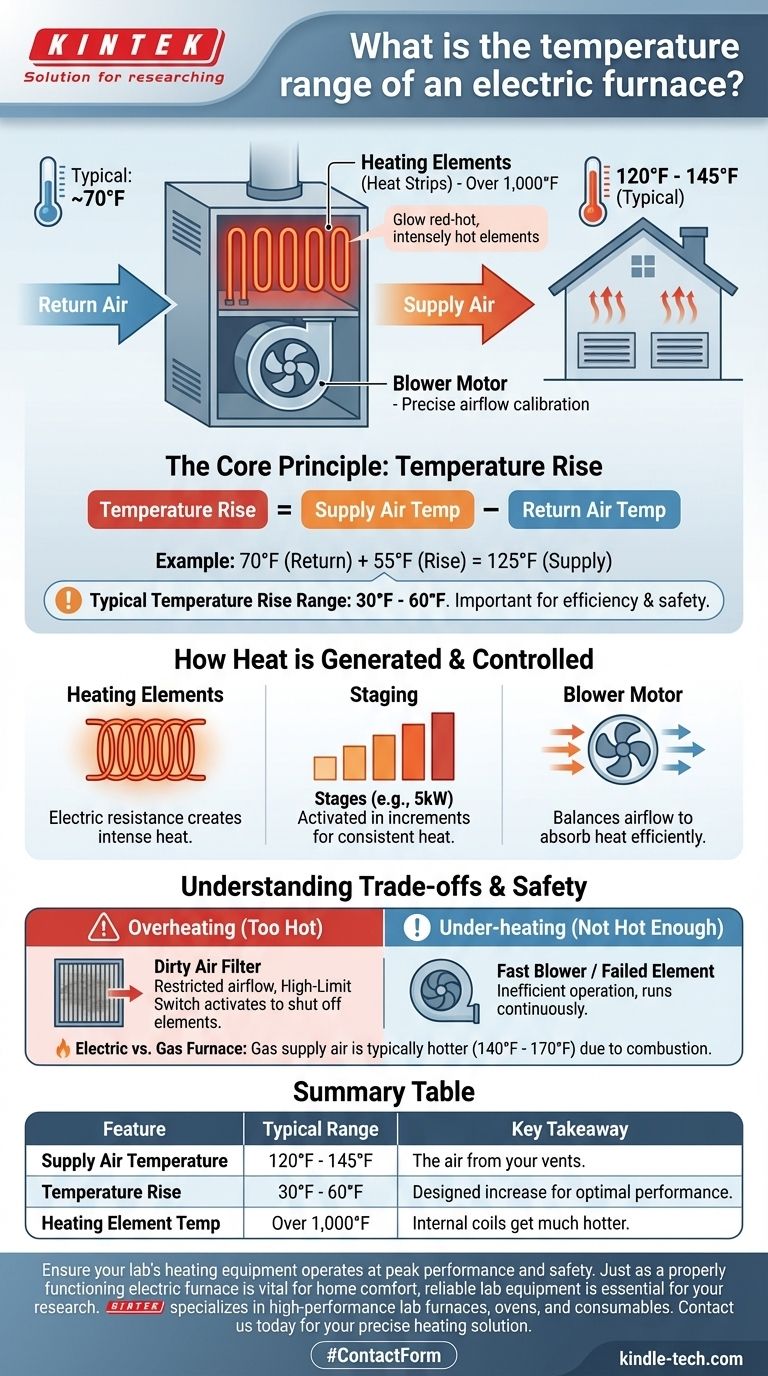

In short, an electric furnace typically heats the air circulating through your home to a temperature between 120°F and 145°F. This output temperature is not arbitrary; it's the result of a specific engineering principle known as "temperature rise," which measures how much the furnace heats the air from the moment it enters the unit to the moment it leaves.

The specific temperature of an electric furnace is less important than its temperature rise—the carefully controlled increase in temperature designed to balance heating effectiveness, energy efficiency, and operational safety.

The Core Principle: Temperature Rise

To truly understand your furnace's performance, you need to look past the single number of its output temperature and focus on the concept of temperature rise.

What is Temperature Rise?

Temperature rise is the difference between the temperature of the air entering the furnace (return air) and the air leaving it (supply air).

For example, if the air in your home is 70°F and your furnace has a temperature rise of 55°F, the air coming from your vents will be 125°F.

Why This Range is Important

Manufacturers design furnaces to operate within a specific temperature rise range, typically between 30°F and 60°F. This range ensures the system runs efficiently without overheating critical components.

Operating outside this specified range can damage the furnace and compromise safety.

Finding Your Furnace's Specified Range

Every furnace has a data plate (or rating plate) located inside the unit, usually in the blower or heat strip compartment. This plate lists the manufacturer's specified temperature rise range, which is the definitive guide for your specific model.

How an Electric Furnace Generates Heat

Unlike a gas furnace that relies on combustion, an electric furnace functions more like a powerful, enclosed hair dryer.

The Role of Heating Elements

An electric furnace uses large coils called heating elements or heat strips. When electricity passes through these coils, they glow red-hot, reaching temperatures well over 1,000°F.

The air from your home is then forced past these intensely hot elements, absorbing the heat before being distributed through your ductwork. The air itself never gets as hot as the elements.

Staging and Temperature Control

Most modern electric furnaces don't turn on all their heating elements at once. They are arranged in stages or banks, typically in 5-kilowatt (kW) increments.

The furnace activates only the number of stages needed to satisfy the thermostat's call for heat. This staged approach provides more consistent, comfortable heat and prevents large, inefficient swings in power consumption.

The Blower Motor's Critical Job

The furnace's performance is a partnership between the heating elements and the blower motor. The speed of the blower fan is precisely calibrated to the amount of heat being produced.

If the fan moves too slowly, the air will spend too much time passing over the elements and get dangerously hot. If it moves too quickly, the air won't absorb enough heat, leading to inefficient operation.

Understanding the Trade-offs and Safety Limits

Operating a furnace outside its designed temperature range introduces significant risks and inefficiencies.

The Dangers of Overheating

If the supply air temperature exceeds the manufacturer's specifications, the furnace is overheating. The most common cause is restricted airflow from a dirty air filter or blocked vents.

To prevent damage or fire, all electric furnaces are equipped with a high-limit switch. This safety device automatically shuts off the heating elements if internal temperatures exceed a preset limit, protecting the system from catastrophic failure.

The Inefficiency of Under-heating

If the supply air is not getting hot enough, the furnace is under-performing. This is often caused by a blower fan running too fast or a failed heating element.

An under-heating furnace will run continuously without ever satisfying the thermostat, wasting electricity and failing to keep your home comfortable.

Electric vs. Gas Furnace Temperatures

It's worth noting that gas furnaces typically produce slightly hotter supply air, often in the 140°F to 170°F range. This is simply due to the nature of combustion, which is a more intense heat-generating process than electrical resistance.

Is Your Furnace Operating Correctly?

You can use this knowledge to ensure your system is running safely and efficiently.

- If you're concerned about performance: You can check the temperature rise yourself with two thermometers—one at a return grille and one at a supply vent. If the difference is far outside the range listed on your furnace's data plate, it's time to call a professional.

- If your furnace feels like it's not heating enough: The very first thing to check is your air filter. A clogged filter is the most common cause of almost all furnace performance issues.

- If you're choosing a new system: Focus on correct sizing and professional installation. Any modern electric furnace will be designed to operate within the safe and effective temperature rise range; proper airflow is what makes it work in your home.

Understanding your furnace's temperature range empowers you to gauge its health, ensure its safety, and maintain an efficient, comfortable home.

Summary Table:

| Feature | Typical Range | Key Takeaway |

|---|---|---|

| Supply Air Temperature | 120°F - 145°F | The air coming from your vents. |

| Temperature Rise | 30°F - 60°F | The designed increase in air temperature for optimal performance. |

| Heating Element Temp | Over 1,000°F | The internal coils get much hotter than the air. |

Ensure your lab's heating equipment operates at peak performance and safety. Just as a properly functioning electric furnace is vital for home comfort, reliable and precise lab equipment is essential for your research and testing. KINTEK specializes in high-performance lab furnaces, ovens, and consumables, delivering the precise temperature control and durability your laboratory demands. Contact us today to find the perfect heating solution for your specific application and ensure your lab operates efficiently and safely.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is the difference between sintering and fusion? Solid-State vs. Liquid-Phase Processing Explained

- What is the process of vacuum tempering? Achieve a Perfect Balance of Hardness and Toughness

- What are the mechanisms of sintering process? Unlock Stronger, Denser Materials

- How does the cooling rate control of a furnace influence slow-cooled solid-state electrolytes? Achieve Crystal Perfection

- What core function does a high-temperature sintering furnace serve? Optimize All-Ceramic Composite Cathode Production

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance

- What temperature does tungsten carbide sinter at? Master the 1350°C-1500°C Liquid-Phase Sintering Process

- What is the purpose of using a vacuum drying oven for TiS2 composite cathodes? Ensure Purity in Solid-State Batteries