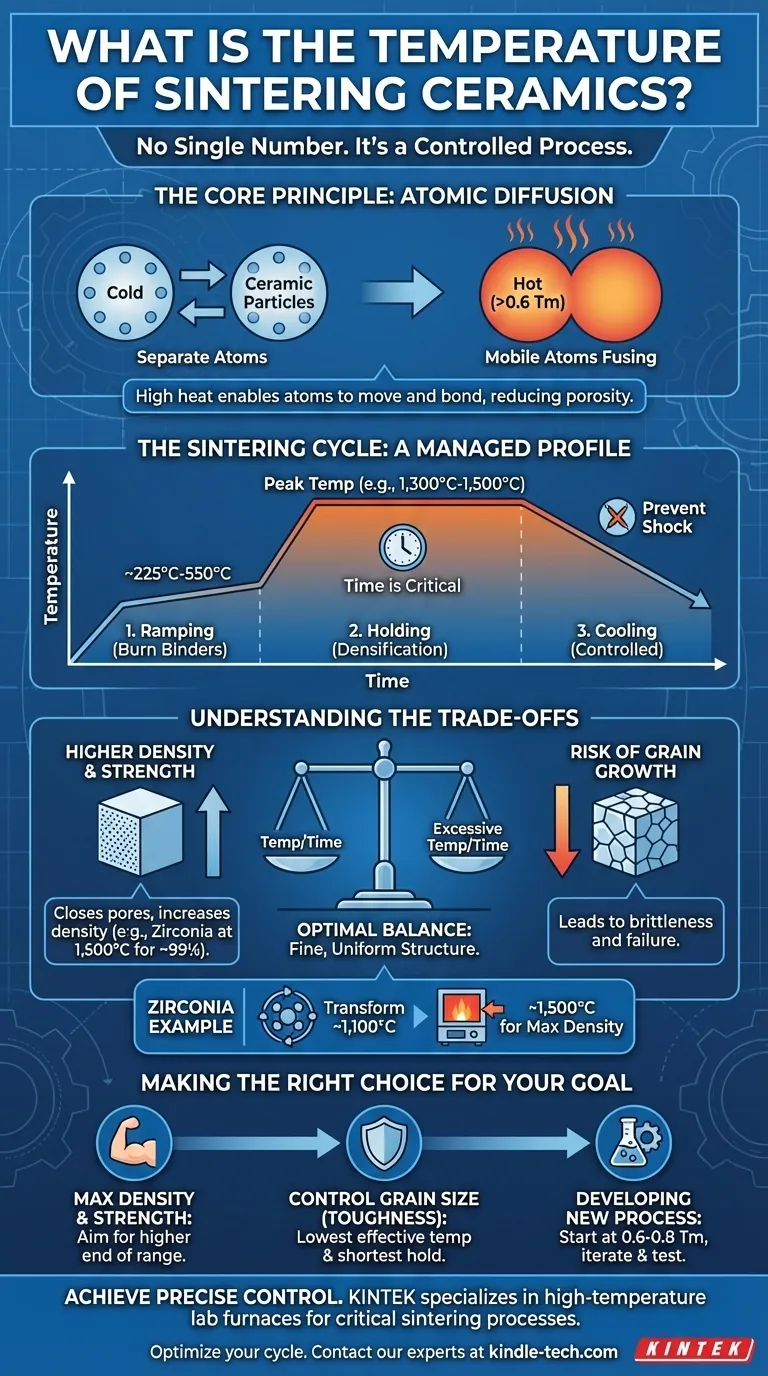

There is no single temperature for sintering ceramics. Instead, the correct temperature is determined by the specific material and the desired final properties. As a general rule, sintering requires a temperature greater than 60% of the material's absolute melting temperature (Tm), which often falls in the range of 1,300°C to 1,500°C for common technical ceramics like zirconia.

The core takeaway is that sintering temperature is not a fixed number but a critical variable in a controlled process. The goal is to apply just enough thermal energy to fuse ceramic particles into a dense, solid mass without causing defects from excessive heat.

The Fundamental Principle: Temperature and Diffusion

The primary purpose of heating a ceramic is to enable atomic diffusion. At high temperatures, atoms at the contact points between individual ceramic powder particles become mobile, allowing the particles to fuse together.

The "Rule of Thumb": Sintering and Melting Point (Tm)

A widely accepted starting point is that effective sintering begins at temperatures above 0.6 times the material's melting point (Tm).

This is not a strict law but a guideline. It signifies the temperature at which atoms have enough energy to move and bond, reducing the empty space (porosity) between particles.

How Temperature Drives Densification

As temperature increases, the rate of atomic diffusion accelerates. This process reduces the total surface area of the powder mass, closes off pores, and causes the entire component to shrink and increase in density.

The ultimate goal is to approach the material's theoretical maximum density, creating a strong, non-porous final part.

Sintering Is a Process, Not a Single Temperature

Achieving the right properties requires a carefully managed heating and cooling profile, known as a sintering cycle. Simply reaching a peak temperature is not enough.

The Sintering Cycle: Ramping, Holding, and Cooling

A typical cycle involves several stages. For example, a part might be heated slowly to a low temperature (e.g., 225°C - 550°C) to burn off binders from the manufacturing process.

The temperature is then ramped up more quickly to the peak sintering temperature (e.g., 1,300°C) and held for a specific duration. This "hold" or "soak" time is where the majority of densification occurs.

Finally, the part is cooled in a controlled manner to prevent thermal shock and cracking.

The Example of Zirconia

Zirconia provides a perfect illustration of this principle. It undergoes a crucial crystal structure change (phase transformation) around 1,100°C to 1,200°C.

However, to achieve the highest possible density (approaching 99%), furnaces often fire zirconia closer to 1,500°C. This demonstrates that the optimal sintering temperature is often significantly higher than the material's transformation temperature.

Understanding the Trade-offs

Choosing a sintering temperature involves balancing competing factors. It is a critical decision that directly impacts the final mechanical and physical properties of the ceramic part.

Temperature vs. Final Density

Higher temperatures generally lead to higher density and, consequently, greater strength. The zirconia example shows that firing at 1,500°C yields a denser part than firing at 1,200°C.

This is a direct trade-off between the energy cost of the furnace and the performance requirements of the final component.

The Risk of Over-Sintering

Excessive temperature or holding the part at the peak temperature for too long can lead to grain growth. While the part may be dense, abnormally large crystal grains can make the ceramic brittle and prone to failure.

The ideal process achieves maximum density while maintaining a fine, uniform grain structure.

Time as a Critical Factor

The duration of the hold at peak temperature is as important as the temperature itself. A longer hold time (e.g., 180 minutes vs. 40 minutes) allows more time for diffusion, which can increase density but also risks undesirable grain growth.

Making the Right Choice for Your Goal

The optimal sintering profile depends entirely on your objective. Use these principles to guide your decision-making process.

- If your primary focus is achieving maximum density and strength: You will likely need to sinter at the higher end of the material's recommended range, often significantly above any phase transformation temperatures.

- If your primary focus is controlling grain size to ensure toughness: You should aim for the lowest effective temperature and shortest hold time that achieves your minimum required density.

- If you are developing a new ceramic process: Start with the guideline of 0.6-0.8 times the material's melting point (Tm) and conduct iterative tests to find the ideal balance of temperature, time, and final properties.

Mastering the sintering profile gives you precise control over the final performance of your ceramic material.

Summary Table:

| Ceramic Material | Typical Sintering Range | Key Consideration |

|---|---|---|

| Zirconia | ~1,300°C to 1,500°C | Higher temperatures (e.g., 1,500°C) achieve near 99% density. |

| General Technical Ceramics | >60% of Melting Point (Tm) | A starting guideline; optimal temperature balances density and grain growth. |

Achieve Precise Control Over Your Ceramic Properties

Mastering the sintering process is key to producing high-performance ceramic components with the exact density, strength, and toughness you require. The right laboratory furnace is essential for executing the precise temperature profiles and hold times detailed in this article.

KINTEK specializes in lab equipment and consumables, serving the precise needs of materials science and research laboratories. Our range of high-temperature furnaces is designed to deliver the exact control and reliability needed for critical sintering processes.

Let us help you optimize your sintering cycle. Contact our experts today to discuss your specific ceramic application and find the ideal furnace solution for your research or production goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of centrifugal extraction? Achieve High-Speed, High-Purity Separations

- What are the advantages and disadvantages of filter press? Unlock Superior Solid-Liquid Separation

- How deep does XRF penetrate? A Guide to Surface-Sensitive Analysis Depth

- What is the characterization of bio-oil? A Deep Dive into Its Properties and Potential

- What is the rotary method of extraction? Harness High-Volume Thermal Processing for Your Materials

- What is the unit of coating thickness? Avoid Costly Errors with Microns vs. Mils

- How efficient is pyrolysis plant? Maximize Your Waste-to-Energy Conversion

- What are the various biomass conversion technologies presently used? A Guide to Thermochemical & Biochemical Methods