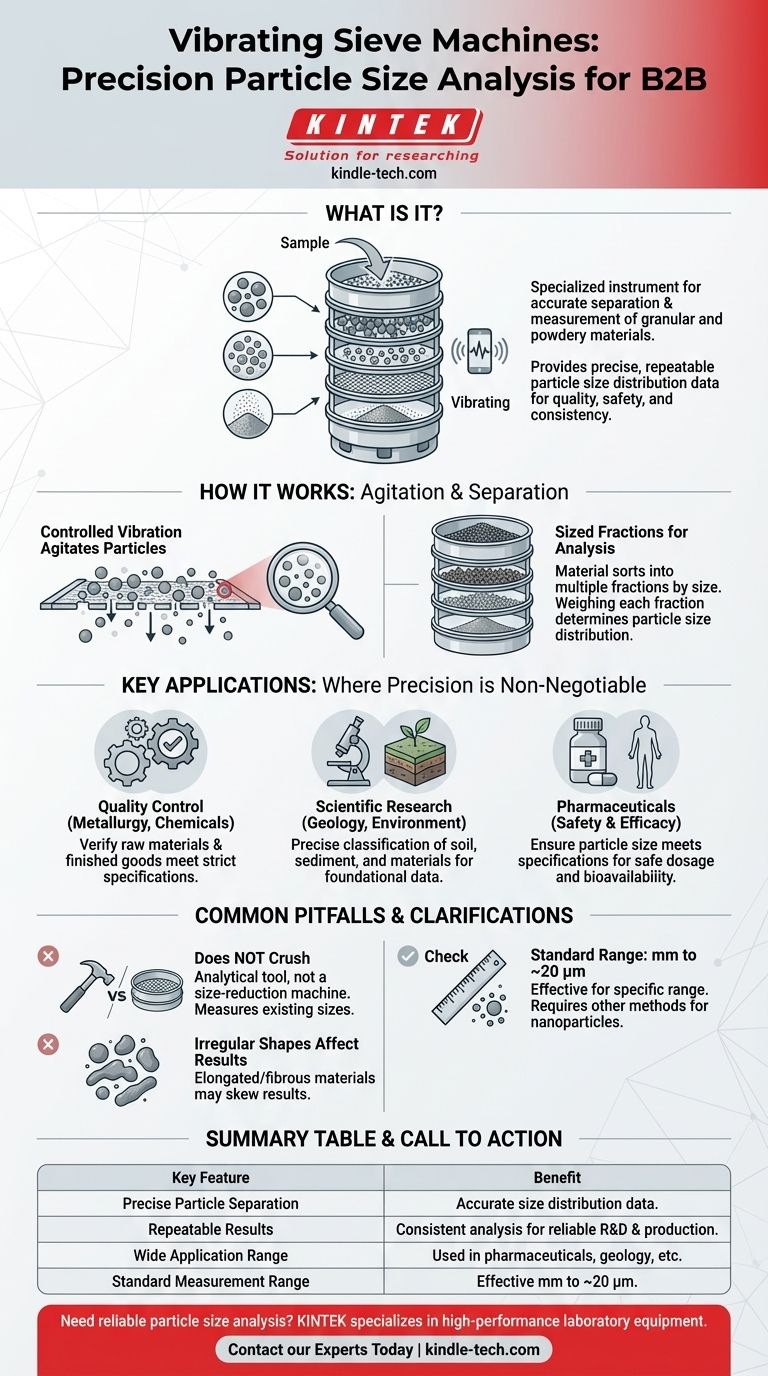

At its core, a vibrating sieve machine, often called a sieve shaker, is a specialized instrument used for a single, critical purpose: to accurately separate and measure the particle size distribution of granular and powdery materials. It is an essential tool for quality control and laboratory analysis across a vast range of scientific and industrial fields.

The fundamental value of a vibrating sieve is not just to sort materials, but to provide precise, repeatable data that ensures product quality, safety, and consistency. It transforms a mixed sample into a clear profile of its particle size structure.

How a Vibrating Sieve Provides Clarity

A vibrating sieve operates on a straightforward yet highly effective principle of mechanical separation. Understanding its mechanism reveals why it has become a standard for material analysis.

The Principle of Agitation and Separation

A sample of granular or powdered material is placed into the top of a stack of sieves. Each sieve in the stack has a screen with a specific mesh size, with the largest openings at the top and the finest at the bottom.

The machine then generates a controlled vibration. This agitation causes the particles to move across the sieve screens, passing through openings larger than themselves until they are retained by a screen with openings too small to pass.

From a Mixed Sample to Sized Fractions

This process effectively sorts the initial sample into multiple fractions, each containing particles within a specific size range. By weighing the material retained on each sieve, an operator can accurately determine the particle size distribution of the original sample.

This data is crucial for understanding the physical characteristics of a material, from soil and sand in geology to fine powders in the pharmaceutical industry.

Where Precise Particle Sizing is Non-Negotiable

The applications for vibrating sieves are extensive, but they are most critical in fields where particle size directly impacts performance, safety, or quality.

Quality Control in Industry

In industries like metallurgy, chemicals, and abrasives, the size of the constituent particles determines the properties of the final product. A vibrating sieve is used to verify that raw materials and finished goods meet strict size specifications, preventing production failures and ensuring product consistency.

Foundational Tool for Scientific Research

For geologists analyzing soil or sediment composition, a sieve shaker is an indispensable tool. It allows for the precise classification of materials, which is fundamental to understanding geological formations and environmental conditions.

Ensuring Safety in Pharmaceuticals

In medicine and pharmacopoeia, the particle size of an active ingredient can dramatically affect its dissolution rate and bioavailability in the body. Vibrating sieves ensure that drug powders meet the exact specifications required for safe and effective dosages.

Common Pitfalls and Clarifications

While powerful, it's important to understand the specific role and limitations of this equipment to use it effectively.

It Separates, It Does Not Crush

A vibrating sieve is an analytical instrument, not a size-reduction machine. It is often confused with a vibrating mill, which uses grinding balls and high-impact vibration to crush brittle materials into a fine powder. A sieve measures existing sizes; a mill creates smaller sizes.

The Impact of Particle Shape

The accuracy of sieve analysis assumes relatively uniform or spherical particles. Highly irregular, elongated, or fibrous materials may pass through mesh openings differently than expected, which can skew results.

Measurement Range Limitations

Standard laboratory sieve shakers are highly effective for measuring particles in a range from several millimeters down to approximately 20 micrometers (μm). For particles smaller than this (nanoparticles), other methods like laser diffraction are required.

How to Apply This to Your Project

Choosing and using a vibrating sieve correctly depends entirely on your end goal.

- If your primary focus is quality control: Use it to establish a consistent, repeatable baseline for verifying that incoming raw materials and outgoing products meet required specifications.

- If your primary focus is research and development: Employ it to accurately characterize new materials or analyze the physical composition of samples to gather foundational data.

- If your primary focus is process troubleshooting: Use it to analyze samples from different stages of production to pinpoint where inconsistencies in particle size may be occurring.

Ultimately, the vibrating sieve is a cornerstone instrument for anyone who needs to guarantee the physical integrity and consistency of a granular material.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Precise Particle Separation | Ensures accurate size distribution data for quality control. |

| Repeatable Results | Provides consistent analysis for reliable R&D and production. |

| Wide Application Range | Used in pharmaceuticals, geology, metallurgy, and chemicals. |

| Standard Measurement Range | Effective for particles from millimeters down to ~20 micrometers. |

Need reliable particle size analysis for your quality control or research? KINTEK specializes in high-performance laboratory equipment, including vibrating sieve machines, designed to deliver the accuracy and consistency your lab demands. Contact our experts today to find the perfect solution for your material analysis needs and ensure your product quality and safety.

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- How is a vibrating sieve shaker used to classify atomized Al-Fe-Ni powders? Expert Guide to Particle Size Control

- What role does a laboratory vibrating sieve shaker play in the LiFePO4 powder processing workflow? Ensure Batch Quality

- What is the frequency of a sieve shaker? The Key to Accurate Particle Size Analysis

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- What are the principles of a sieve shaker? Achieve Accurate Particle Size Analysis