In essence, hot isostatic pressing (HIP) is a material enhancement process. It uses a combination of inert gas, high pressure, and elevated temperature to fundamentally improve the properties of metals, ceramics, and other advanced materials. The primary uses of this process are to eliminate internal defects in castings, consolidate powders into a solid mass, and create inseparable bonds between dissimilar materials.

The fundamental value of hot isostatic pressing is its ability to transform imperfect or powdered materials into fully dense, high-integrity components. It is not just a manufacturing step, but a critical tool for achieving the material properties required for the most demanding engineering applications.

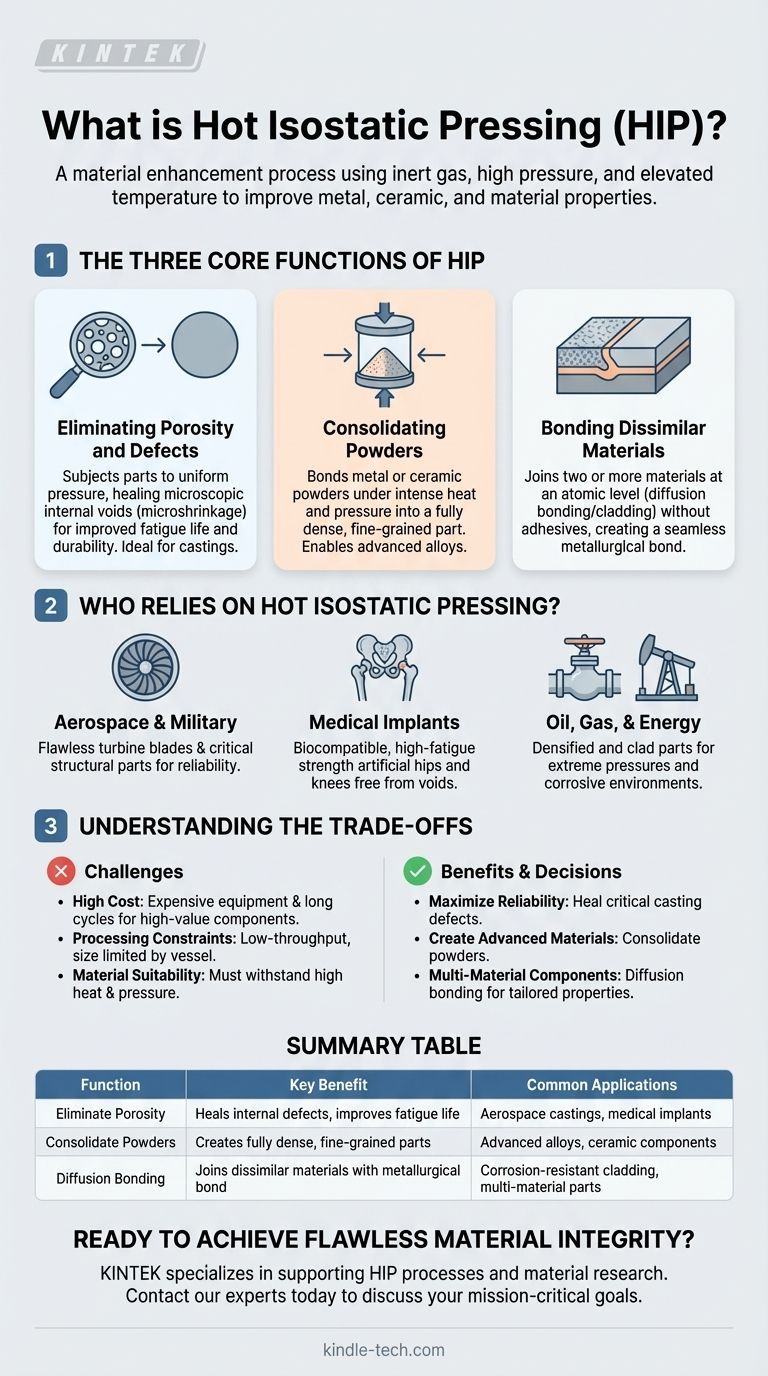

The Three Core Functions of HIP

Hot isostatic pressing is not one single application but rather a versatile thermal treatment process with three distinct primary functions. Each function solves a critical material engineering challenge.

Eliminating Porosity and Defects

Many manufacturing methods, especially casting, can leave behind microscopic internal voids or pores within a part. These defects, known as microshrinkage, act as stress concentration points and can lead to premature failure.

HIP subjects these parts to uniform pressure from all directions. This pressure physically collapses and welds shut the internal voids, effectively healing the material from the inside out.

The result is a fully dense component with vastly improved mechanical properties, particularly fatigue life and durability.

Consolidating Powders (Powder Metallurgy)

HIP is also used to create solid parts from metal or ceramic powders. The powders are first sealed in a metallic container, or "can," that is shaped like the final component.

Under intense heat and pressure, the individual powder particles bond and fuse together, forming a fully dense part with a fine-grained, uniform microstructure.

This method allows for the creation of advanced alloys and composite materials that cannot be produced through conventional melting and casting.

Bonding Dissimilar Materials (Diffusion Bonding)

This process, also known as cladding, uses HIP to join two or more different materials at an atomic level without any adhesives or filler material.

By placing different materials in intimate contact within the HIP vessel, the high temperature and pressure promote atomic diffusion across the boundary.

This creates a seamless, metallurgical bond that is as strong as the parent materials, perfect for applying wear-resistant or corrosion-resistant layers to a component.

Who Relies on Hot Isostatic Pressing?

The demanding nature of the HIP process means it is employed in industries where component failure is not an option. Its ability to create parts with superior integrity is critical for high-stakes applications.

Aerospace and Military

In aerospace, components like turbine blades and critical structural parts must be flawless. HIP is used to eliminate any internal defects from castings, ensuring maximum reliability and resistance to fatigue under extreme operating conditions.

Medical Implants

The human body is a demanding environment. Medical implants, such as artificial hips and knees, must be biocompatible and possess exceptional fatigue strength to last for decades. HIP ensures these cast or powder-metal parts are free from voids that could lead to failure.

Oil, Gas, and Energy

Components used in the energy sector, such as valves, pumps, and connectors, are often exposed to extreme pressures and corrosive environments. HIP is used to densify these parts and to clad them with corrosion-resistant alloys, significantly extending their service life and safety.

Understanding the Trade-offs

While powerful, hot isostatic pressing is a specialized process with specific considerations that make it unsuitable for general-purpose manufacturing.

The Cost Factor

HIP equipment and the process itself are expensive. The combination of high pressure, high temperature, and long cycle times contributes to a significant cost per part.

For this reason, HIP is almost exclusively reserved for high-value or safety-critical components where the performance improvement justifies the expense.

Processing Constraints

The HIP cycle—including heating, holding at temperature and pressure, and cooling—can take many hours. This makes it a relatively low-throughput process compared to other manufacturing methods.

Furthermore, the size of the components that can be treated is limited by the internal dimensions of the HIP vessel.

Material Suitability

The process is ideal for a wide range of materials, including metals, ceramics, composites, and some plastics. However, the material must be able to withstand the high temperatures and pressures without degrading.

Making the Right Choice for Your Goal

Deciding whether to use hot isostatic pressing depends entirely on the required performance and reliability of your final component.

- If your primary focus is maximizing reliability and fatigue life: Use HIP to heal defects in critical castings for industries like aerospace or medical.

- If your primary focus is creating advanced materials with superior properties: Use HIP to consolidate powders into high-performance parts that are impossible to make with traditional casting or forging.

- If your primary focus is creating multi-material components: Use HIP for diffusion bonding to create inseparable, clad parts with tailored surface properties, such as corrosion resistance.

Ultimately, hot isostatic pressing is the definitive solution when a material's internal integrity is paramount to its function and safety.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Eliminate Porosity | Heals internal defects, improves fatigue life | Aerospace castings, medical implants |

| Consolidate Powders | Creates fully dense, fine-grained parts | Advanced alloys, ceramic components |

| Diffusion Bonding | Joins dissimilar materials with a metallurgical bond | Corrosion-resistant cladding, multi-material parts |

Ready to achieve flawless material integrity for your critical components?

Hot isostatic pressing is the definitive solution for maximizing the reliability, durability, and performance of high-stakes parts. KINTEK specializes in providing the advanced lab equipment and consumables needed to support HIP processes and material research.

Whether you are developing components for aerospace, medical implants, or energy applications, our expertise can help you ensure material properties where failure is not an option.

Contact our experts today to discuss how we can support your mission-critical material enhancement goals.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance