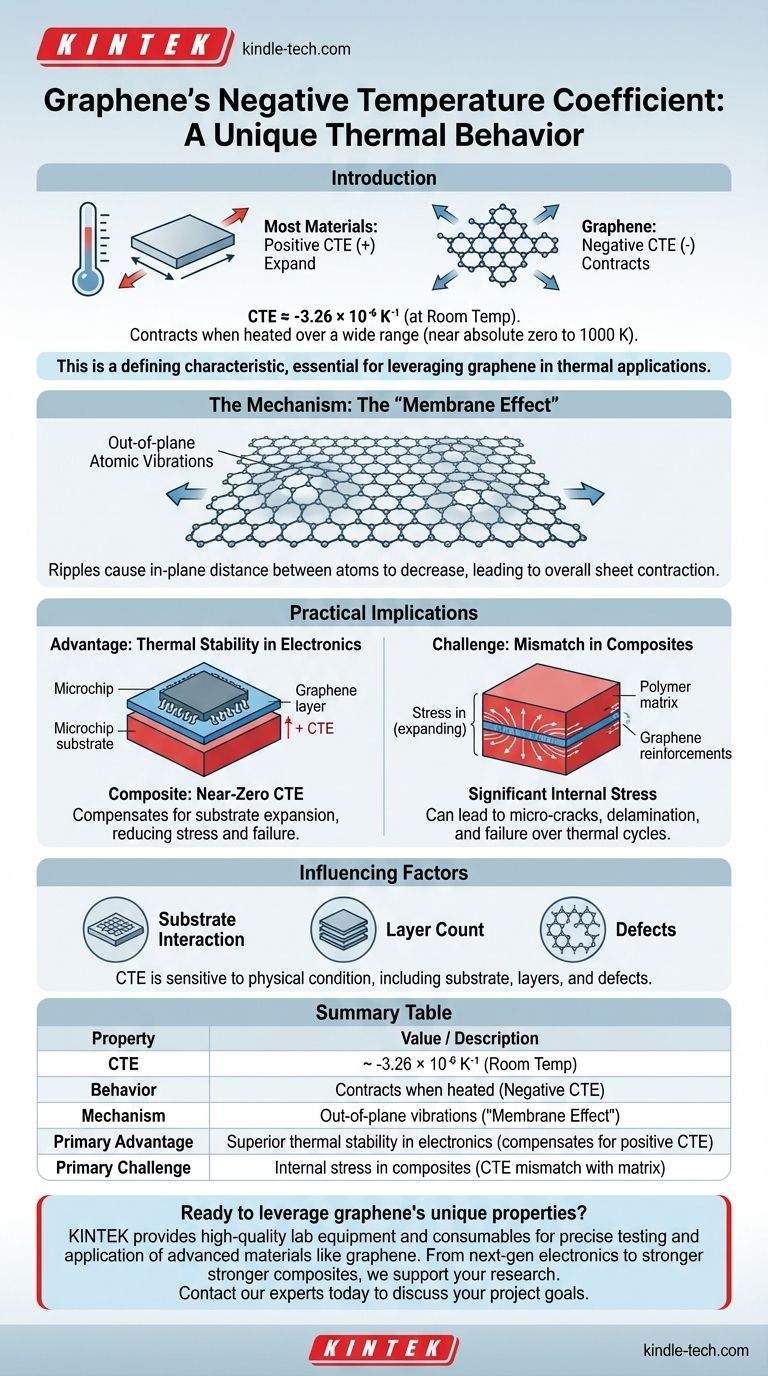

At room temperature, graphene has a negative temperature coefficient of thermal expansion (CTE) of approximately -3.26 × 10⁻⁶ K⁻¹. This means that, unlike most materials which expand when heated, graphene actually contracts. This unusual property holds true over a wide temperature range, from near absolute zero up to 1000 K (about 727 °C).

The most critical takeaway is that graphene’s negative thermal expansion is not a minor anomaly; it is a defining characteristic. Understanding this counter-intuitive behavior—shrinking upon heating—is essential for leveraging graphene in any thermal application.

What a Negative Temperature Coefficient Means

Defining Thermal Expansion

The coefficient of thermal expansion (CTE) measures how much a material's size changes with a change in temperature. Most materials have a positive CTE, meaning they expand when heated and contract when cooled.

This behavior is predictable and is a fundamental consideration in engineering, from building bridges to designing microchips.

Graphene's Unique Contraction

Graphene defies this common principle. Its negative CTE indicates that the material shrinks as its temperature increases.

This phenomenon is not exclusive to graphene but is characteristic of many 2D materials. It stems directly from its unique, one-atom-thick structure.

The Mechanism: The "Membrane Effect"

The reason for this contraction lies in atomic vibrations. When graphene is heated, its carbon atoms vibrate with increased energy.

Because it is a flexible 2D sheet, the dominant vibrations are out-of-plane, like the rippling of a drum skin. To accommodate these growing ripples, the in-plane distance between the atoms must decrease, causing the entire sheet to contract.

Practical Implications and Trade-offs

Advantage: Thermal Stability in Electronics

Graphene's negative CTE can be a powerful tool. Most semiconductor substrates, like silicon, have a positive CTE. The mismatch causes mechanical stress and potential failure in electronic devices as they heat up and cool down.

By integrating graphene into a device, its negative expansion can compensate for the substrate's positive expansion. This allows engineers to create composite structures with a near-zero overall CTE, leading to exceptional thermal stability and reliability.

Challenge: Mismatch in Composites

When using graphene as a reinforcement material in a polymer or metal matrix, its negative CTE can also be a liability. The surrounding matrix material will expand with heat while the graphene tries to shrink.

This CTE mismatch creates significant internal stress at the interface between the graphene and the matrix. Over repeated thermal cycles, this stress can lead to micro-cracks, delamination, and ultimately, failure of the composite material.

Factor: Dependence on Form and Substrate

The measured CTE of graphene is not a universal constant. It is highly sensitive to its physical condition.

Factors such as the substrate it is placed on, the number of layers (single-layer vs. few-layer vs. graphite), and the presence of defects can all influence its thermal expansion behavior. The pristine, defect-free graphene produced under controlled conditions (like low-pressure chemical vapor deposition) will behave differently than graphene in a bulk composite.

Applying This Knowledge to Your Project

Understanding graphene's CTE is about managing its unique properties to achieve a specific outcome.

- If your primary focus is thermal stability for electronics: Use graphene to create a composite with a near-zero CTE by balancing its negative expansion against a substrate's positive expansion.

- If your primary focus is creating strong, heat-resistant composites: You must model and manage the internal stresses caused by the CTE mismatch between graphene and the host matrix material.

- If your primary focus is sensing or actuation: Leverage the predictable contraction as a direct response to thermal input for creating highly sensitive thermal sensors or actuators.

Ultimately, mastering graphene's thermal properties is key to unlocking its potential in advanced materials and devices.

Summary Table:

| Property | Value / Description |

|---|---|

| Coefficient of Thermal Expansion (CTE) | Approximately -3.26 × 10⁻⁶ K⁻¹ at room temperature |

| Behavior | Contracts when heated (negative CTE) |

| Key Mechanism | Out-of-plane atomic vibrations (the "Membrane Effect") |

| Primary Advantage | Can compensate for positive CTE in substrates for superior thermal stability in electronics |

| Primary Challenge | Creates internal stress in composites due to CTE mismatch with the matrix material |

Ready to leverage graphene's unique properties in your lab?

Understanding material behavior is the first step to innovation. KINTEK specializes in providing the high-quality lab equipment and consumables you need to precisely test and apply advanced materials like graphene.

Whether you're developing next-generation electronics or stronger composites, we have the tools to support your research.

Contact our experts today to discuss how we can help you achieve your project goals.

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What are carbon nanotubes used for and why? Unlock Next-Generation Material Performance

- What are sputtering targets? Essential for High-Quality Thin Film Deposition

- What are the factors that affect thin film? Master the 4 Key Pillars of Thin Film Engineering

- What are diamond coated tools used for? Conquer Abrasive Materials with Superior Tool Life

- What is the purpose of thin film deposition? Enhance Surface Properties for Superior Performance

- What is CVD lab grown diamond? A Real Diamond Grown in a Lab

- What is the effect of deposition rate on thin film? Control Microstructure for Better Performance

- What is sputtering in engineering? A Guide to High-Quality Thin Film Deposition