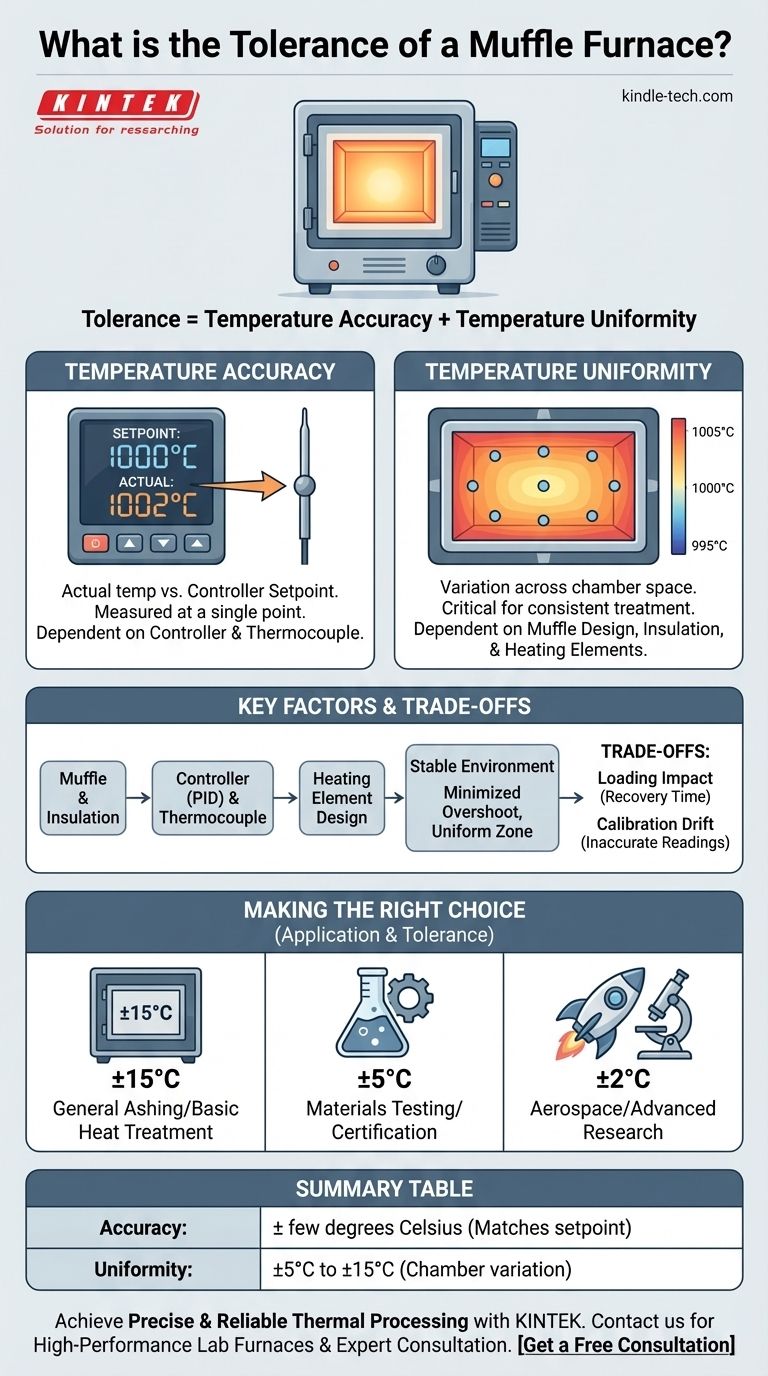

The "tolerance" of a muffle furnace is not a single value but is defined by two key performance metrics: temperature accuracy and temperature uniformity. While there is no universal standard, a typical laboratory muffle furnace may have a temperature accuracy of a few degrees and a uniformity of ±5°C to ±15°C, but this varies significantly based on the furnace's design, controller, and intended application.

The core issue is not the furnace's maximum temperature, but its ability to maintain a stable and consistent temperature throughout its entire heating chamber. Understanding the difference between accuracy and uniformity is critical to achieving reliable and repeatable results for any thermal process.

Deconstructing "Tolerance": Accuracy vs. Uniformity

When discussing furnace performance, the term "tolerance" is too broad. To properly evaluate a furnace, we must distinguish between two separate, crucial metrics.

Defining Temperature Accuracy

Temperature accuracy measures how closely the actual temperature inside the chamber matches the setpoint on the controller.

It is typically measured at a single point, usually near the furnace's primary thermocouple. A high-quality controller and a properly calibrated thermocouple are the most critical factors for ensuring accuracy.

Defining Temperature Uniformity

Temperature uniformity measures the variation in temperature across different points within the usable chamber space at a specific temperature.

For many applications, such as annealing or materials testing, this is the more important metric. A furnace can be accurate at one point but have significant hot and cold spots, leading to inconsistent treatment of the workpiece.

What Determines a Furnace's Performance?

A furnace's ability to hold a tight tolerance is not accidental; it is a direct result of its engineering and components.

The Muffle and Insulation

The core component is the refractory-lined chamber, known as the "muffle." This chamber serves two purposes: it insulates the workload from direct contact with the heating elements and isolates it from contaminants.

High-quality insulation prevents heat loss and helps create a stable, homogeneous thermal environment, which is the foundation of good uniformity.

The Controller and Thermocouple

The controller is the brain of the furnace. Modern digital PID (Proportional-Integral-Derivative) controllers are far more sophisticated than older analog models.

They continuously monitor the thermocouple and modulate power to the heating elements to minimize temperature overshoots and maintain a stable setpoint, directly improving accuracy.

Heating Element Design

The placement and quality of heating elements are critical for uniformity. Furnaces with elements on multiple sides (e.g., three or four walls) will generally provide a more uniform heating zone than those with elements only on two sides.

Understanding the Trade-offs

Choosing or operating a furnace requires understanding the practical limitations that affect its real-world performance.

Confusing Setpoint with Chamber Reality

The temperature displayed on the controller is only the temperature at the tip of the control thermocouple. It does not guarantee the same temperature exists throughout the entire chamber.

For precise work, a temperature uniformity survey using multiple thermocouples is often necessary to map the actual thermal profile of the furnace.

The Impact of Loading

Placing a large or dense workload into a hot furnace will create a significant, temporary cold spot. The furnace's recovery time—how quickly it can stabilize back to the setpoint with good uniformity—is a key performance characteristic.

Neglecting Calibration

Over time, thermocouples can "drift," providing inaccurate readings to the controller. A furnace that is not regularly calibrated cannot be trusted for any process that requires thermal precision. An uncalibrated furnace provides unreliable and non-repeatable results.

Making the Right Choice for Your Goal

To select the appropriate furnace, you must match its performance capabilities to the requirements of your specific application.

- If your primary focus is general ashing or basic heat treatment: A standard furnace with typical uniformity (e.g., ±15°C) is often sufficient and cost-effective.

- If your primary focus is materials testing or process certification: You require a furnace with a specified, and preferably certified, temperature uniformity of ±5°C or better.

- If your primary focus is aerospace component annealing or advanced research: You need a high-performance model with tight uniformity (e.g., ±2°C), advanced programmable controllers, and possibly multi-zone heating.

Ultimately, choosing the right muffle furnace means looking beyond the maximum temperature and focusing on the validated precision required for your process.

Summary Table:

| Performance Metric | Definition | Typical Range (Lab Furnace) |

|---|---|---|

| Temperature Accuracy | How closely the actual temperature matches the controller setpoint. | ± few degrees Celsius |

| Temperature Uniformity | The temperature variation across the entire chamber at a set temperature. | ±5°C to ±15°C (varies by model) |

Achieve precise and reliable thermal processing with KINTEK.

Understanding the true tolerance of your muffle furnace is critical for repeatable results in ashing, heat treatment, and materials testing. Don't let inaccurate temperatures or poor uniformity compromise your work.

KINTEK specializes in high-performance lab furnaces engineered for superior temperature control and chamber uniformity. Our experts will help you select the right equipment—from cost-effective standard models to high-precision systems certified for critical applications—ensuring your process is reliable and validated.

Contact us today to discuss your specific thermal processing requirements and find the perfect furnace solution for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role does a high-temperature furnace play in producing OMA? Master Precision Calcination for Pure Mesoporous Alumina

- What is the role of muffle furnace in fluid mechanics? A Key Tool for Material Preparation

- What is a box furnace? A Guide to Batch Thermal Processing for Labs & Industry

- How do high-precision high-temperature furnaces assist in biochar-cement compatibility? Optimize Hydration & Strength

- What is the critical role of a high-temperature furnace in the synthesis of NASICON? Ensure Pure Crystal Formation.

- What role do laboratory box resistance furnaces play in simulating the effects of radionuclide decay heat? | KINTEK

- What is a muffle furnace for laboratory use? A Guide to Contaminant-Free High-Temperature Processing

- Why is the annealing treatment in a high-temperature muffle furnace critical for the preparation of an Sb-SnO2 interlayer?