The primary strength of sintering is its ability to create strong, dense parts from powdered materials without having to melt them. This unique process uses heat and pressure to force individual particles to bond together on an atomic level, resulting in a solid mass with significantly enhanced mechanical properties, such as hardness and durability.

Sintering's core value lies not just in strengthening a material, but in making it possible to manufacture robust components from high-performance materials—like ceramics and refractory metals—that are incredibly difficult or energy-intensive to process using traditional melting and casting methods.

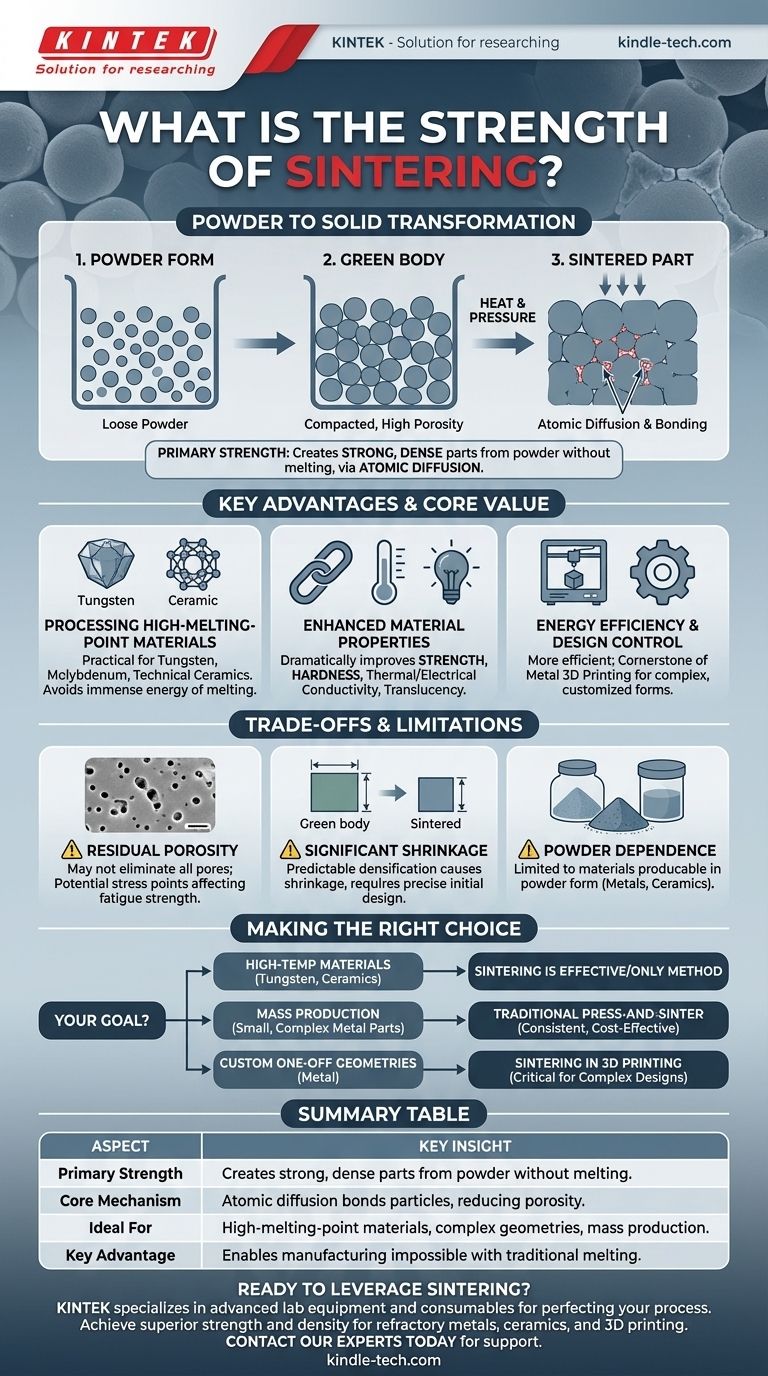

How Sintering Achieves Strength: The Transformation from Powder to Solid

Sintering is fundamentally a process of consolidation. It takes a loosely compacted powder and transforms it into a near-fully dense object by eliminating the empty spaces, or pores, between the particles.

The Starting Point: A Compacted "Green Body"

The process begins with a material in powder form, which is pressed or formed into the desired shape. This initial, fragile component is known as a "green body" and has a high degree of porosity.

The Role of Heat: Atomic Diffusion

The green body is then heated in a controlled furnace to a temperature below its melting point. At these high temperatures, the atoms at the contact points between particles become highly active and begin to diffuse across the particle boundaries.

The Result: Reduced Porosity and Increased Density

This atomic diffusion effectively builds "necks" or bridges between adjacent particles. As these necks grow, they pull the particle centers closer together, systematically eliminating the pores and causing the entire part to shrink and densify into a hard, strong, and durable final product.

Key Advantages of the Sintering Process

While enhanced strength is a primary outcome, the reasons for choosing sintering are often tied to its other unique capabilities.

Processing High-Melting-Point Materials

Sintering is often the only practical way to form parts from materials with extremely high melting points, such as tungsten, molybdenum, and many technical ceramics. Melting these materials would require immense energy and specialized equipment.

Enhanced Material Properties

By reducing porosity, sintering dramatically improves a material's physical characteristics. This includes not only strength and hardness but also enhanced thermal conductivity, electrical conductivity, and even translucency in certain ceramics.

Energy Efficiency and Design Control

Because it avoids the energy-intensive melting phase, sintering is a more efficient process. It is also a cornerstone of modern manufacturing methods like metal 3D printing, where it is used to fuse metal powder layer by layer, enabling the creation of highly complex and customized forms.

Understanding the Trade-offs and Limitations

No process is perfect. To use sintering effectively, it's crucial to understand its inherent constraints.

The Challenge of Residual Porosity

While sintering significantly reduces porosity, it may not eliminate it completely. Any remaining microscopic pores can act as stress concentration points, potentially impacting the material's ultimate fatigue strength compared to a fully wrought or cast equivalent.

Predictable but Significant Shrinkage

The densification process that gives a sintered part its strength also causes it to shrink. This shrinkage is predictable and must be precisely accounted for in the initial design of the green body to achieve the correct final dimensions.

Dependence on Powdered Materials

The most obvious limitation is that the process is only applicable to materials that can be produced in a powder form, primarily metals and ceramics.

Making the Right Choice for Your Goal

Selecting sintering depends entirely on your material, geometry, and production requirements.

- If your primary focus is high-temperature materials like tungsten or ceramics: Sintering is often the most effective—and sometimes the only—viable method for creating dense parts.

- If your primary focus is mass production of small, complex metal parts: Traditional press-and-sinter powder metallurgy offers excellent consistency, minimal waste, and cost-effective production at scale.

- If your primary focus is creating custom, one-off metal geometries: Sintering is the critical final step in most metal additive manufacturing (3D printing) processes that enables complex designs.

Ultimately, understanding the principles of sintering empowers you to leverage its unique strengths for materials and applications that are beyond the reach of conventional manufacturing.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Primary Strength | Creates strong, dense parts from powdered materials without melting. |

| Core Mechanism | Atomic diffusion bonds particles, reducing porosity and increasing density. |

| Ideal For | High-melting-point materials (tungsten, ceramics), complex geometries, mass production. |

| Key Advantage | Enables manufacturing of components impossible with traditional melting methods. |

Ready to leverage sintering for your high-performance materials?

KINTEK specializes in providing the advanced lab equipment and consumables needed to perfect your sintering process. Whether you are working with refractory metals, technical ceramics, or complex metal 3D printing, our solutions help you achieve superior part strength and density.

Contact our experts today to discuss how we can support your laboratory's specific sintering challenges and goals.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- How do high-temperature electric furnaces contribute to the homogenization of glass samples? Achieving Total Uniformity

- What is the difference between sintering and vitrification? Key Thermal Process Distinctions

- What are the applications of muffle furnaces? Essential Tools for High-Temperature Processes

- How does a muffle furnace with a PID controller impact doped zinc oxide nanoparticles? Precise Synthesis Control

- What does debinding do? Unlock the Key to Successful Metal and Ceramic Part Manufacturing

- What are muffle furnaces used for? Achieve Precise, Contaminant-Free High-Temperature Processing

- What role does a high-temperature muffle furnace play in the final formation of LLZO solid-state electrolytes?

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing