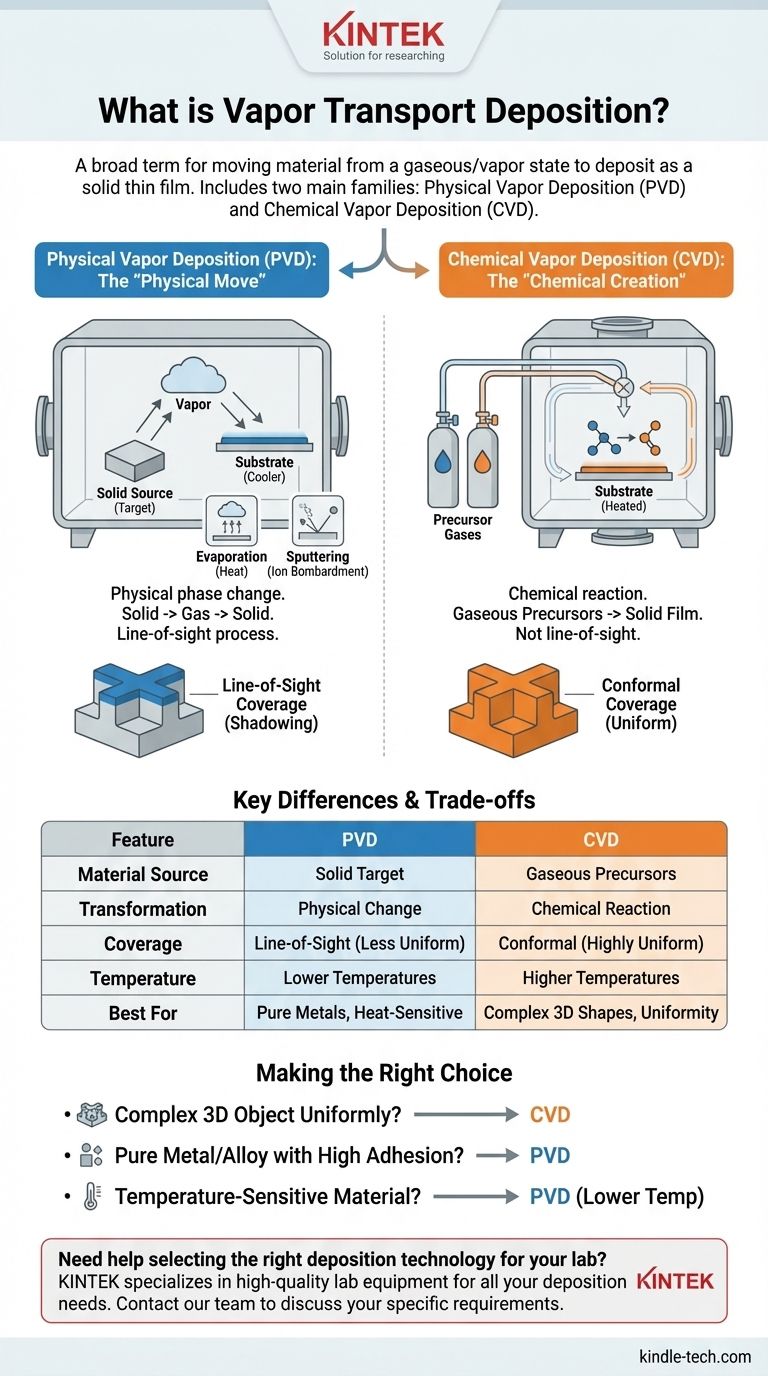

In short, vapor transport deposition is not a single process but a broad term describing methods that move a material in a gaseous or vapor state to deposit it as a solid thin film onto a surface. This category primarily encompasses two distinct families of technology: Physical Vapor Deposition (PVD), where the material is physically moved, and Chemical Vapor Deposition (CVD), where a new material is created at the surface through a chemical reaction.

The critical distinction is how the material travels. In PVD, you are essentially spray-painting with atoms that are physically vaporized from a solid source. In CVD, you are introducing precursor gases that react and "bake" a new solid layer directly onto the target surface.

Physical Vapor Deposition (PVD): The "Physical Move"

Physical Vapor Deposition, sometimes called Physical Vapor Transport (PVT), is a process that involves a purely physical state change. The material being deposited starts as a solid, becomes a gas, and finishes as a solid again, without changing its chemical identity.

The Mechanism: From Solid to Vapor

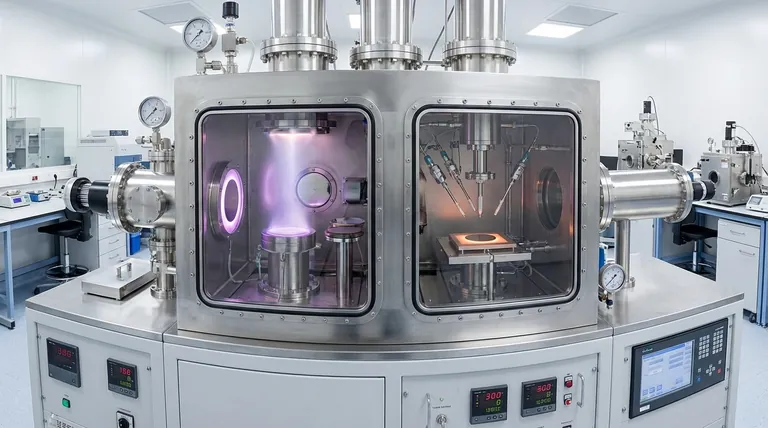

The process takes place in a vacuum chamber and begins by turning a solid source material (known as the "target") into a vapor.

This is typically achieved through one of two methods: evaporation, where the material is heated until it vaporizes, or spraying (sputtering), where the target is bombarded with high-energy ions, knocking atoms loose.

Condensation on the Substrate

Once in a vapor state, these atoms or molecules travel through the vacuum and condense onto the cooler substrate (the part being coated).

This direct, line-of-sight transfer forms a thin, solid film. This process is excellent for depositing materials with very high melting points.

Chemical Vapor Deposition (CVD): The "Chemical Creation"

Chemical Vapor Deposition relies on a chemical reaction to form the coating. Instead of starting with the final material in solid form, you begin with one or more volatile precursor gases.

The Mechanism: Precursor Gas to Solid Film

The substrate is placed inside a reaction chamber, and precursor gases—which contain the atoms needed for the final film—are introduced.

The chamber is heated to a specific reaction temperature, providing the energy needed to trigger a chemical change.

The Reaction at the Surface

The precursor gases react or decompose on the hot substrate surface, leaving behind the desired solid material as a coating.

Other gaseous byproducts from the reaction are simply transported away. This process allows the coating to "grow" on the surface, molecule by molecule.

Understanding the Key Differences and Trade-offs

Choosing between PVD and CVD requires understanding their fundamental differences, as each has distinct advantages.

The Material Source

PVD uses a solid source of the exact material you want to deposit.

CVD uses volatile precursor gases that chemically combine or break down to form the desired material on the surface.

The Transformation Process

The core of PVD is a physical phase change: solid to gas and back to solid.

The core of CVD is a chemical reaction that creates an entirely new solid product from gaseous reactants.

Coverage and Conformality

Because PVD is a line-of-sight process, it can struggle to coat complex, three-dimensional shapes uniformly. Areas not in the direct path of the vapor source receive little to no coating.

CVD is not a line-of-sight process. The precursor gases can flow around and react on all exposed surfaces, resulting in an exceptionally uniform (conformal) coating, even on intricate parts.

Operating Conditions

CVD often requires high substrate temperatures to drive the necessary chemical reactions.

PVD processes can frequently be performed at lower temperatures, making them suitable for coating materials that cannot withstand high heat.

Making the Right Choice for Your Application

Your final goal dictates which method is more appropriate.

- If your primary focus is coating a complex, 3D object uniformly: CVD is often the superior choice because the chemical reaction can occur on all surfaces simultaneously.

- If your primary focus is depositing a pure metal or alloy with high adhesion: PVD is a direct and powerful method well-suited for this, especially for high-performance metallic coatings.

- If your primary focus is coating a temperature-sensitive material: A lower-temperature PVD process is likely the more viable option to avoid damaging the substrate.

Ultimately, understanding whether your material needs to be physically moved or chemically created is the key to selecting the right deposition technology for your project.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Material Source | Solid target material | Gaseous precursor chemicals |

| Transformation | Physical phase change | Chemical reaction |

| Coverage | Line-of-sight (less uniform) | Conformal (highly uniform) |

| Temperature | Lower temperatures | Higher temperatures |

| Best For | Pure metals, heat-sensitive substrates | Complex 3D shapes, uniform coatings |

Need help selecting the right deposition technology for your lab? The choice between PVD and CVD is critical for your thin film application's success. At KINTEK, we specialize in providing high-quality lab equipment and consumables for all your deposition needs. Our experts can help you choose the perfect solution for coating complex shapes, temperature-sensitive materials, or achieving high-purity metallic layers. Contact our team today to discuss your specific requirements and discover how KINTEK can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition