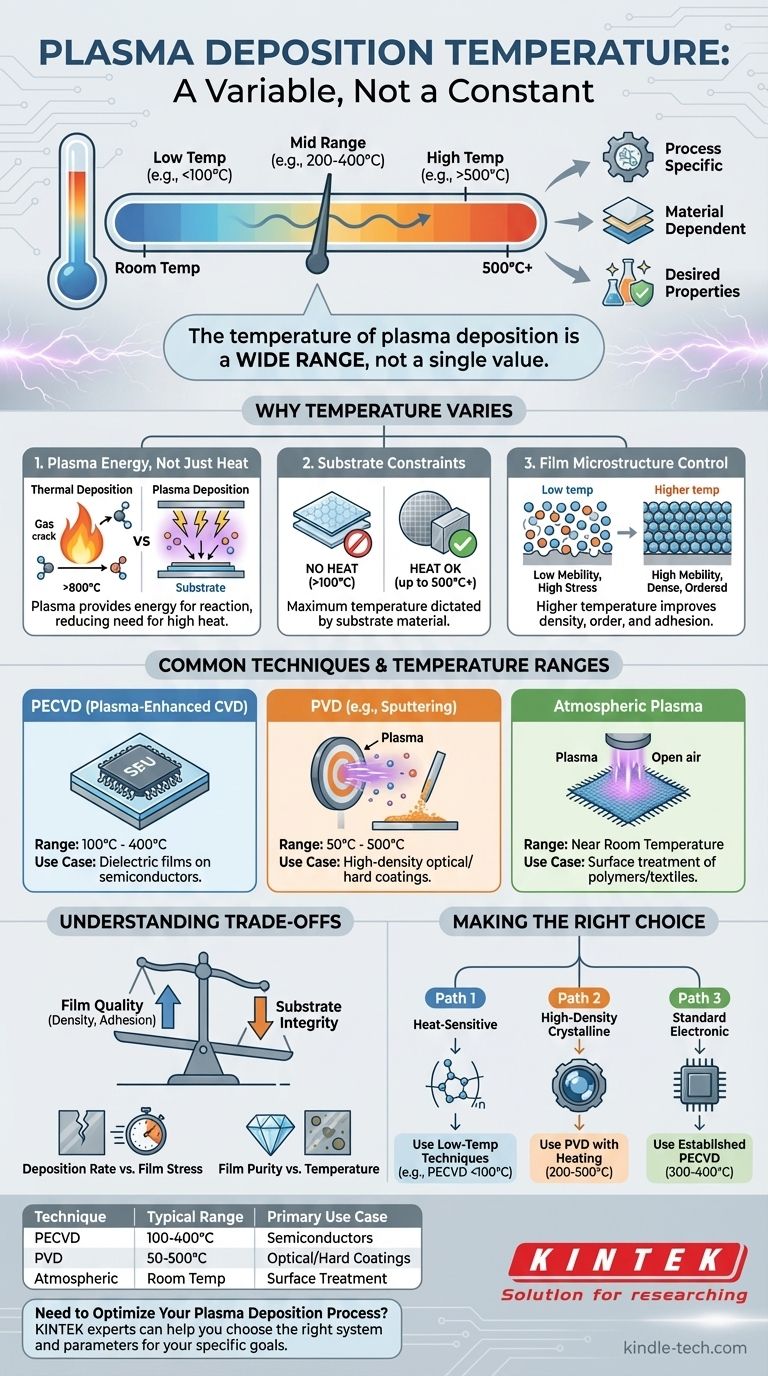

The temperature of plasma deposition is not a single value but rather a wide range that depends entirely on the specific process, the material being deposited, and the properties desired in the final film. While some techniques operate near room temperature (25°C), others utilize substrate heating up to 500°C or more to control the film's structure and quality. The key is that plasma provides the energy for the reaction, reducing the need for the high temperatures typical of purely thermal methods.

Plasma deposition's defining advantage is its ability to deposit high-quality films at significantly lower substrate temperatures than conventional methods like thermal Chemical Vapor Deposition (CVD). This allows for the coating of heat-sensitive materials, but the chosen temperature remains a critical lever for controlling film properties like density, stress, and adhesion.

Why Temperature is a Variable, Not a Constant

The core principle of plasma deposition is using an energized gas (plasma) to drive the deposition process, rather than relying solely on high heat. This fundamentally changes the role of temperature.

The Role of Plasma Energy

In traditional thermal deposition, high temperatures (often >800°C) are required to provide enough energy to break down precursor gases and form a film. In plasma deposition, collisions with energetic electrons and ions within the plasma provide this energy. This means the substrate itself does not need to be intensely heated.

Substrate Material is the Primary Constraint

The maximum allowable temperature is almost always dictated by the substrate material. Coating a polymer or plastic requires a process below its glass transition temperature, often under 100°C. In contrast, depositing a film on a silicon wafer or metal component allows for much higher temperatures to be used to enhance film properties.

Temperature Controls Film Microstructure

Even when not required for the basic reaction, substrate temperature is a powerful tool. Higher temperatures give deposited atoms more surface mobility, allowing them to arrange into a denser, more ordered, and less-stressed film. This is a deliberate choice made by process engineers to achieve specific performance goals.

Common Techniques and Their Temperature Ranges

Different plasma deposition methods operate in distinct temperature regimes, each suited for different applications.

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

PECVD is the classic example of a low-temperature process. It is widely used in the semiconductor industry to deposit dielectric films like silicon nitride (SiN) and silicon dioxide (SiO₂) on devices that cannot withstand high heat. Typical substrate temperatures range from 100°C to 400°C.

Physical Vapor Deposition (PVD)

Processes like magnetron sputtering fall under the PVD category. Here, plasma is used to bombard a target, ejecting atoms that then deposit onto the substrate. While the process can run without external heating ("room temperature"), it is common to heat the substrate from 50°C to 500°C to improve film density and adhesion, especially for optical or hard coatings.

Atmospheric Pressure Plasma Deposition

This emerging technique operates in the open air, not a vacuum chamber. Because it is often used for rapid surface treatment of heat-sensitive materials like textiles and polymers, it almost always runs at near-room temperature. The goal is typically surface modification (e.g., improving wettability) rather than building a thick film.

Understanding the Trade-offs

Choosing a deposition temperature involves balancing competing factors. It is not simply a matter of "lower is better."

Film Quality vs. Substrate Integrity

The primary trade-off is between achieving the highest possible film quality (dense, stable, good adhesion) and preserving the integrity of the substrate. Higher temperatures generally yield better films but limit your choice of substrate materials.

Deposition Rate vs. Stress

While not always a direct relationship, temperature can influence deposition rate. More importantly, depositing at too low a temperature can result in films with high internal stress, which can cause cracking or delamination over time. Gentle heating can help relax this stress as the film grows.

Purity vs. Temperature

In PECVD, low-temperature processes can sometimes result in the incorporation of unwanted elements, such as hydrogen, into the film. This can alter its electrical or optical properties. Increasing the temperature can help drive off these volatile impurities during deposition, leading to a purer film.

Making the Right Choice for Your Goal

Your optimal deposition temperature is determined by your primary objective and material constraints.

- If your primary focus is coating heat-sensitive substrates (like polymers or plastics): You must use low-temperature techniques like PECVD or atmospheric plasma, keeping the process temperature below the material's degradation point (often <100°C).

- If your primary focus is achieving high-density, crystalline films (for optics or wear resistance): You should use a process like PVD with deliberate substrate heating, often between 200°C and 500°C, provided the substrate can tolerate it.

- If your primary focus is depositing standard electronic films (like SiN on silicon): A well-established PECVD process in the 300°C to 400°C range is the industry standard for balancing quality and throughput.

Ultimately, temperature in plasma deposition is a critical control parameter used to tailor the outcome of the process to your specific application.

Summary Table:

| Technique | Typical Temperature Range | Primary Use Case |

|---|---|---|

| PECVD | 100°C - 400°C | Dielectric films on semiconductors |

| PVD (e.g., Sputtering) | 50°C - 500°C | High-density optical/hard coatings |

| Atmospheric Plasma | Near Room Temperature | Surface treatment of polymers/textiles |

Need to Optimize Your Plasma Deposition Process?

Choosing the right temperature is critical for your film's density, adhesion, and performance. The experts at KINTEK specialize in lab equipment and consumables for plasma deposition. We can help you select the right system and parameters to achieve your specific goals, whether you're coating heat-sensitive polymers or need high-quality crystalline films.

Contact our experts today to discuss your application and get a tailored solution!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition