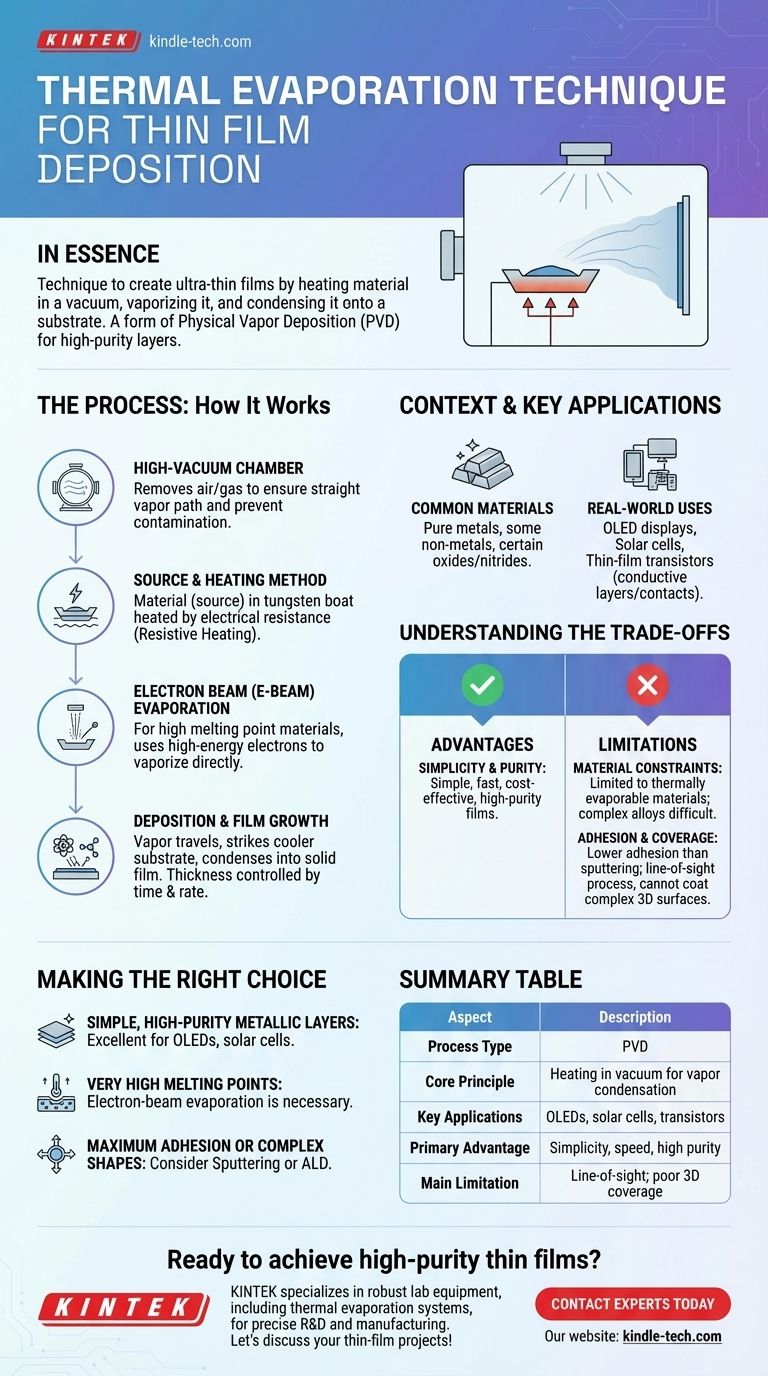

In essence, thermal evaporation is a technique used to create ultra-thin films by heating a material inside a vacuum until it turns into a vapor. This vapor then travels and condenses onto a cooler surface, known as a substrate, forming a uniform, solid coating. It is a straightforward and widely used form of Physical Vapor Deposition (PVD), valued for its simplicity and ability to deposit high-purity layers.

At its core, thermal evaporation is the process of "boiling" a source material in a vacuum so its vapor can coat a target. Its effectiveness comes from this direct, physical transfer, but this same simplicity introduces specific limitations on the types of materials and structures it can create.

How Thermal Evaporation Works: The Process

Thermal evaporation is a line-of-sight deposition process that relies on a few fundamental steps executed within a controlled environment.

The Critical Role of the Vacuum

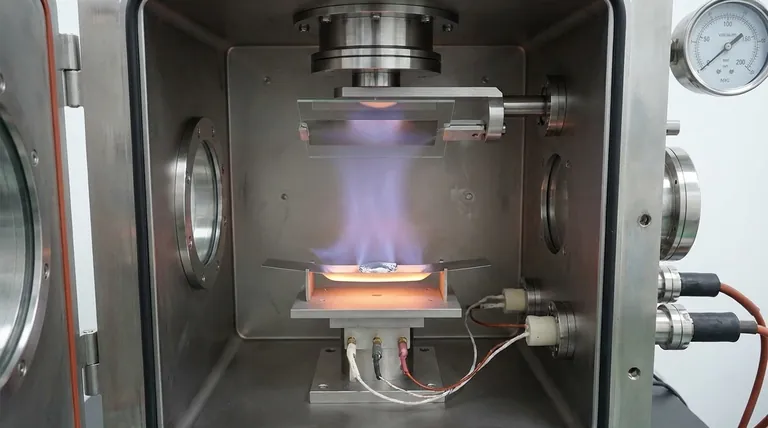

First, the source material and the substrate are placed inside a high-vacuum chamber. This vacuum is essential because it removes air and other gas particles.

Without a vacuum, the vaporized material atoms would collide with air molecules, preventing them from reaching the substrate in a straight, predictable path and potentially contaminating the final film.

The Source and Heating Method

The material to be deposited, known as the source, is placed in a container often called a "boat" or "crucible." This boat is made from a material with a very high melting point, such as tungsten.

An electric current is then passed through the boat, causing it to heat up due to electrical resistance. This is known as resistive heating. The heat transfers to the source material, causing it to melt and then evaporate, releasing a vapor of atoms or molecules.

An Alternative: Electron Beam Evaporation

For materials with extremely high melting points, an alternative method called electron beam (e-beam) evaporation is used. Instead of a heated boat, a high-energy beam of electrons is aimed directly at the source material, heating it to vaporization.

Deposition and Film Growth

The vaporized atoms travel through the vacuum chamber and strike the cooler substrate. Upon impact, they lose their thermal energy, condense back into a solid, and stick to the surface.

Over time, these condensed atoms build up, forming a continuous thin film. The thickness of this film is controlled by managing the deposition time and the rate of evaporation.

Context and Key Applications

Thermal evaporation is a sub-category of Physical Vapor Deposition (PVD), a class of techniques that deposit films through purely physical means, as opposed to the chemical reactions used in Chemical Vapor Deposition (CVD).

Common Materials

This technique excels at depositing pure materials that evaporate cleanly without decomposing. This includes many pure metals and some non-metals. It can also be used for certain molecular compounds like oxides and nitrides.

Real-World Uses

Because of its ability to create high-quality conductive layers, thermal evaporation is crucial for manufacturing a range of electronic devices.

Key applications include creating the metallic contacts and layers in OLED displays, solar cells, and thin-film transistors.

Understanding the Trade-offs

No single deposition technique is perfect for every scenario. The strengths of thermal evaporation are directly tied to its limitations.

The Advantage: Simplicity and Purity

Thermal evaporation is a relatively simple, fast, and cost-effective deposition method. Because it doesn't rely on complex chemical precursors, it is excellent for creating films of very high purity.

The Limitation: Material Constraints

The process is limited to materials that can be thermally evaporated. Complex alloys are difficult to deposit because their constituent elements often have different evaporation rates, leading to a film composition that doesn't match the source material.

The Limitation: Adhesion and Coverage

Films deposited via thermal evaporation typically have lower adhesion to the substrate compared to those from higher-energy processes like sputtering. Furthermore, because it is a "line-of-sight" technique, it cannot easily coat complex, three-dimensional surfaces, as any non-visible area will be left uncoated in a "shadow."

Making the Right Choice for Your Goal

Selecting a deposition technique requires matching the process capabilities to your desired outcome.

- If your primary focus is creating simple, high-purity metallic layers: Thermal evaporation is an excellent, cost-effective choice, especially for applications like electrical contacts in OLEDs or solar cells.

- If your primary focus is depositing materials with very high melting points: Electron-beam evaporation, a more powerful variant of this technique, is the necessary approach.

- If your primary focus is achieving maximum film adhesion or coating complex shapes: You should consider alternative PVD methods like magnetron sputtering or other techniques like Atomic Layer Deposition (ALD).

By understanding these core principles, you can confidently determine when thermal evaporation is the optimal tool for producing your thin film.

Summary Table:

| Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Heating a material in a vacuum to create a vapor that condenses on a substrate. |

| Key Applications | OLED displays, solar cells, thin-film transistors. |

| Primary Advantage | Simplicity, speed, and ability to create high-purity films. |

| Main Limitation | Line-of-sight process; cannot easily coat complex 3D surfaces. |

Ready to achieve high-purity thin films for your research or production?

KINTEK specializes in providing robust and reliable lab equipment, including thermal evaporation systems, to meet the precise demands of laboratories and manufacturers. Whether you are developing next-generation OLED displays or advanced solar cells, our expertise ensures you have the right tools for optimal deposition results.

Let's discuss how we can support your thin-film projects. Contact our experts today to find the perfect solution for your application!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Evaporation Boat for Organic Matter

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab