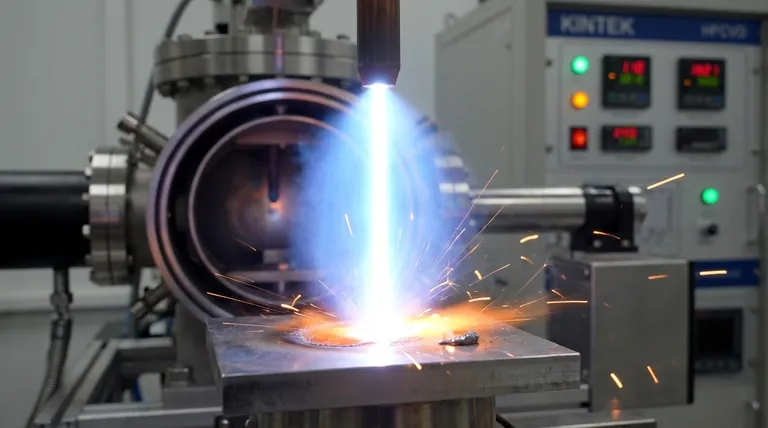

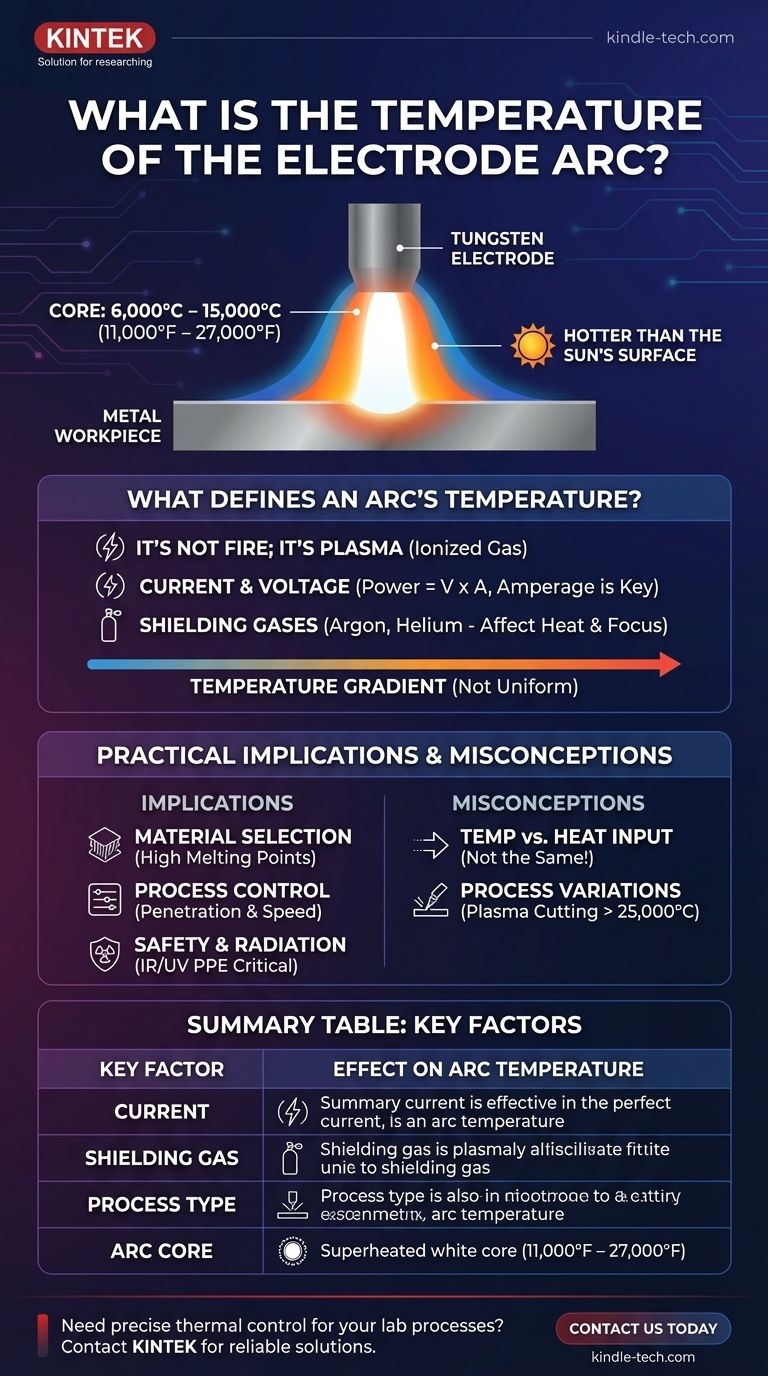

An electric arc is intensely hot, with the core temperature of an electrode arc typically reaching between 6,000°C and 15,000°C (approximately 11,000°F to 27,000°F). This temperature, which is hotter than the surface of the sun, is not a fixed number and varies significantly based on the specific process, electrical settings, and gases involved.

The immense temperature of an electrode arc isn't a static value but a dynamic property of the plasma it creates. Understanding the arc means shifting focus from a single number to the factors that govern its energy: electrical current, voltage, and the surrounding gas environment.

What Defines an Arc's Temperature?

The extreme heat of an electrode arc is not a product of combustion or burning. It is a fundamental physical phenomenon driven by the creation of plasma and the flow of electrical energy.

It's Not Fire; It's Plasma

An electric arc is a sustained electrical discharge through a gas, creating a column of superheated, ionized gas known as plasma.

This plasma is the fourth state of matter, where atoms are stripped of their electrons. The intense thermal energy is a direct result of this high-energy state.

The Role of Current and Voltage

The energy delivered by the arc is a function of its power (Power = Voltage x Current).

Current (amperage) has the most significant impact on temperature. Increasing the current forces more electrons through the plasma column, increasing collisions and generating more intense heat.

The Influence of Shielding Gases

In processes like welding, shielding gases such as argon, helium, or carbon dioxide are used to protect the arc and the molten material.

These gases are not inert bystanders; they have different thermal properties. Helium, for instance, has high thermal conductivity and creates a broader, hotter arc compared to argon, which produces a more focused and stable arc.

A Temperature Gradient, Not a Single Value

The temperature of an arc is not uniform. It has an intensely hot central core or plasma column where the highest temperatures are found.

Surrounding this core are cooler outer layers. When a temperature is cited, it almost always refers to the maximum temperature within this central column.

Understanding the Practical Implications

The temperature of the arc is not just an academic number; it directly dictates how the arc performs in a real-world application, from joining metals to ensuring operator safety.

Impact on Material Selection

The ability to melt, and even vaporize, any known metal is a direct consequence of the arc's temperature.

This is why electrode materials (like tungsten) must have exceptionally high melting points. It also dictates which base materials can be welded or cut effectively.

Control Over the Process

In welding, controlling the arc's energy is how an operator controls the outcome.

A hotter arc, achieved through higher amperage, results in deeper penetration into the base material. A cooler arc provides less penetration, suitable for thin materials or delicate work.

Safety and Radiation

An environment hotter than the sun's surface releases enormous amounts of energy, not just as heat but as intense infrared (IR) and ultraviolet (UV) radiation.

This radiation is the cause of "welder's flash" (arc eye) and skin burns, making proper personal protective equipment (PPE) absolutely critical.

Common Misconceptions to Avoid

To truly master processes involving electric arcs, it's crucial to move beyond simple temperature figures and understand the nuances of heat transfer.

Confusing Arc Temperature with Heat Input

A very hot arc does not automatically mean more heat is transferred to the workpiece.

Heat input is a function of power and travel speed. A fast-moving, high-temperature arc may transfer less total heat to the material than a slower-moving, cooler arc, a critical factor in controlling distortion.

Assuming All Arcs Are the Same

Different processes use different types of arcs. A TIG welding arc is designed for precision and stability.

In contrast, a plasma cutting arc is forced through a small, constricting nozzle. This dramatically increases the plasma's temperature and velocity, allowing it to blast through metal rather than just melt it. These arcs can exceed 25,000°C (45,000°F).

Applying This to Your Goal

Your objective determines which arc characteristics are most important. Understanding the link between temperature and performance allows you to tailor the process to the task.

- If your primary focus is achieving deep penetration in welding: You need to maximize the energy density at the arc's core, often by increasing amperage and using a shielding gas with high thermal conductivity, like a helium mix.

- If your primary focus is high-speed material cutting: The goal is maximum temperature and plasma velocity, which is why plasma cutting systems use a constricting orifice and high gas pressure to create a superheated, focused jet.

- If your primary focus is controlling distortion on thin materials: You need to minimize total heat input by using lower amperage and a faster travel speed, even if the core arc temperature remains high.

Ultimately, mastering the electric arc comes from understanding it not as a simple heat source, but as a controllable column of high-energy plasma.

Summary Table:

| Key Factor | Effect on Arc Temperature |

|---|---|

| Electrical Current (Amperage) | Higher current increases temperature significantly. |

| Shielding Gas (e.g., Argon, Helium) | Gas thermal properties alter arc focus and heat. |

| Process Type (e.g., TIG vs. Plasma Cutting) | Plasma cutting arcs can exceed 25,000°C. |

| Arc Core vs. Outer Layers | Temperature is a gradient, not a single uniform value. |

Need precise thermal control for your lab processes? Whether your goal is material joining, cutting, or high-temperature research, understanding and managing extreme heat is critical. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable solutions for thermal applications. Let our experts help you select the right equipment to achieve superior results and enhance your lab's efficiency. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- Anti-Cracking Press Mold for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently