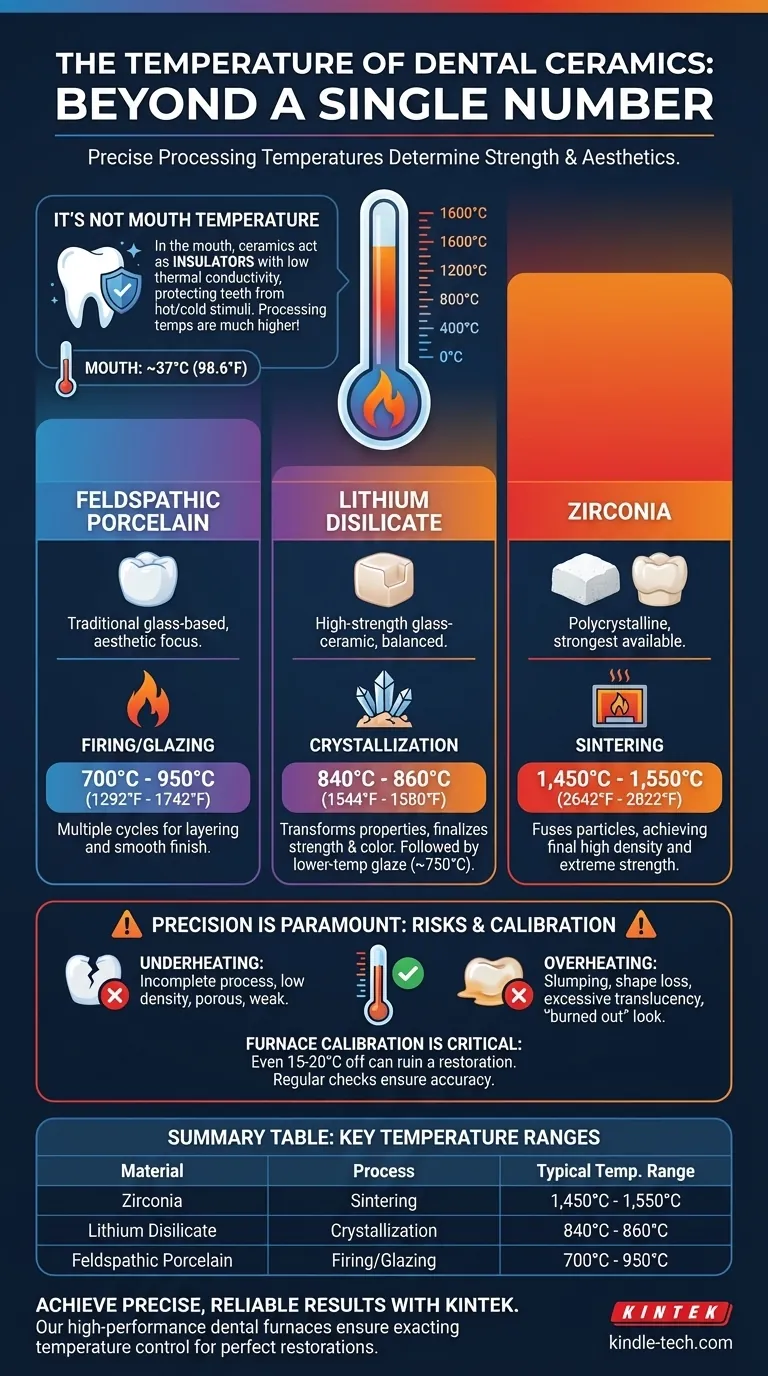

The temperature of a dental ceramic is not one specific value. Instead, it refers to a precise processing temperature that varies significantly based on the type of ceramic and the manufacturing step. These temperatures can range from around 700°C (1292°F) for a final porcelain glaze to over 1,500°C (2732°F) for sintering a high-strength zirconia core.

The central takeaway is that "temperature" in the context of dental ceramics almost always refers to the firing or sintering temperature required in a dental furnace to achieve the material's final strength and aesthetic properties, not a temperature it holds in the mouth. This crucial value is dictated entirely by the specific material being used.

Why "Temperature" Is Not a Single Number

To understand the temperature of dental ceramic, you must first consider two critical factors: the material composition and the processing stage. Each combination has a unique and precise temperature requirement.

The Ceramic Material Dictates the Heat

Dental ceramics are a broad family of materials. The three most common types have vastly different processing needs.

- Feldspathic Porcelains: These are traditional glass-based ceramics, prized for their aesthetics. They are fired at relatively lower temperatures.

- Lithium Disilicate: A high-strength glass-ceramic (e.g., Ivoclar's E.max), it offers a blend of strength and beauty. It requires a specific crystallization firing cycle.

- Zirconia: A polycrystalline ceramic (not glass-based), zirconia is the strongest dental ceramic available. It requires the highest processing temperatures to achieve its final density and strength.

The Process Defines the Temperature

A restoration is not made in a single step. Different heating cycles achieve different goals.

- Sintering: This high-temperature process is used for zirconia. It fuses ceramic particles together, causing the material to shrink and become incredibly dense and strong.

- Crystallization Firing: This is specific to materials like lithium disilicate. A pre-crystallized block is milled and then heated, causing crystals to grow within the glass matrix, which dramatically increases its strength and finalizes its color.

- Glazing: This is a final, lower-temperature firing that melts a thin layer on the surface to create a smooth, shiny, and non-porous finish.

A Breakdown of Key Ceramic Temperatures

The correct temperature protocol is the difference between a successful restoration and a complete failure. The manufacturer's instructions are the definitive guide, but the following ranges are typical for each material.

High-Temperature Sintering for Zirconia

Zirconia is milled in an enlarged, chalky, pre-sintered state. The sintering process provides its strength.

The furnace must follow a precise schedule, slowly heating to a peak temperature between 1,450°C and 1,550°C (2642°F - 2822°F) and holding it there for a set time before slowly cooling.

Crystallization & Glazing for Lithium Disilicate

Lithium disilicate is typically milled in a weaker, purple-blue state. The crystallization firing transforms its properties.

This cycle is performed in a porcelain furnace, with a peak temperature of approximately 840°C to 860°C (1544°F - 1580°F). A separate, lower-temperature glaze firing around 750°C may follow.

Firing and Glazing for Feldspathic Porcelain

This classic material is often hand-layered by a technician, with multiple firing cycles.

The exact temperature depends on the specific powder (e.g., dentin, enamel, translucent), but cycles typically range from 700°C to 950°C (1292°F - 1742°F).

Understanding the Trade-offs and Risks

Strict adherence to temperature protocols is non-negotiable for achieving predictable, high-quality results. Deviations can have severe consequences.

The Risk of Overheating or Underheating

Underheating results in an incomplete process. For zirconia, this means low density and weakness. For porcelain, it results in a porous, opaque, and structurally compromised restoration.

Overheating is just as damaging. It can cause the restoration to slump and lose its shape, and it can negatively affect aesthetics by creating excessive translucency or a "burned out" look.

Furnace Calibration is Critical

A dental furnace that is off by even 15-20 degrees can ruin a restoration. The digital display may read 1500°C, but the actual chamber temperature could be significantly different.

For this reason, regular calibration by the dental technician using standardized kits is an essential quality control measure to ensure consistency and accuracy.

Temperature in the Patient's Mouth

Once the restoration is complete and cemented, its temperature properties become a benefit. Dental ceramics have low thermal conductivity.

This means they act as excellent insulators, protecting the underlying natural tooth from the shock of hot coffee or cold ice cream. This is a key reason they feel more comfortable and natural than old metal-based crowns.

Making the Right Choice for Your Goal

The required temperature is a direct function of the material you choose to meet a specific clinical or aesthetic need.

- If your primary focus is producing the strongest possible crowns for posterior teeth: You will be working with zirconia and must use a high-temperature sintering furnace capable of reaching and holding temperatures over 1,500°C.

- If your primary focus is creating highly aesthetic anterior restorations like veneers: You are likely using feldspathic porcelain or lithium disilicate, which require a programmable porcelain furnace for lower-temperature cycles (700°C - 950°C) that demand precise control for color and translucency.

- If you are a patient concerned about temperature sensitivity: Rest assured that the final ceramic restoration is an excellent insulator designed to protect your tooth from hot and cold stimuli far better than natural enamel might.

Ultimately, mastering dental ceramics means moving beyond a single number and understanding temperature as a precise tool to unlock the unique potential of each material.

Summary Table:

| Material | Process | Typical Temperature Range |

|---|---|---|

| Zirconia | Sintering | 1,450°C - 1,550°C (2642°F - 2822°F) |

| Lithium Disilicate | Crystallization | 840°C - 860°C (1544°F - 1580°F) |

| Feldspathic Porcelain | Firing/Glazing | 700°C - 950°C (1292°F - 1742°F) |

Achieve precise, reliable results with every restoration. The quality of your dental ceramics depends on the accuracy of your furnace. KINTEK specializes in high-performance dental furnaces and lab equipment designed for the exacting temperature control required for sintering zirconia, crystallizing lithium disilicate, and glazing porcelain. Ensure your lab produces strong, aesthetically perfect restorations every time. Contact our experts today to find the perfect furnace for your ceramic workflow.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the function of a high-vacuum sintering furnace in 3Y-TZP? Enhance Dental Restoration Quality

- What factors are important to consider when choosing a dental sintering furnace? Match Your Workflow for Optimal Results

- Are ceramic crowns stain-resistant? Discover the Secret to a Lasting, Bright Smile

- Are zirconia crowns biocompatible? The Ultimate Guide to Safe, Metal-Free Dental Restorations

- What is in a dental laboratory? Discover the High-Tech Hub Creating Your Perfect Smile

- What is a dental furnace? The Precision Oven for Creating Strong, Lifelike Dental Restorations

- How is zirconia sintered? A Guide to the High-Temperature Transformation Process

- What is the strongest type of zirconia? A Guide to Choosing the Right Dental Zirconia