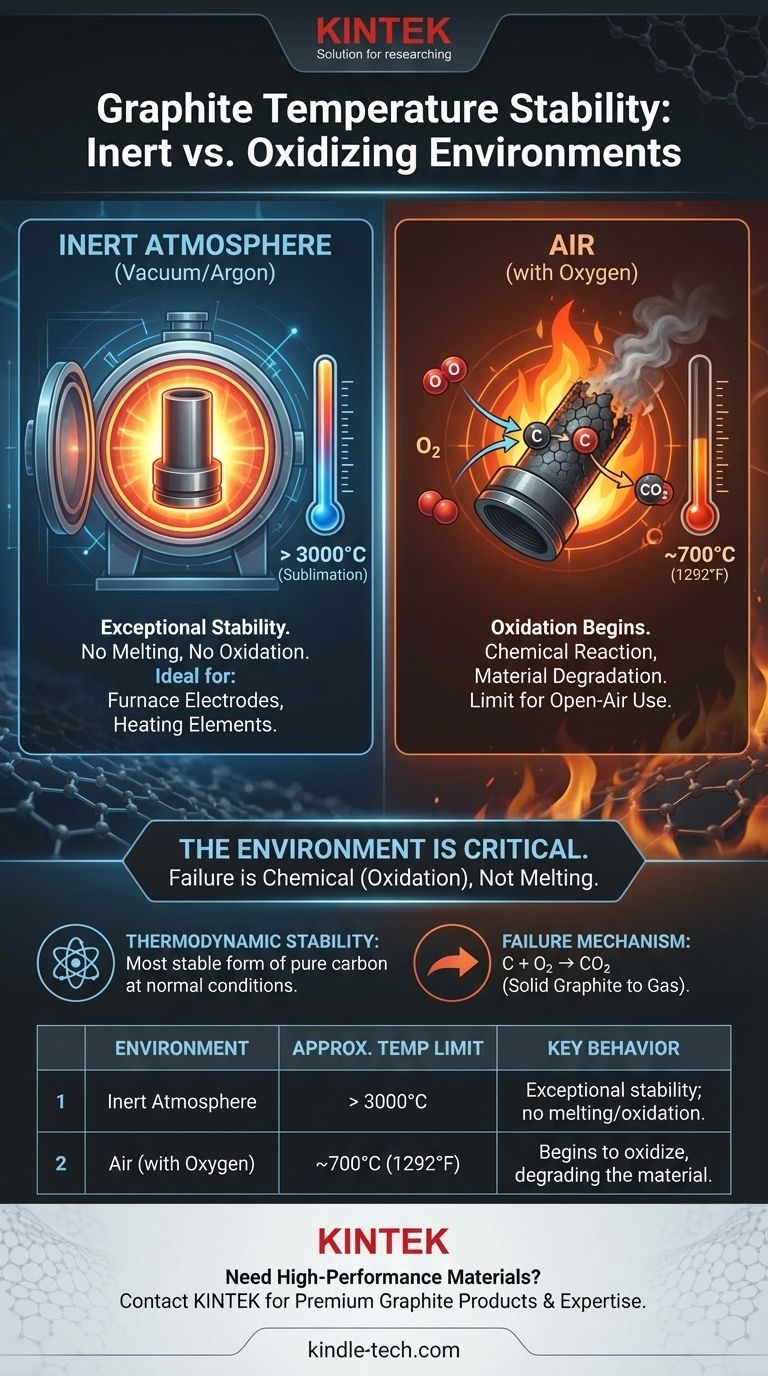

In short, graphite's temperature stability is exceptional but entirely dependent on its environment. While it remains stable at thousands of degrees in an inert atmosphere, it begins to oxidize and degrade in the presence of oxygen at temperatures starting around 700°C (1292°F).

The defining limit of graphite's temperature stability is not a melting point, but a chemical reaction. Its remarkable performance at extreme temperatures is only achievable in oxygen-free environments like a vacuum or inert gas.

The Two Conditions of Graphite Stability

Graphite does not have a single failure temperature. Its performance ceiling is dictated by the chemical environment, creating two vastly different scenarios for its use.

Stability in an Inert Atmosphere

In an oxygen-free (inert) environment, such as a vacuum or argon-filled furnace, graphite's thermal stability is extraordinary. It is one of the most heat-resistant materials known.

This property makes it a premier choice for high-temperature applications like furnace electrodes, heating elements, and refractory linings where oxygen can be excluded.

The Oxidation Limit in Air

In the presence of oxygen, graphite's stability is significantly reduced. It begins to react with oxygen—a process known as oxidation—at approximately 700°C.

This chemical reaction converts the solid graphite into carbon dioxide gas (C + O₂ → CO₂), causing the material to degrade and lose mass. This is the practical temperature limit for using graphite in open-air applications.

Why Environment is the Critical Factor

Understanding the underlying principles explains why the atmosphere is the most important variable.

Failure is a Chemical Reaction, Not Melting

The failure of graphite in air is not a physical change like melting. It is a chemical change. The carbon atoms are stripped away by oxygen, fundamentally breaking the material down.

At standard pressure, graphite does not melt. Instead, it sublimes (turns directly from a solid to a gas) at an extremely high temperature, well over 3000°C. However, oxidation occurs at a much lower temperature, making it the more common and pressing limitation.

Fundamental Thermodynamic Stability

Under normal conditions (298 K and 1 atm), graphite is the most stable form of pure carbon. It is thermodynamically more stable than diamond, though the energy difference is small.

This inherent stability is what allows it to withstand extreme heat, provided it is protected from chemically reactive elements like oxygen.

Making the Right Choice for Your Application

To use graphite effectively, you must match its properties to the operational environment.

- If your primary focus is high-temperature use in open air: Graphite is not suitable for sustained use above 700°C, as oxidation will cause rapid degradation.

- If your primary focus is performance in a vacuum or inert gas: Graphite is an exceptional choice, maintaining its structural integrity at temperatures far exceeding those of most metals and ceramics.

Ultimately, harnessing graphite's power requires controlling its atmosphere.

Summary Table:

| Environment | Approximate Temperature Limit | Key Behavior |

|---|---|---|

| Inert Atmosphere (Vacuum/Argon) | > 3000°C (Sublimation Point) | Exceptional stability; no melting or oxidation |

| Air (with Oxygen) | ~700°C (1292°F) | Begins to oxidize, degrading the material |

Need a high-performance material for your extreme-temperature application?

At KINTEK, we specialize in premium lab equipment and consumables, including high-purity graphite products designed for superior performance in controlled environments. Whether you're operating a vacuum furnace or require custom graphite components, our expertise ensures you get the right material for your specific thermal and atmospheric conditions.

Let our specialists help you harness the full potential of graphite. Contact us today to discuss your laboratory needs!

Visual Guide

Related Products

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the best solvent for FTIR? Master Solvent Selection for Clear, Accurate Spectra

- What is the necessity of using a laboratory drying oven for Mo-Ti-N catalysts? Protect Your Porous Architecture

- What is the process of sputter coating? A Step-by-Step Guide to Thin Film Deposition

- What is the function of a drying oven in ZrB2-SiC processing? Ensure Defect-Free Ceramic Sintering

- What is the role of an ultrasonic cleaner during magnesium alloy coating? Ensure Superior Adhesion and Surface Purity

- What is a microwave pyrolysis reactor? A Guide to Faster, More Efficient Thermal Processing

- What does FTIR read? Unlocking Molecular Fingerprints with Infrared Spectroscopy

- What are the advantages of the sintering process? Achieve Cost-Effective, Complex Parts