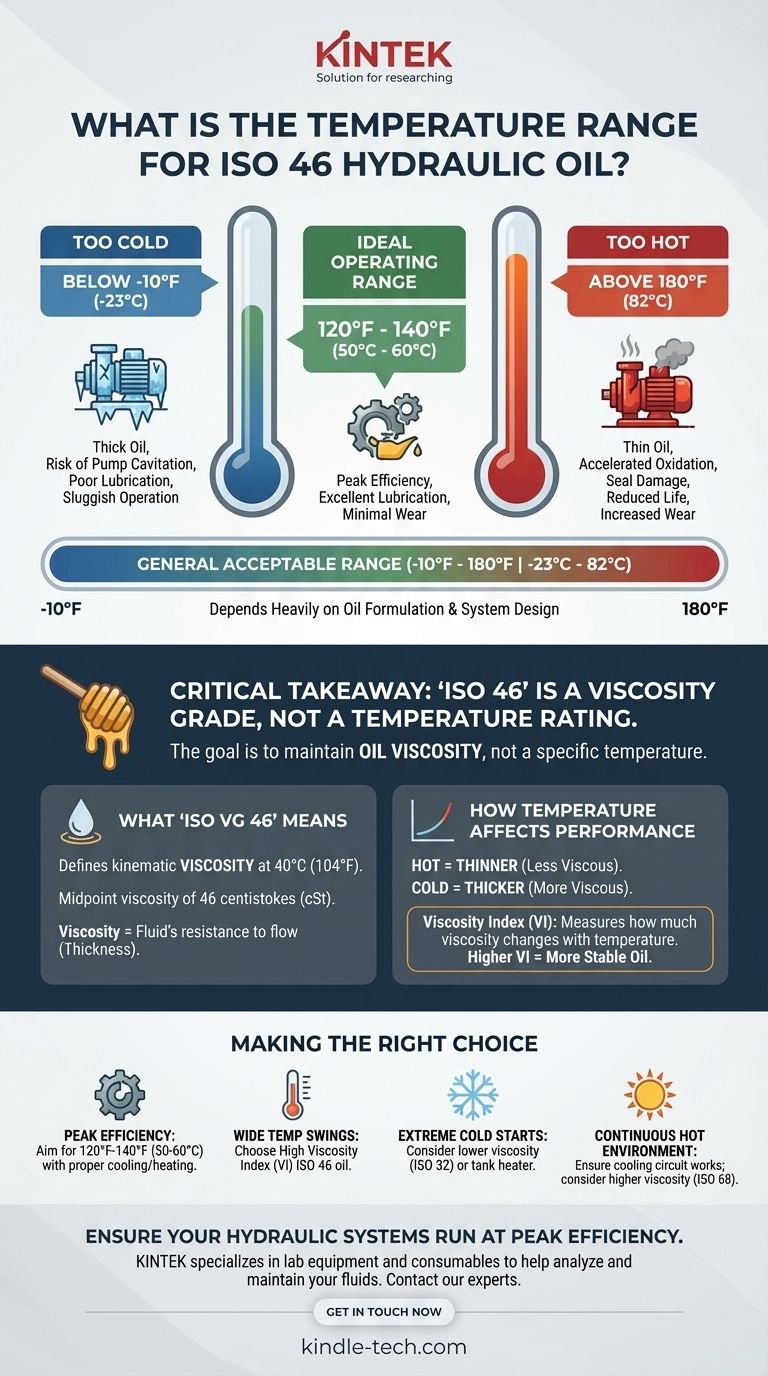

In short, the ideal operating temperature for most systems using ISO 46 hydraulic oil is between 120°F and 140°F (approximately 50°C to 60°C). However, the acceptable operating range is much wider, typically from -10°F to 180°F (-23°C to 82°C), but this depends heavily on the specific oil's formulation and the hydraulic system's design. The temperature itself is less important than the oil's viscosity at that temperature.

The most critical takeaway is that "ISO 46" is not a temperature rating; it is a viscosity grade. The goal is not to maintain a specific temperature, but to keep the oil's viscosity within the range required by your hydraulic system's components, particularly the pump.

What "ISO VG 46" Actually Means

The Viscosity Grade Standard

ISO VG 46 defines the oil's kinematic viscosity at a standard temperature of 40°C (104°F). The "46" means the oil has a midpoint viscosity of 46 centistokes (cSt) at this temperature.

Viscosity is a fluid's resistance to flow. Think of it as the oil's thickness. This is the single most important property of a hydraulic fluid.

Why It's Not a Temperature Rating

The label "ISO 46" only tells you the oil's viscosity at one specific point. It does not tell you how that viscosity will change as the system heats up during operation or cools down when idle.

How Temperature Affects Performance

The Critical Role of the Viscosity Index (VI)

An oil's viscosity changes with temperature. It gets thinner (less viscous) when hot and thicker (more viscous) when cold.

The Viscosity Index (VI) is a number that measures how much the oil's viscosity changes with temperature. A higher VI indicates a more stable oil that thins out less when heated.

Two different ISO 46 oils can have vastly different Viscosity Indexes. A standard hydraulic oil might have a VI of around 100, while a premium, multi-grade fluid could have a VI over 150, making it suitable for a much wider range of operating temperatures.

The Danger of Running Too Hot

When hydraulic oil exceeds its optimal temperature, typically above 180°F (82°C), its viscosity drops dangerously low.

This leads to several problems:

- Increased Wear: The thin oil film cannot adequately separate moving parts, causing metal-to-metal contact and accelerated component wear.

- Reduced Efficiency: Low viscosity increases internal leakage within pumps and motors, wasting energy and reducing system speed and power.

- Accelerated Oxidation: Heat is a catalyst for oxidation, which permanently degrades the oil. This forms sludge and varnish that can clog filters and stick valves. For every 18°F (10°C) increase above 140°F (60°C), the oil's service life is cut in half.

The Danger of Running Too Cold

During a cold start, the oil can be too thick. High viscosity also causes significant problems.

This leads to:

- Pump Cavitation: The thick oil cannot flow into the pump inlet fast enough, creating vapor-filled voids that violently collapse under pressure. This is extremely destructive to pumps.

- Sluggish Operation: The entire system will respond slowly and require much more energy to operate, straining the motor or engine.

- Poor Lubrication: On startup, thick oil may not reach all lubrication points immediately, leading to wear.

Understanding the Trade-offs

Ideal vs. Acceptable Ranges

The ideal range of 120°F to 140°F (50-60°C) is where most systems achieve peak efficiency. The oil is thin enough to flow easily but thick enough to provide excellent lubrication and minimize internal leakage.

The acceptable range is determined by the system's components. A pump manufacturer will specify a minimum and maximum viscosity for proper operation (e.g., 10 cSt to 800 cSt). Your goal is to choose an oil that stays within that viscosity window across your machine's entire operating temperature range.

The Absolute Maximum Temperature

Most mineral-based hydraulic oils should never be allowed to operate continuously above 180°F (82°C). Beyond this point, seals begin to harden, and the oil's chemical breakdown becomes rapid and irreversible.

The Impact of Additives

Modern hydraulic oils contain additive packages that improve their performance. Anti-wear (AW) additives protect components when the oil film is thin, and VI improvers are polymers that help the oil resist thinning at high temperatures. The quality of these additives significantly influences the oil's effective operating range.

Making the Right Choice for Your Goal

- If your primary focus is peak efficiency and longevity: Aim to keep your system's bulk oil temperature stable between 120°F and 140°F (50-60°C) using proper cooling and, if necessary, heating systems.

- If your primary focus is operating in wide temperature swings (e.g., outdoor mobile equipment): Choose a high Viscosity Index (VI) ISO 46 oil. This ensures the oil remains functional whether you are starting up on a cold morning or running hard on a hot afternoon.

- If your primary focus is extreme cold starts: Consider using a lower viscosity grade (like ISO 32) with a high VI, or install a tank heater to warm the fluid before starting the system.

- If your primary focus is continuous operation in a very hot environment: Ensure your system's cooling circuit is clean and functional. You might need to consider a higher viscosity grade (like ISO 68) if the temperature cannot be controlled and the oil is thinning out too much.

Ultimately, selecting the right fluid is about matching the oil's viscosity performance to the demands of your machine and its environment.

Summary Table:

| Temperature Range | Condition | Impact on ISO 46 Oil |

|---|---|---|

| 120°F - 140°F (50°C - 60°C) | Ideal Operating Range | Peak efficiency, excellent lubrication, minimal wear |

| -10°F - 180°F (-23°C - 82°C) | General Acceptable Range | Varies by oil formulation and system design |

| Below -10°F (-23°C) | Too Cold | Thick oil, risk of pump cavitation and poor lubrication |

| Above 180°F (82°C) | Too Hot | Thin oil, accelerated oxidation, seal damage, reduced life |

Ensure your hydraulic systems run at peak efficiency and avoid costly downtime. The right fluid and maintenance strategy are critical for performance. KINTEK specializes in lab equipment and consumables, providing the tools and expertise to help you analyze and maintain your hydraulic fluids effectively.

Contact our experts today to discuss your specific needs and discover how we can support your laboratory's success.

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- How does a hydraulic hot press machine work? Unlock Precision in Material Bonding and Forming

- What is a hydraulic hot press machine? A Guide to Force and Heat for Material Transformation

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production