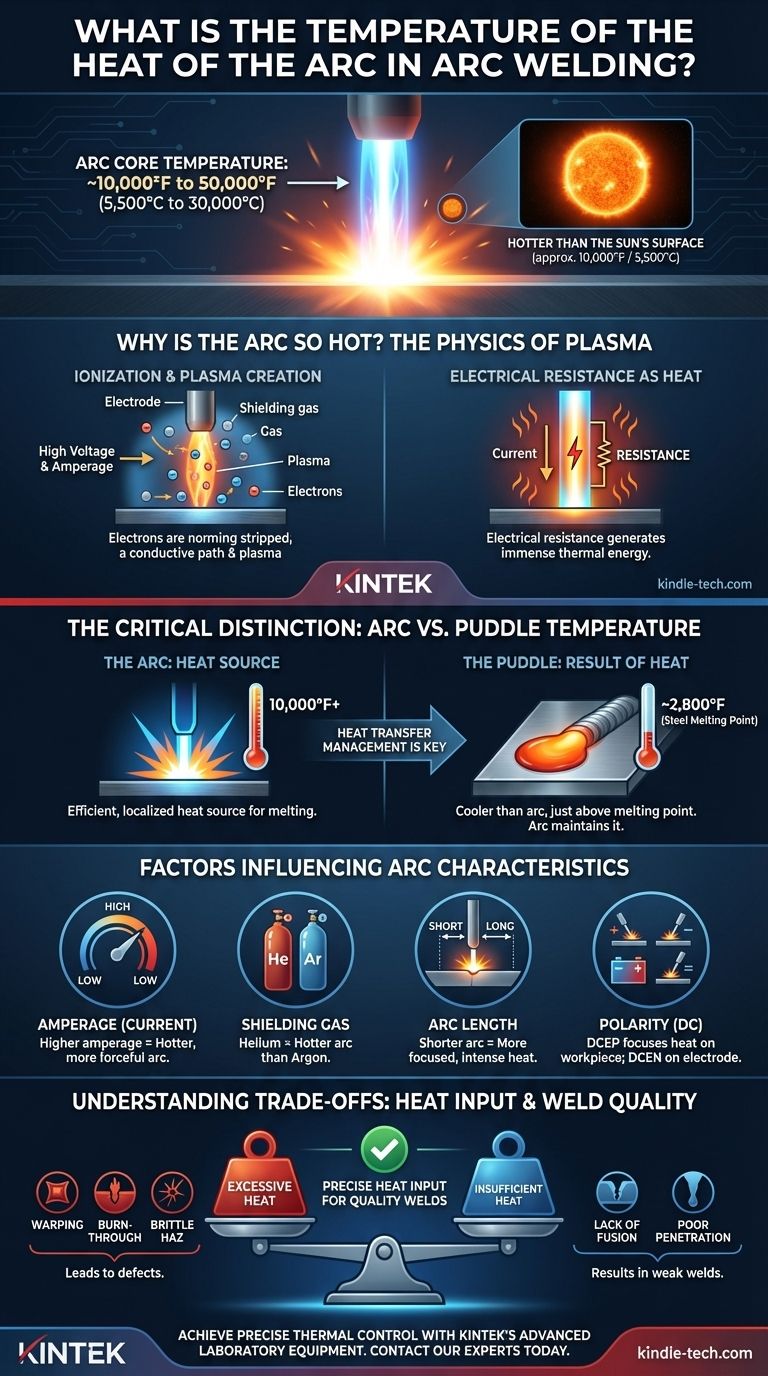

The temperature at the core of a welding arc is staggeringly high, reaching from approximately 10,000°F to over 50,000°F (5,500°C to 30,000°C). This range is far hotter than the surface of the sun, which is around 10,000°F / 5,500°C. This extreme heat is necessary to instantly melt the base metal and filler material, creating the molten weld puddle that forms the weld.

The core insight is not the specific temperature, but understanding the difference between the arc's heat and the actual heat transferred to the workpiece. A welder's skill lies in controlling the factors that manage this heat transfer, as this is what determines the quality and integrity of the final weld.

Why is the Arc So Hot? The Physics of Plasma

The intense heat of a welding arc is a direct result of converting electrical energy into thermal energy through a state of matter called plasma.

Creating the Plasma State

When a high-voltage, high-amperage electrical current is initiated between the electrode and the workpiece, it strips electrons from the atoms of the shielding gas. This process, called ionization, creates a superheated, electrically conductive column of gas known as plasma.

Electrical Resistance as Heat

This plasma column is not a perfect conductor. It has electrical resistance, and as the massive current of the welding power source flows through it, this resistance generates an immense amount of thermal energy. This is the source of the arc's incredible temperature.

The Critical Distinction: Arc vs. Puddle Temperature

Many professionals mistakenly use the terms "arc temperature" and "weld temperature" interchangeably. Understanding the difference is fundamental to controlling the welding process.

The Arc: The Heat Source

Think of the welding arc as the burner on a gas stove. Its purpose is to be an incredibly efficient, localized heat source. Its temperature of 10,000°F+ is what allows it to do its job of melting metal on contact.

The Puddle: The Result of Heat Input

The molten weld puddle itself is much cooler than the arc. Its temperature is only slightly above the melting point of the metal being welded. For example, the melting point of steel is around 2,800°F (1,538°C). The arc's energy is used to create and maintain this puddle, not to raise the entire puddle to the arc's temperature.

Factors That Influence Arc Characteristics

The temperature and behavior of the arc are not static. They are dynamic variables that a skilled welder manipulates to achieve the desired result.

Shielding Gas Composition

The type of shielding gas used has a profound effect on the arc. Helium, for instance, has higher thermal conductivity than Argon, resulting in a hotter arc that provides a broader heat pattern and deeper penetration, which is useful for thick aluminum or copper.

Amperage (Current)

Amperage is the most direct control over heat input. Increasing the amperage forces more electrical current through the plasma, increasing its resistance and generating a hotter, more forceful arc.

Arc Length

Arc length—the distance between the electrode and the workpiece—affects the concentration of heat. A shorter arc is more focused and intense, concentrating the heat in a smaller area. A longer arc is less stable and disperses the heat over a wider area.

Polarity (DC Welding)

In DC welding, polarity determines where the majority of the heat is focused.

- DCEP (Direct Current, Electrode Positive): About two-thirds of the heat is concentrated on the workpiece, providing deeper penetration. This is standard for Stick and MIG welding.

- DCEN (Direct Current, Electrode Negative): The heat is concentrated on the electrode. This is essential for TIG welding, as it prevents melting the tungsten electrode while melting the workpiece.

Understanding the Trade-offs: Heat Input and Weld Quality

The goal is not simply to create the hottest arc possible. The goal is to deliver the precise amount of heat needed for a specific joint.

The Danger of Excessive Heat

Too much heat input, caused by high amperage or slow travel speed, leads to serious defects. These include warping (distortion), burn-through on thin materials, and a large, brittle Heat-Affected Zone (HAZ) that compromises the strength of the base metal.

The Problem with Insufficient Heat

Too little heat input, from low amperage or fast travel speed, is just as bad. It results in a weak weld with lack of fusion (where the weld metal doesn't properly fuse to the base metal) and poor penetration.

How to Apply This to Your Project

Your objective is to manipulate the arc's characteristics to manage heat input for your specific application.

- If your primary focus is welding thin materials: Your goal is to minimize heat input by using lower amperage, a faster travel speed, and a process (like TIG) or gas that allows for precise, low-energy control.

- If your primary focus is achieving deep penetration on thick plate: You need to maximize effective heat input by using higher amperage, a slower travel speed, and a process/gas combination (like DCEP with a high-helium gas) that drives heat into the material.

- If your primary focus is preserving the metal's properties: You must carefully control the total heat input by balancing amperage and travel speed to keep the Heat-Affected Zone (HAZ) as small as possible.

Ultimately, mastering the arc means viewing its temperature not as a static number, but as a dynamic tool you control to achieve a perfect weld.

Summary Table:

| Welding Factor | Effect on Arc Temperature & Heat Input |

|---|---|

| Shielding Gas | Helium creates a hotter arc than Argon for deeper penetration |

| Amperage | Higher amperage increases arc temperature and force |

| Arc Length | Shorter arc = more focused, intense heat |

| Polarity (DC) | DCEP focuses heat on workpiece; DCEN on electrode |

Achieve precise thermal control in your welding processes with KINTEK's advanced laboratory equipment. Whether you're developing new welding techniques, testing material integrity, or analyzing the Heat-Affected Zone (HAZ), our high-temperature furnaces, plasma systems, and material testing consumables are designed to support your R&D and quality control needs. Contact our experts today to discuss how our solutions can help you optimize heat input and ensure weld quality.

Get in touch with the KINTEK lab team now!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Small Injection Molding Machine for Lab Use

People Also Ask

- What is the safety factor of a vacuum chamber? Ensuring Structural Integrity Against Implosion

- What is the purpose of using a precision furnace for glass stress relief? Ensure Durability in Molded Glass

- What is vacuum sintering? Achieve Unmatched Purity and Performance for Advanced Materials

- Why use a vacuum drying oven for LAGP pellets? Secure High Performance for All-Solid-State Batteries

- How is a vacuum drying oven utilized in the preparation of polymer-inorganic composite solid electrolytes?

- What is the mechanism of a high-temperature reaction furnace in the thermal decomposition of nickel precursors?

- What are the applications of sintering process? Fabricate Complex Parts with High-Performance Materials

- What is the temperature of the arc in an electric arc furnace? Harnessing Heat Hotter Than the Sun