact our team today to discuss your requirements and unlock the full potential of your research or production.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition