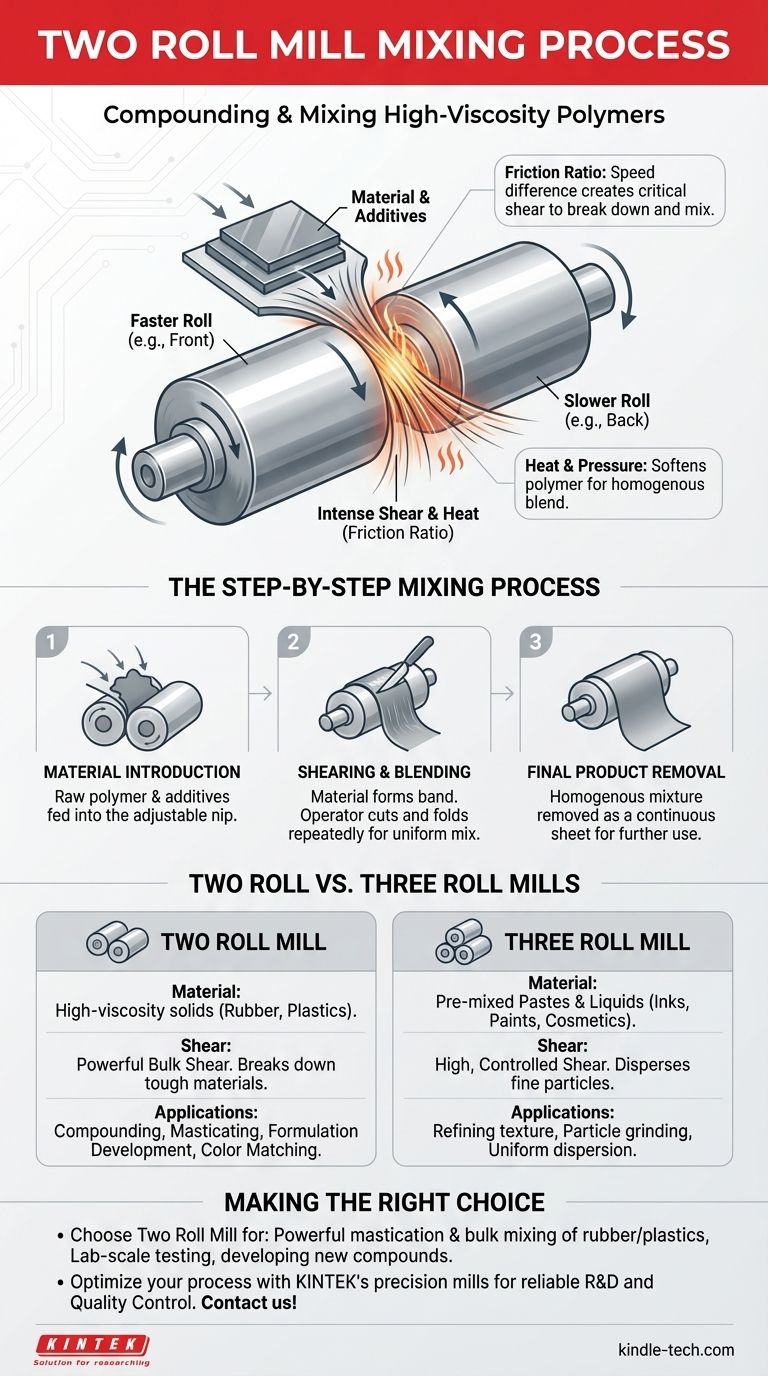

At its core, the two roll mill mixing process is a method used to compound, mix, or break down polymers like rubber and plastics. It operates by passing the material through the gap between two counter-rotating horizontal rolls, subjecting it to intense pressure and shear forces to achieve a homogenous blend.

The effectiveness of a two roll mill hinges on a principle called friction ratio—the difference in speed between the two rolls. This speed differential is what generates the critical shearing action required to break down and intimately mix high-viscosity materials.

How a Two Roll Mill Achieves Mixing

To understand the process, we must first look at its fundamental mechanics. The design is simple, but the forces it generates are powerful and precise.

The Core Components: Rolls and Nip

A two roll mill consists of two durable, hollow metal cylinders positioned horizontally. These rolls rotate towards each other.

The adjustable gap between these two rolls is the most critical parameter, known as the nip. By controlling the size of the nip, an operator dictates the amount of pressure applied to the material.

The Principle of Shear: Friction Ratio

The rolls do not rotate at the same speed. This intentional speed difference is called the friction ratio.

As material is pulled into the nip, the faster roll pulls it forward while the slower roll provides resistance. This action creates an intense shearing force, effectively tearing and smearing the material layers against one another, which is essential for breaking down polymer chains and dispersing additives.

The Role of Heat and Pressure

The mechanical work of shearing and compression generates significant heat. This heat helps to soften, or masticate, the polymer, making it more pliable and receptive to mixing with other ingredients like pigments, fillers, or curing agents.

The Step-by-Step Mixing Process

The operator's technique is crucial for achieving a uniform mixture. The process is both a science and a craft.

Material Introduction

The raw polymer, often in the form of a solid slab or pellets, is fed into the nip along with any additives. The powerful rolls immediately begin pulling the material through the gap.

Shearing and Blending

After passing through the nip, the softened material tends to stick to and form a continuous band around the faster-moving roll.

The operator then uses a blade to cut this band and fold it back into the nip. This process of cutting, folding, and re-introducing the material is repeated continuously to ensure all parts of the batch are evenly processed and a homogenous mixture is achieved.

Final Product Removal

Once mixing is complete, the material is typically cut from the roll in a continuous sheet. This final sheet can then be used for further processing, such as molding, or for quality control testing.

Understanding the Trade-offs: Two Roll vs. Three Roll Mills

While their names are similar, two roll and three roll mills are designed for fundamentally different tasks and materials.

Material Type and Viscosity

Two roll mills excel at processing very high-viscosity solids. They are the standard for masticating raw rubber and compounding it with reinforcing fillers, a process that requires immense force to break down and blend.

Three roll mills, in contrast, are used for dispersing fine solid particles within a liquid or paste that is already pre-mixed. They are not designed to break down tough solids but to refine the texture of viscous liquids like inks, paints, cosmetics, and chocolate.

The Nature of Shear

A two roll mill provides powerful bulk shear designed to break down and homogenize large batches of tough material.

A three roll mill uses progressively smaller gaps and increasing roll speeds to create exceptionally high, controlled shear. This action finely grinds particles and ensures a smooth, uniform dispersion in a liquid base, which is measured in microns.

Common Applications

The two roll mill is a workhorse in the rubber and plastics industries for formulation development, color matching, and quality control.

The three roll mill is essential in industries where final product texture is critical, such as manufacturing high-quality printing inks, pharmaceuticals, and cosmetics.

Making the Right Choice for Your Application

Selecting the correct mill is determined entirely by your starting material and your desired final product.

- If your primary focus is compounding raw polymers like rubber or plastics: The two roll mill is the standard choice for its powerful mastication and bulk mixing capabilities.

- If your primary focus is dispersing fine particles in a viscous liquid or paste: The three roll mill offers the superior control and high shear needed to achieve a homogenous, finely-ground final product.

- If your primary focus is lab-scale material testing and polymer formulation: The two roll mill is an indispensable tool for quality control and developing new compounds from raw materials.

Understanding these core mechanical principles empowers you to select the precise tool for your material processing needs.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Use | Compounding, masticating, and mixing high-viscosity polymers (rubber, plastics). |

| Core Principle | Friction ratio (differential roll speed) generates intense shear forces. |

| Key Component | Adjustable nip (gap) between two counter-rotating rolls. |

| Ideal For | Lab-scale testing, formulation development, and quality control. |

Ready to optimize your polymer compounding and mixing processes? KINTEK's two roll mills are engineered for precision and durability, delivering the high-shear action essential for developing and testing rubber, plastic, and other polymer compounds in your lab. Our equipment ensures consistent, homogenous batches for reliable R&D and quality control results. Contact our experts today to find the perfect mill for your application!

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Single Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- Is co-extrusion the same as dual extrusion? Unlock the Power of Multi-Material Plastic Profiles

- How many types of rolling mills are there? A Guide to Roll Configurations & Capabilities

- What is the function of mixing mill? Achieve Perfectly Blended Rubber & Polymer Compounds

- What is an internal batch mixer? Achieve Superior Mixing for Rubber & Plastics

- What is the disadvantage of a two-roll mill? Limited Thickness Reduction Due to Roll Flattening

- What is the difference between two-high and three high rolling mills? Boost Your Metal Rolling Efficiency

- How profitable is injection molding? Unlock High-Volume Manufacturing Profitability

- Why is a roller press machine required for CuMH solid-state membranes? Expert Insights on Flexible Electrolyte Forming