At its core, a vibratory sieve shaker is a laboratory instrument designed for one primary purpose: to accurately and efficiently separate granular or powdered materials by particle size. It automates the process of passing a sample through a stack of sieves with progressively smaller mesh openings, providing a clear picture of the material's particle size distribution.

The true value of a sieve shaker lies in its ability to replace inconsistent manual sieving with a standardized, repeatable, and rapid method for particle analysis. It provides the data integrity required for quality control, research, and production across a vast range of industries.

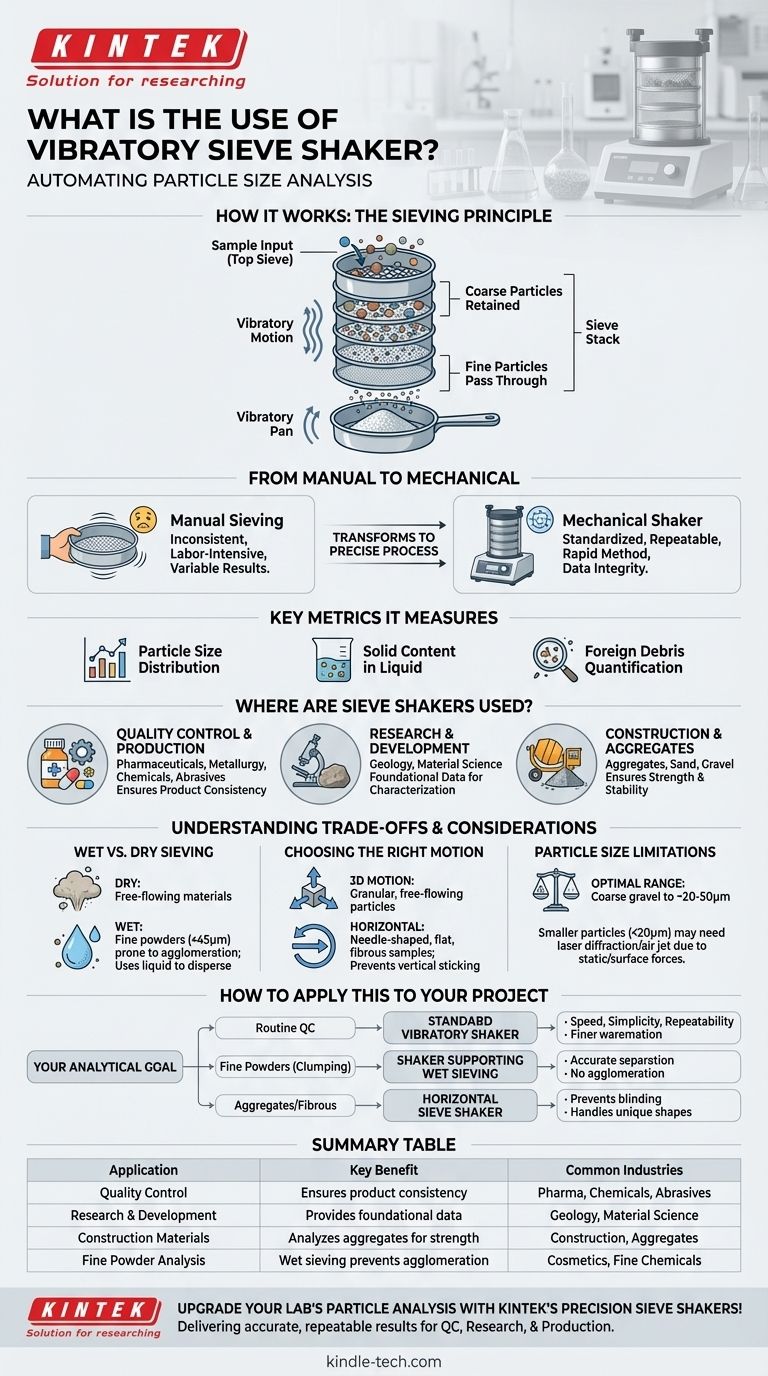

The Core Function: Automating Particle Size Analysis

A sieve shaker transforms the labor-intensive task of hand-sieving into a precise and automated scientific process. This automation is the key to its widespread adoption in labs and quality inspection rooms.

How It Works: The Sieving Principle

A sieve shaker uses a controlled vibratory motion to agitate a stack of test sieves. The sample material is placed in the top sieve, which has the largest mesh openings.

The vibration causes particles to move across the sieve mesh. Particles smaller than the mesh openings fall through to the sieve below, while larger particles are retained. This process continues down the entire sieve stack, effectively sorting the material into different size fractions.

From Manual to Mechanical

Without a shaker, technicians must perform this process by hand. Manual sieving is notoriously difficult to standardize, leading to results that vary significantly between operators and even between tests by the same operator.

A mechanical shaker eliminates this variability by applying a consistent energy and motion—often a three-dimensional throwing motion—to the sieve stack. This ensures that results are both accurate and highly repeatable, which is critical for scientific validity and quality assurance.

Key Metrics It Measures

The primary output of a sieve analysis is the particle size distribution of a sample. Beyond this, it is also used to determine the solid content in a liquid or to quantify the amount of foreign debris in a material.

Where are Sieve Shakers Used?

The ability to deliver precise and repeatable particle analysis makes sieve shakers indispensable in numerous fields.

Quality Control and Production

In industries like pharmaceuticals, metallurgy, chemicals, and abrasives, maintaining a consistent particle size is often critical to the final product's performance and safety. Sieve shakers are used to verify that raw materials and finished goods meet strict specifications.

Research and Development

Geologists, material scientists, and other researchers use sieve shakers to characterize new materials or analyze natural samples like soil and sediment. The instrument provides foundational data for a wide range of scientific investigations.

Construction and Aggregates

The construction industry relies on sieve shakers to analyze the particle size of aggregates, sand, and gravel. This is crucial for ensuring the strength and stability of materials like concrete and asphalt.

Understanding the Trade-offs and Key Considerations

While highly effective, choosing and using a sieve shaker requires understanding its operational nuances and limitations.

Wet vs. Dry Sieving

Dry sieving is the standard method for most free-flowing materials. However, for very fine powders (typically below 45μm) that tend to agglomerate or stick together due to static electricity, wet sieving is often necessary.

In wet sieving, a liquid (usually water) is used to disperse the particles and carry them through the sieve meshes, preventing blockages and ensuring an accurate separation of fine material.

Choosing the Right Motion

Most vibratory shakers impart a 3D motion that is effective for granular, free-flowing particles. However, a horizontal sieve shaker is preferred for samples that are needle-shaped, flat, long, or fibrous. The horizontal circular motion keeps these particles from getting stuck vertically in the sieve openings.

Particle Size Limitations

Vibratory sieve shakers are excellent for analyzing materials from coarse gravel down to fine powders, typically around 20 to 50 micrometers (μm). For particles smaller than this, other methods like laser diffraction or air jet sieving may be more appropriate as tiny particles can be heavily influenced by static and surface forces.

How to Apply This to Your Project

Your choice of sieving method depends entirely on your material and your analytical goal.

- If your primary focus is routine quality control: The speed, simplicity, and excellent repeatability of a standard vibratory sieve shaker are its most significant advantages.

- If your primary focus is analyzing fine powders that clump: Consider a shaker that supports wet sieving to ensure accurate separation without agglomeration.

- If your primary focus is analyzing aggregates or fibrous materials: A horizontal sieve shaker is likely the better choice to prevent sieve blinding and handle larger, uniquely shaped samples effectively.

Ultimately, a vibratory sieve shaker provides the reliable data needed to control quality, advance research, and ensure materials perform exactly as intended.

Summary Table:

| Application | Key Benefit | Common Industries |

|---|---|---|

| Quality Control | Ensures product consistency and meets specifications | Pharmaceuticals, Chemicals, Abrasives |

| Research & Development | Provides foundational data for material characterization | Geology, Material Science |

| Construction Materials | Analyzes aggregates for strength and stability | Construction, Aggregates |

| Fine Powder Analysis | Wet sieving prevents agglomeration for accurate separation | Cosmetics, Fine Chemicals |

Upgrade your lab's particle analysis with KINTEK's precision sieve shakers!

Are you struggling with inconsistent manual sieving or need reliable data for quality control? KINTEK specializes in lab equipment and consumables, serving laboratory needs with vibratory sieve shakers that deliver accurate, repeatable particle size distribution results. Whether you work in pharmaceuticals, construction, or research, our shakers automate your process, save time, and ensure data integrity.

Contact us today to find the perfect sieve shaker for your materials and boost your lab's efficiency!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the function of the sieve shaker machine? Achieve Accurate Particle Size Analysis

- What is the significance of using a laboratory constant-temperature shaker in corrosion inhibitor biodegradation study?

- What is the principle of sieving method? Achieve Accurate Particle Size Separation

- Which equipment is operated for sieves when perform sieving tests? Achieve Accurate Particle Size Analysis

- Why use reciprocating shakers for AMD & hospital wastewater co-treatment? Optimize nZVI Reaction Kinetics

- How does a sieve shaker work? A Guide to Automated Particle Size Analysis

- What role does a laboratory orbital shaker play in AHP pretreatment? Achieve Uniform Delignification for Cassava Stems

- Why are crushing and sieving systems indispensable prior to the recovery of platinum? Maximize Your Extraction Yield