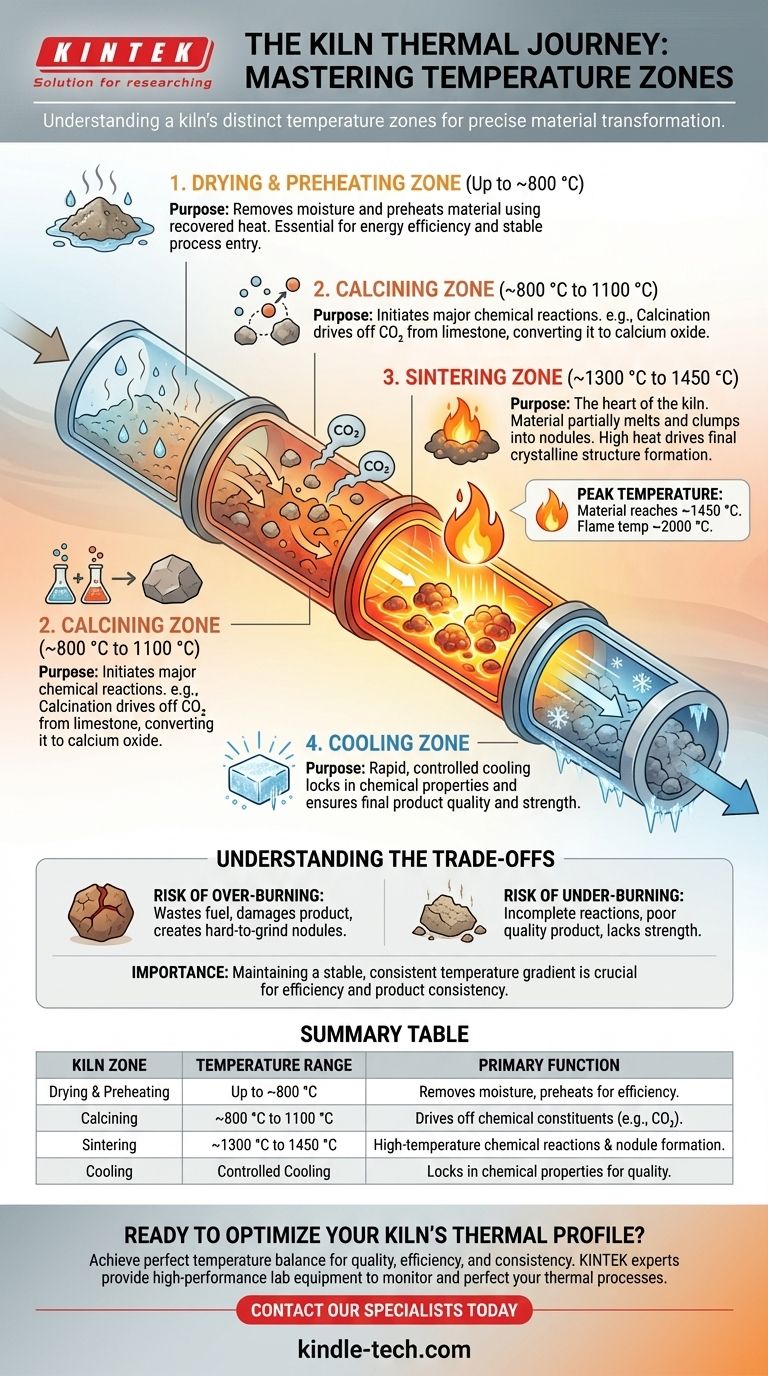

In short, a kiln doesn't have a single temperature. Instead, it is divided into a series of distinct temperature zones, each designed to perform a specific chemical or physical transformation on the material passing through it. These zones typically include a preheating zone, a calcining zone, a high-temperature sintering (or burning) zone, and a cooling zone.

The concept of "temperature zones" is fundamental to understanding a kiln's function. It's not just about heat; it's about a precisely controlled thermal journey that transforms raw materials into a finished product with specific properties.

The Journey Through the Kiln: A Zone-by-Zone Breakdown

A rotary kiln operates as a continuous process. Raw material enters one end, travels through progressively hotter zones, and exits the other end as a transformed product. Each zone has a critical function.

The Drying and Preheating Zone (Up to ~800 °C)

The first stage of the journey is about preparation. As raw material enters the kiln, this initial zone uses recovered heat from hotter sections to drive off any free water.

Its primary purpose is to remove moisture and begin raising the material's temperature, ensuring it enters the next stage in a stable, prepared state. This step is crucial for energy efficiency.

The Calcining Zone (~800 °C to 1100 °C)

Once preheated, the material enters the calcining zone. Here, the temperature is high enough to initiate the first major chemical reaction.

For materials like limestone (calcium carbonate), this is where calcination occurs, driving off carbon dioxide (CO2) and converting it into calcium oxide. This is an essential step in processes like cement manufacturing.

The Sintering Zone (~1300 °C to 1450 °C)

This is the heart of the kiln and the point of maximum temperature. The material, now chemically prepared, is heated to the point of incipient fusion, where it begins to partially melt and clump together into nodules.

As the provided data notes, material temperatures here can reach 1450 °C. To achieve this, the flame temperature from the kiln's burner must be significantly higher, often around 2000 °C. This intense heat drives the final chemical reactions that form the desired crystalline structures in the final product, such as cement clinker.

The Cooling Zone

After leaving the intense heat of the sintering zone, the material must be cooled rapidly. This is not a passive process; it's a controlled stage that locks in the chemical properties created in the sintering zone.

Proper cooling is critical for product quality. For example, in cement production, rapid cooling prevents the newly formed compounds from decomposing, ensuring the final product has the required strength.

Understanding the Trade-offs

Achieving the perfect temperature profile across these zones is a delicate balancing act. Deviations can significantly impact both product quality and operational efficiency.

The Risk of Over-burning

Exceeding the target temperature in the sintering zone wastes an enormous amount of fuel. It can also damage the final product by creating overly large, hard nodules that are difficult to grind.

The Problem of Under-burning

Failing to reach the necessary sintering temperature results in incomplete chemical reactions. This produces a poor-quality product that lacks the required chemical composition and physical strength.

The Importance of a Stable Profile

The most critical factor is not just hitting peak temperature, but maintaining a stable and consistent temperature gradient across all zones. Fluctuations can lead to inefficient reactions and an inconsistent final product.

Making the Right Choice for Your Goal

The specific temperature profile you need depends entirely on the material being processed and your desired outcome.

- If your primary focus is creating high-quality cement clinker: Your critical objective is maintaining a stable material temperature of around 1450 °C in the sintering zone.

- If your primary focus is energy efficiency: You must optimize heat recovery from the cooling zone to be used in the drying and preheating zone.

- If your primary focus is consistent product quality: The key is maintaining a smooth, stable, and repeatable temperature curve through all four zones of the kiln.

Ultimately, mastering the temperature zones is essential for controlling the final properties of the material you produce.

Summary Table:

| Kiln Zone | Temperature Range | Primary Function |

|---|---|---|

| Drying & Preheating | Up to ~800 °C | Removes moisture and preheats material for energy efficiency. |

| Calcining | ~800 °C to 1100 °C | Drives off chemical constituents (e.g., CO2 from limestone). |

| Sintering | ~1300 °C to 1450 °C | The high-temperature heart where final chemical reactions and nodule formation occur. |

| Cooling | Controlled Cooling | Locks in chemical properties and ensures product quality. |

Ready to Optimize Your Kiln's Thermal Profile?

Achieving the perfect temperature balance is critical for product quality, energy efficiency, and process consistency. The experts at KINTEK are here to help. We specialize in providing the high-performance lab equipment and consumables you need to monitor, control, and perfect your thermal processes.

Contact our specialists today to discuss how our solutions can help you master the thermal journey in your kiln and achieve superior results.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing