At its core, a biomass pellet machine is a device that transforms low-density, raw organic materials into dense, uniform pellets. It accomplishes this by forcing the material through a die under immense pressure. The primary uses for these pellets fall into three main categories: creating renewable fuel, producing balanced animal feed, and manufacturing absorbent animal bedding.

The fundamental purpose of a pellet machine is not just waste disposal, but value creation. It solves the logistical problems of handling bulky biomass by converting it into a dense, storable, and easily transportable commodity for energy, feed, or other applications.

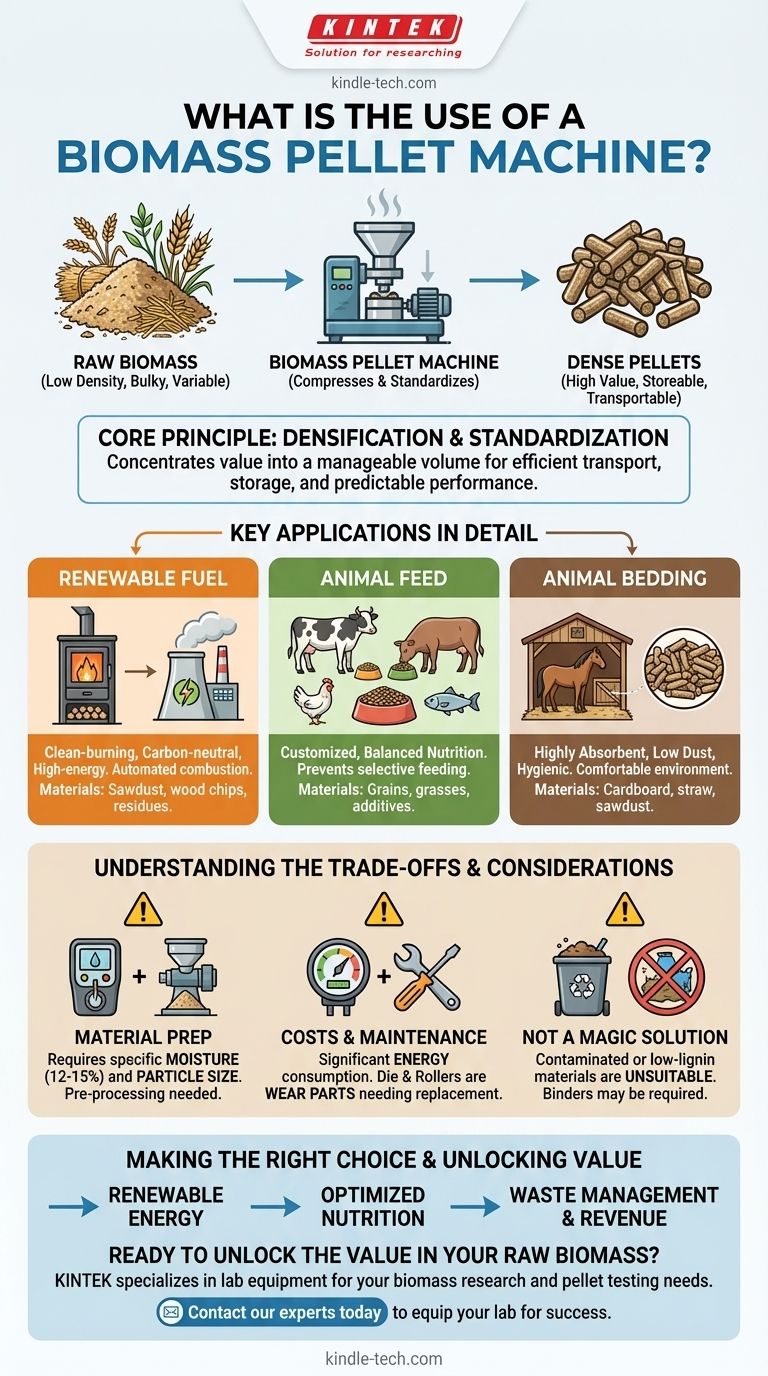

The Core Principle: Densification and Standardization

To understand the value of a pellet machine, you must first grasp the two key transformations it performs on raw biomass.

Why Density Matters

Raw biomass, such as sawdust, straw, or crop stalks, is bulky and has a very low density. This makes it expensive to transport and difficult to store efficiently.

A pellet machine compresses this material, increasing its bulk density significantly. This process concentrates its value—whether for energy or nutrition—into a much smaller, more manageable volume.

The Value of Uniformity

Raw materials are inconsistent in size, shape, and moisture content. This variability makes them incompatible with automated systems, like pellet stoves or automated livestock feeders.

Pelletizing creates a standardized product with a consistent size, shape, and moisture level. This uniformity is critical for predictable performance, whether it's for controlled combustion in a furnace or consistent digestion in an animal.

Key Applications in Detail

The uniform, dense nature of pellets makes them highly versatile for several commercial and personal applications.

Creating Renewable Fuel Pellets

This is one of the most common uses. A pellet machine can convert forestry waste (sawdust, wood chips) and agricultural residues into high-energy fuel pellets.

These pellets serve as a clean-burning, carbon-neutral alternative to fossil fuels for heating homes, commercial buildings, and industrial boilers. Their uniform nature allows for automated and highly efficient combustion.

Producing Animal Feed

The machine allows for the creation of customized feed formulations. Different raw ingredients—like grains, grasses, and nutritional additives—can be mixed and pelletized together.

This process ensures that each pellet contains a complete and balanced nutritional profile. It prevents selective feeding by animals and simplifies the logistics of feeding livestock, poultry, and aquaculture.

Manufacturing Animal Bedding

Materials like cardboard, straw, or sawdust can be pelletized to create superior animal bedding.

These pellets are highly absorbent, low in dust, and easy to store and spread. When they become saturated, they break down into a soft, dry material, creating a comfortable and hygienic environment for animals like horses.

Understanding the Trade-offs and Considerations

While powerful, a pellet machine is not a "plug-and-play" solution. Success depends on understanding its operational requirements.

Material Preparation is Crucial

You cannot feed any raw material directly into the machine. The biomass must have a specific moisture content, typically between 12-15%, to pelletize correctly.

Additionally, the material must be ground to a uniform, small particle size. This often requires pre-processing with equipment like a hammer mill or chipper.

Energy and Maintenance Costs

Pellet machines consume a significant amount of electrical energy to generate the necessary pressure and heat. This operational cost must be factored into your economic calculations.

The core components—the die and rollers—are wear parts that experience extreme forces. They require regular inspection, maintenance, and eventual replacement, which is a primary ongoing expense.

Not a "Magic" Waste Solution

While versatile, not all biomass is suitable for pelleting. Materials with low lignin content (a natural binder in wood) may require the addition of a binding agent.

Furthermore, materials contaminated with dirt, plastics, or chemicals are unsuitable, as they can damage the machine and result in a low-quality or unsafe final product.

Making the Right Choice for Your Goal

To determine if this technology fits your needs, consider your primary objective.

- If your primary focus is generating renewable fuel: A pellet machine is ideal for converting forestry or agricultural waste into a high-density energy source for heating applications.

- If your primary focus is optimizing animal nutrition: It allows you to create customized, consistent feed pellets from your own raw ingredients, giving you full control over your animals' diet.

- If your primary focus is managing waste streams: It can turn low-value byproducts like sawdust or cardboard into a sellable commodity like bedding or fuel, creating a new revenue stream.

Ultimately, a biomass pellet machine empowers you to unlock the hidden logistical and economic value in raw organic materials.

Summary Table:

| Application | Key Benefit | Common Materials |

|---|---|---|

| Renewable Fuel | Clean-burning, high-energy alternative to fossil fuels | Sawdust, wood chips, agricultural residues |

| Animal Feed | Customized, balanced nutrition; prevents selective feeding | Grains, grasses, nutritional additives |

| Animal Bedding | Highly absorbent, low-dust, and easy to store/spread | Cardboard, straw, sawdust |

Ready to unlock the value in your raw biomass?

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and research facilities. Whether you are developing new biomass formulations or testing pellet quality, our equipment can support your innovation.

Contact our experts today to discuss how we can help equip your lab for success.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Touchscreen Automatic Vacuum Heat Press

People Also Ask

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- What advantages does a hot press offer over cold pressing? Enhance Sulfide Solid-State Electrolyte Performance

- What is the function of a laboratory hydraulic hot press in the assembly of solid-state photoelectrochemical cells?

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production