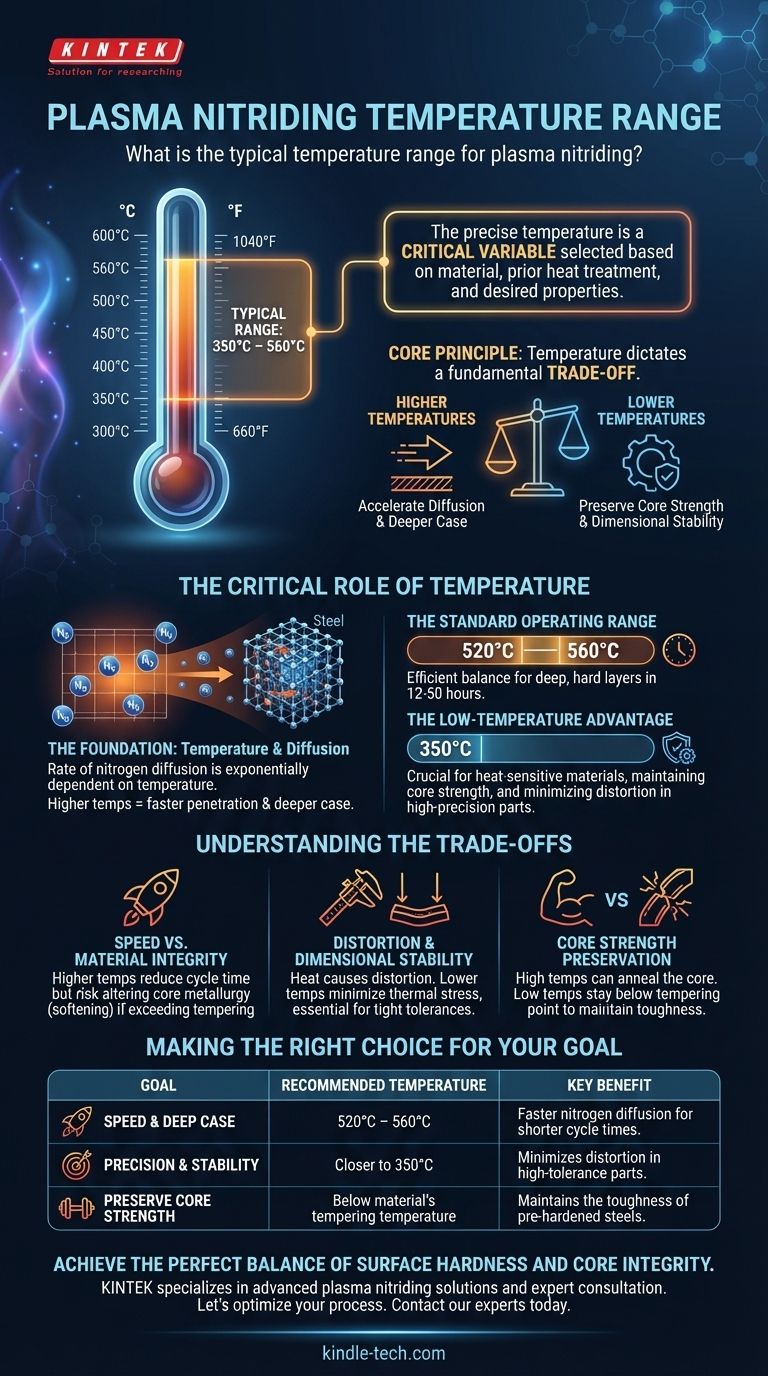

In plasma nitriding, the typical temperature range is between 350°C and 560°C (approximately 660°F to 1040°F). This broad range exists because the precise temperature is not a fixed number but a critical variable selected based on the specific material being treated, its prior heat treatment, and the desired final properties of the surface layer.

The core principle to understand is that temperature in plasma nitriding dictates a fundamental trade-off: higher temperatures accelerate the nitrogen diffusion process for a deeper case, while lower temperatures are essential for preserving the core strength and dimensional stability of precision components.

The Critical Role of Temperature

Temperature is the single most influential factor in the plasma nitriding process. It directly controls the speed of the reaction and the resulting metallurgical structure of the workpiece.

The Foundation: Temperature and Diffusion

The rate at which nitrogen atoms diffuse into the surface of the steel is exponentially dependent on temperature.

Higher temperatures provide more thermal energy, allowing nitrogen to penetrate the material faster and deeper. This directly impacts the total cycle time required to achieve a specific case depth.

The Standard Operating Range

For many common applications involving ferrous materials, a range of 520°C to 560°C is used.

This temperature band offers an efficient balance, enabling the formation of a sufficiently deep and hard nitrided layer within a practical timeframe, often between 12 and 50 hours.

The Low-Temperature Advantage

Specialized low-temperature plasma nitriding can be performed at temperatures as low as 350°C.

This approach is specifically chosen for materials that are sensitive to heat. It is critical for maintaining the high core strength of previously hardened and tempered steels and for minimizing any risk of distortion in high-precision parts.

Understanding the Trade-offs

Selecting the right temperature is not about finding one "best" number; it's about balancing competing objectives to achieve the desired outcome for a specific component.

Speed vs. Material Integrity

The primary trade-off is between processing speed and the preservation of the material's underlying properties.

While a higher temperature significantly reduces the required cycle time, it can also alter the core metallurgy of the part, potentially softening it if the nitriding temperature exceeds the material's original tempering temperature.

Distortion and Dimensional Stability

Heat is a primary cause of distortion in metal components. For parts with tight tolerances, such as gears, dies, and injectors, maintaining dimensional stability is non-negotiable.

Using a lower nitriding temperature minimizes thermal stress and dramatically reduces the risk of warping or size changes, ensuring the finished part meets its design specifications.

Core Strength Preservation

Many components, like crankshafts and forging dies, rely on a combination of a hard, wear-resistant surface and a strong, tough core.

If the nitriding temperature is too high, it can anneal or soften the core material, compromising the part's overall strength and fatigue resistance. Low-temperature nitriding avoids this by staying below the critical tempering point of the steel.

Making the Right Choice for Your Goal

The optimal temperature is dictated entirely by the application's end goal. Use the following guidelines to inform your decision.

- If your primary focus is speed and achieving a deep case depth: A temperature in the higher range (520°C – 560°C) is appropriate, provided the component's material properties and dimensional tolerances can withstand it.

- If your primary focus is dimensional stability for precision parts: A lower temperature process (closer to 350°C) is the superior choice to eliminate the risk of distortion.

- If you are treating pre-hardened or tempered tool steels: You must select a temperature below the material's final tempering temperature to preserve its crucial core strength.

Mastering temperature control allows you to tailor the plasma nitriding process to enhance any component with precision and reliability.

Summary Table:

| Goal | Recommended Temperature Range | Key Benefit |

|---|---|---|

| Speed & Deep Case | 520°C – 560°C | Faster nitrogen diffusion for shorter cycle times. |

| Precision & Stability | Closer to 350°C | Minimizes distortion in high-tolerance parts. |

| Preserve Core Strength | Below material's tempering temperature | Maintains the toughness of pre-hardened steels. |

Achieve the perfect balance of surface hardness and core integrity for your components.

At KINTEK, we specialize in providing advanced plasma nitriding solutions and expert consultation for laboratories and manufacturers. Whether you're processing tool steels, precision gears, or high-performance components, our expertise ensures your materials meet exact specifications for wear resistance, fatigue life, and dimensional stability.

Let's optimize your process. Contact our experts today to discuss how we can help you select the ideal parameters for your specific application.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the advantages and disadvantages of annealing? A Guide to Strategic Material Processing

- What is the temperature of pyrolysis? A Guide to Controlling Product Yields

- What materials are used in an electric arc furnace? A Guide to Scrap, Electrodes & Refractories

- What are the variables of the sintering process? Master Temperature, Time, Pressure & Atmosphere

- What is fast pyrolysis of waste biomass? Converting Biomass to Bio-Oil in Seconds

- What are the techniques of quenching? Master Rapid Cooling for Hardness and Durability

- What is the primary function of an Industrial Drying Oven in titanium-magnesium waste processing? Ensure Data Precision

- What are the applications of vacuum deposition? Create High-Performance Coatings for Your Products