At its core, a vibrating sieve is a laboratory instrument used for particle size analysis. More accurately known as a sieve shaker, it uses controlled vibration to separate granular materials and powders through a stack of sieves with progressively smaller mesh openings. This process allows you to accurately measure the particle size distribution within a sample, rather than just separating it.

A sieve shaker does not simply sort particles; it is a precision measurement tool. Its primary function is to provide quantitative data on the size range and proportions of particles in a sample, which is fundamental for quality control and research in numerous scientific and industrial fields.

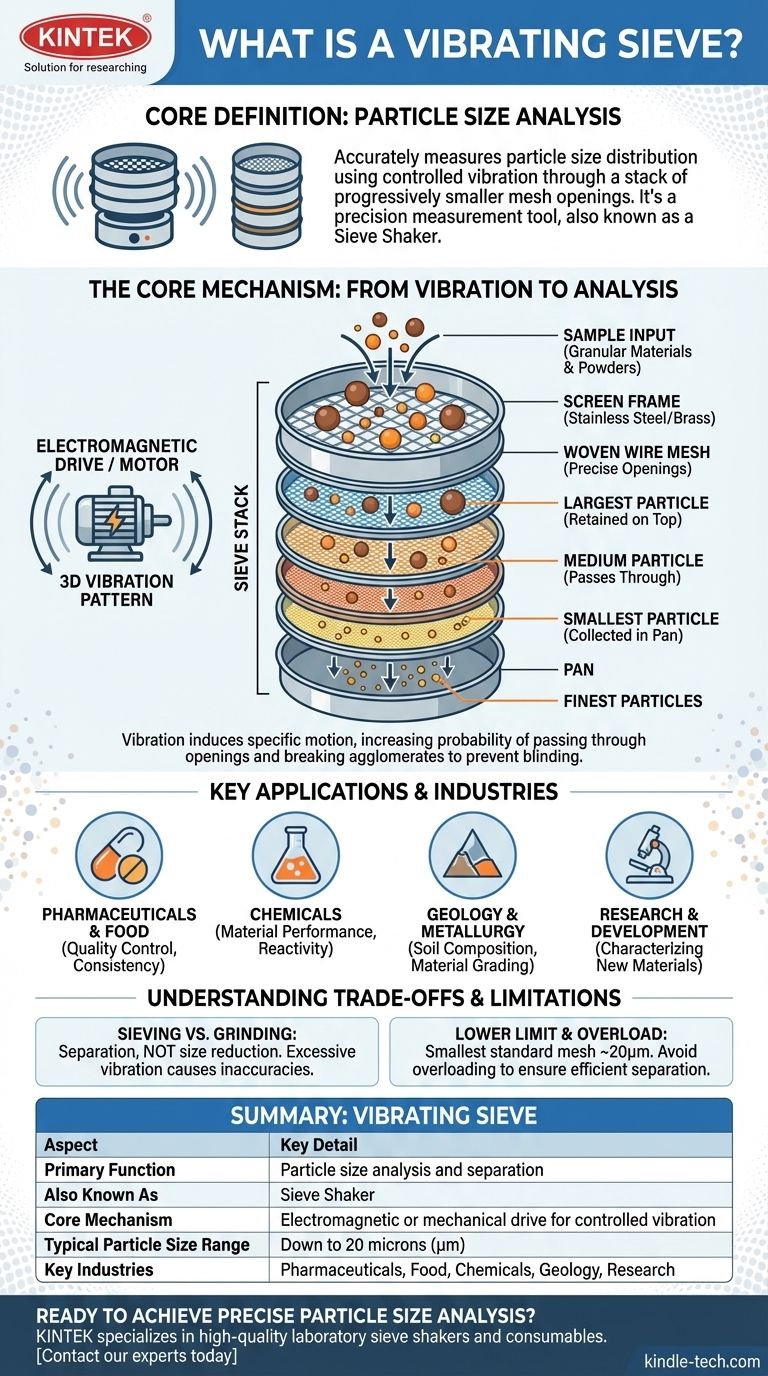

The Core Function: From Vibration to Analysis

A sieve shaker's operation is based on a simple, effective principle. It converts electrical energy into mechanical vibration to agitate a column of stacked test sieves.

The Sieve Stack: A Cascade of Precision

The heart of the system is the sieve stack. A sample is placed in the top sieve, which has the largest mesh openings.

Each sieve consists of a screen frame, typically made of stainless steel or brass, which holds a precisely manufactured woven wire mesh.

As the machine vibrates, particles small enough to pass through the top mesh fall onto the sieve below it, which has a slightly smaller opening size. This process continues down the stack, creating a particle size gradient.

A solid pan at the bottom of the stack collects the finest particles that have passed through every sieve.

The Drive Mechanism: The Engine of Separation

The vibration itself is generated by an electromagnetic drive or a mechanical motor with an offset weight (an exciter). This drive imparts energy into the entire sieve stack.

The goal is not just to shake the particles, but to induce a specific motion that makes them jump and reorient, increasing the probability that they will find and pass through a mesh opening.

Vibration Pattern: More Than Just Shaking

Basic shakers may use a simple 2D tapping or orbital motion. However, more advanced systems use a 3D vibration pattern.

This three-dimensional motion throws particles upward and across the sieve surface simultaneously. This action is critical for breaking up agglomerated particles and preventing blinding—a condition where particles get stuck in the mesh openings, blocking flow and skewing results.

Key Applications and Industries

The ability to determine particle size distribution is critical across many sectors for ensuring material quality, consistency, and performance.

Quality Control and Production

In industries like pharmaceuticals, food production, and chemicals, sieve shakers are used to verify that raw materials and finished products meet strict particle size specifications. This ensures factors like dissolution rates, texture, and chemical reactivity are consistent from batch to batch.

Research and Geology

In scientific research, metallurgy, and geology, a sieve shaker is a fundamental tool for characterizing new materials, analyzing soil composition, or grading abrasives. It provides the foundational data needed to understand a material's physical properties.

Understanding the Trade-offs and Limitations

While powerful, a sieve shaker is not a universal solution for all particle analysis. Understanding its limitations is key to generating accurate data.

Sieving vs. Grinding: A Critical Distinction

A sieve shaker is a tool for separation and analysis, not size reduction. The vibration should be just energetic enough to move particles, not so violent that it breaks them down. If particles are fracturing during analysis, the resulting data will be inaccurate, showing a finer distribution than the original sample. This is why it is distinct from a vibrating mill, which is designed to grind materials.

The Lower Particle Size Limit

Woven wire mesh has a practical manufacturing limit. The smallest standard sieve opening is around 20 microns (μm). For analyzing sub-micron particles (nanoparticles), other methods like laser diffraction or dynamic light scattering are required.

The Risk of Sample Overload

Placing too much sample material on the top sieve is a common mistake. An overloaded sieve prevents particles from moving freely, leading to inefficient separation and inaccurate results. Each sieve has an optimal particle load for best performance.

Making the Right Choice for Your Goal

The primary value of a sieve shaker is its ability to provide reliable, repeatable data on particle size distribution.

- If your primary focus is routine quality control: Prioritize using a set of certified, matched sieves and a standardized procedure to ensure your results are consistent and comparable over time.

- If your primary focus is research and development: Use a sieve shaker to build a complete profile of your material's particle size distribution, as this will directly influence its physical and chemical behavior.

- If your primary focus is sorting bulk materials like aggregates or soil: The sieve shaker is the industry standard for classifying materials according to established size grades.

Ultimately, the vibrating sieve shaker is an essential instrument that provides the foundational data for understanding, controlling, and innovating with particulate materials.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Particle size analysis and separation |

| Also Known As | Sieve Shaker |

| Core Mechanism | Electromagnetic or mechanical drive for controlled vibration |

| Typical Particle Size Range | Down to 20 microns (μm) |

| Key Industries | Pharmaceuticals, Food, Chemicals, Geology, Research |

Ready to achieve precise particle size analysis in your lab?

KINTEK specializes in high-quality laboratory sieve shakers and consumables designed for accurate and repeatable results. Whether your focus is rigorous quality control or advanced R&D, our equipment helps you characterize materials with confidence.

Contact our experts today to find the perfect sieving solution for your specific needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

- Laboratory Oscillating Orbital Shaker

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis