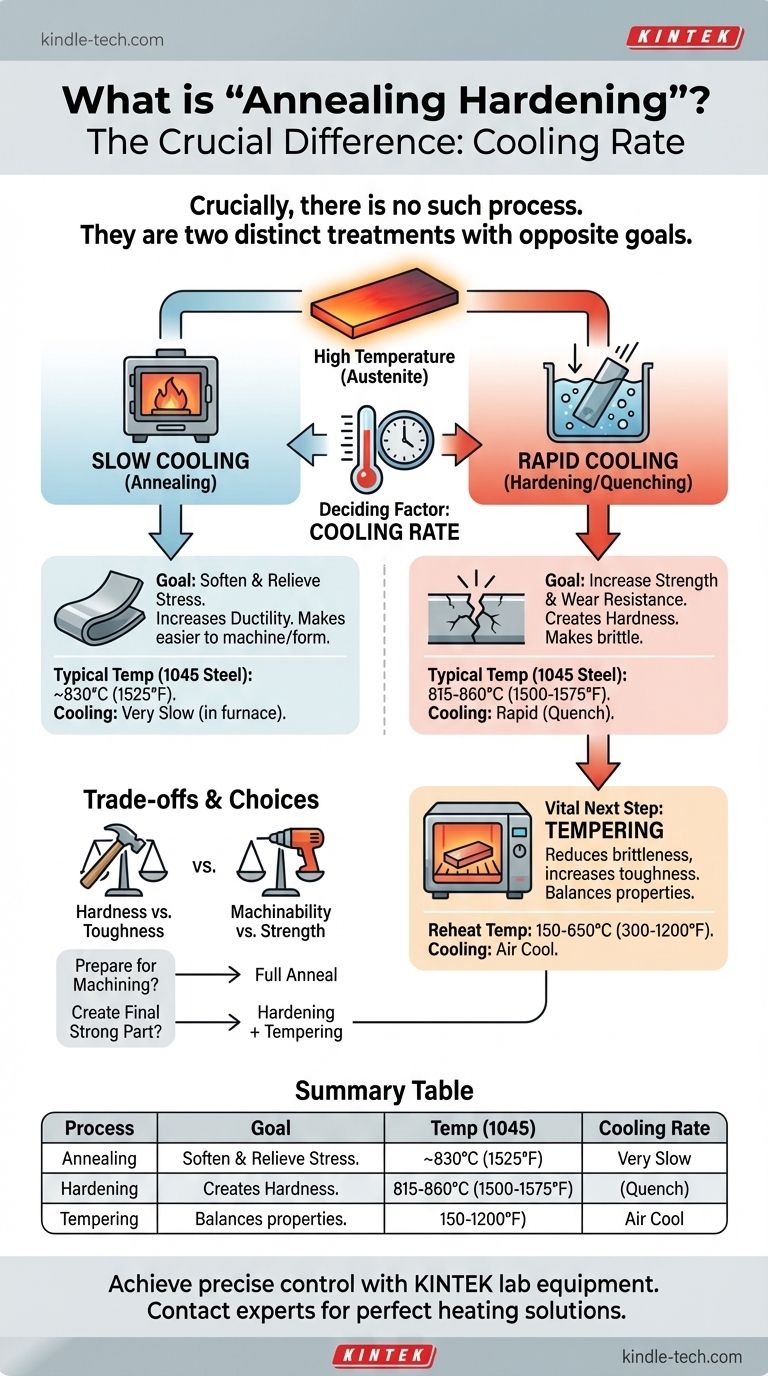

Crucially, there is no standard industrial process called "annealing hardening." These are two distinct heat treatments with opposite goals. Annealing is a process used to soften metal and increase its ductility, while hardening is used to increase its strength and wear resistance.

The core principle to understand is that both processes start by heating the metal to a similar high temperature, but the outcome is determined entirely by the rate of cooling. Slow cooling results in a soft, annealed state, while rapid cooling (quenching) results in a hard state.

The Two Fundamental Goals: Softening vs. Hardening

To select the right temperature and process, you must first be clear about your objective. Are you trying to make the metal easier to work with, or are you trying to create a strong, durable final product?

Annealing: The Goal is to Soften and Relieve Stress

Annealing makes a metal as soft and ductile as possible. This is typically done to prepare the material for subsequent operations like machining, stamping, or forming, or to relieve internal stresses created during previous work.

The process involves heating the steel to a specific temperature, holding it there long enough for the internal structure to transform, and then cooling it very slowly, often by leaving it inside the furnace as it cools.

For a common carbon steel like 1045, a full anneal requires heating to approximately 830°C (1525°F) before the slow cooling cycle begins.

Hardening: The Goal is to Increase Strength

Hardening, also known as quenching, makes steel significantly harder and stronger, but also more brittle. It's used for final parts that require high wear resistance, like tools, knives, and gears.

The process involves heating the steel to a similar temperature as annealing to transform its internal structure (austenitizing), and then cooling it rapidly by plunging it into a medium like water, oil, or brine.

For that same 1045 carbon steel, the hardening temperature range is 815-860°C (1500-1575°F), immediately followed by a rapid quench.

Why the Cooling Rate is the Deciding Factor

Both processes begin by heating steel above a "critical temperature," which rearranges its internal crystal structure into a form called austenite. The final properties of the steel are dictated by what happens as this austenite cools.

Slow Cooling Creates Softness

When cooled slowly, the crystal structure has time to transform into soft, stable forms like ferrite and pearlite. This is the essence of annealing.

Rapid Cooling Traps Hardness

When cooled rapidly (quenched), the structure doesn't have time to transform properly. It becomes trapped in a highly strained, hard, and brittle state called martensite. This is the key to hardening.

The Critical Role of Tempering

A part that has been hardened is often too brittle for practical use. It must undergo a secondary, lower-temperature heat treatment called tempering.

Tempering involves reheating the hardened part to a temperature between 150-650°C (300-1200°F). This process reduces brittleness and increases toughness, with a slight trade-off in hardness. The specific tempering temperature determines the final balance of properties.

Understanding the Trade-offs

Choosing a heat treatment is always a matter of balancing competing properties. It is impossible to maximize all desirable characteristics at once.

Hardness vs. Toughness

This is the primary trade-off. A fully hardened, un-tempered piece of steel is extremely hard but will shatter like glass if struck. Tempering sacrifices some of that peak hardness to gain essential toughness and prevent catastrophic failure.

Machinability vs. Strength

An annealed part is soft, non-abrasive, and easy to machine, but it lacks the strength for demanding applications. A hardened part has high strength but is extremely difficult to machine. This is why machining is almost always done before the final hardening and tempering process.

The Importance of Material Specification

The temperature ranges provided here are general guidelines for plain carbon steels. The exact temperature for any process is critically dependent on the specific alloy. Elements like chromium, manganese, and molybdenum change the critical temperatures and required cooling rates. Always consult the material's data sheet for precise instructions.

Making the Right Choice for Your Goal

Your objective dictates the correct process.

- If your primary focus is to prepare metal for machining, bending, or forming: You need to perform a full anneal, using slow, controlled cooling to achieve maximum softness and relieve internal stress.

- If your primary focus is to create a strong, wear-resistant final part: You need a two-step process of hardening (heating and rapid quenching) followed immediately by tempering to achieve the desired balance of hardness and toughness.

- If your primary focus is to refine the grain structure for improved toughness with some increase in strength: You should consider normalizing, which involves heating to a similar temperature as annealing but allowing the part to cool in still air.

By choosing the correct heat treatment and cooling rate, you gain precise control over the final mechanical properties of your steel.

Summary Table:

| Process | Goal | Temperature Range (for 1045 Steel) | Cooling Rate |

|---|---|---|---|

| Annealing | Soften, increase ductility | ~830°C (1525°F) | Very Slow (in furnace) |

| Hardening | Increase strength, wear resistance | 815-860°C (1500-1575°F) | Rapid (Quench) |

| Tempering | Reduce brittleness after hardening | 150-650°C (300-1200°F) | Air Cool |

Achieve precise control over your material's properties with the right lab equipment.

The success of heat treatments like annealing and hardening depends on precise temperature control and consistent results. KINTEK specializes in high-quality lab furnaces, ovens, and quenching systems designed to meet the exacting demands of metallurgical processes.

Whether you are preparing samples for analysis or hardening final components, our equipment ensures reliability and repeatability.

Let KINTEK be your partner in the lab. Contact our experts today to find the perfect heating solution for your specific application and material requirements.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity

- How does heat treatment process work? Tailor Material Properties for Your Application

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering