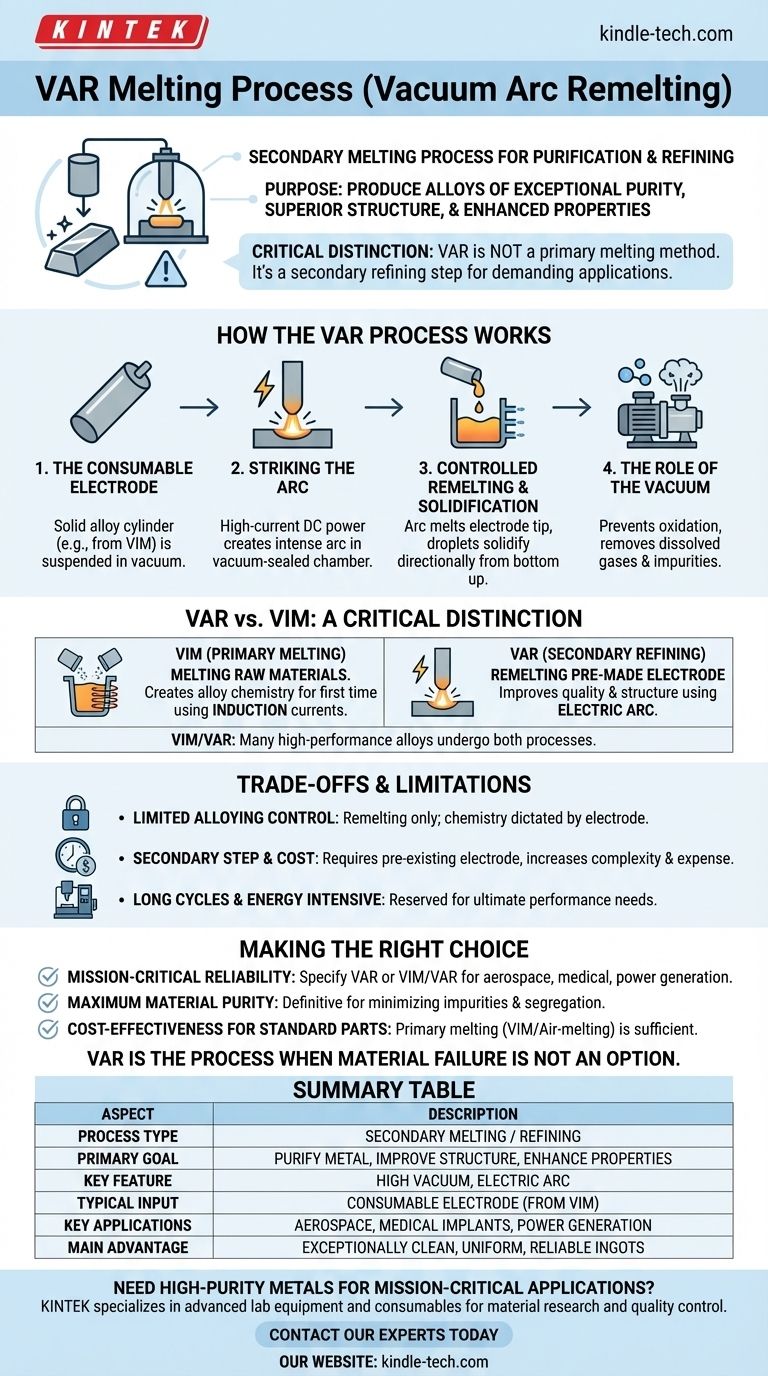

In essence, Vacuum Arc Remelting (VAR) is a secondary melting process used to purify and refine metals and alloys that have already been melted once. It operates under a high vacuum, using a powerful electric arc to progressively melt a solid cylindrical electrode, which then re-solidifies in a water-cooled copper mold to form a new, highly uniform and clean ingot.

The critical distinction to understand is that VAR is not a primary melting method for raw materials. It is a secondary refining step designed to produce alloys with exceptional purity, a superior internal structure, and enhanced mechanical properties required for the most demanding applications.

How the VAR Process Works

The VAR process is a highly controlled, methodical procedure designed to systematically remove impurities and perfect the alloy's structure. It is a batch process, refining one electrode at a time.

The Consumable Electrode

The process begins with a solid cylinder of the alloy, known as a consumable electrode. This electrode is typically produced first by a primary melting process like Vacuum Induction Melting (VIM).

Striking the Arc

The electrode is suspended inside a vacuum-sealed chamber, positioned above a water-cooled copper crucible or mold. A high-current DC power source is applied, creating an intense electric arc between the bottom tip of the electrode and a small amount of starter material at the base of the mold.

Controlled Remelting and Solidification

The immense heat from the arc (often exceeding the metal's melting point) melts the tip of the electrode. This molten metal falls in droplets into the crucible below. Because the crucible is actively water-cooled, the molten metal solidifies almost immediately upon contact in a highly controlled, directional manner from the bottom up.

The Role of the Vacuum

Maintaining a high vacuum is fundamental to the process. The vacuum environment prevents the hot metal from reacting with atmospheric gases like oxygen and nitrogen. It also helps pull dissolved gases (like hydrogen) and low-boiling-point impurities out of the molten droplets as they fall, effectively cleaning the metal.

VAR vs. VIM: A Critical Distinction

While both are vacuum processes, VAR and VIM serve different purposes and should not be confused. Many high-performance alloys undergo both processes, often referred to as "VIM/VAR."

VIM is for Primary Melting

Vacuum Induction Melting (VIM) is a primary melting process. It uses electromagnetic induction to melt a "charge" of raw metals and alloying elements together inside a refractory-lined crucible to create an alloy with a specific chemistry for the first time.

VAR is for Secondary Refining

VAR takes the solid ingot (electrode) produced by VIM and remelts it. Its goal is not to create the alloy's chemistry, but to dramatically improve its quality by removing impurities, eliminating segregation, and creating a highly uniform grain structure.

Heat Source and Purpose

The key difference lies in the heat source and intent. VIM uses induction currents to melt and mix ingredients. VAR uses an electric arc to remelt and purify a pre-made electrode.

Understanding the Trade-offs and Limitations

While VAR produces exceptional quality, it is a specialized process with inherent limitations that make it suitable only for specific applications.

Limited Alloying Control

VAR is purely a remelting process. The chemical composition of the final ingot is almost entirely dictated by the composition of the starting electrode. Fine-tuning the alloy's chemistry is not possible during the VAR cycle.

It Is a Secondary Step

VAR cannot be used to melt raw materials from scratch. It always requires a pre-existing, solid electrode, which adds a significant step, cost, and complexity to the overall manufacturing chain.

Cost and Scale

The equipment is expensive, the cycle times are long, and the process is energy-intensive. This makes VAR a costly manufacturing route reserved for materials where ultimate performance and reliability justify the expense.

Making the Right Choice for Your Goal

Specifying a VAR-processed material is a decision driven entirely by the performance requirements of the final component.

- If your primary focus is mission-critical reliability (aerospace, medical, power generation): You must specify a VAR or double-melt (VIM/VAR) material to achieve the necessary fatigue life and fracture toughness.

- If your primary focus is maximum material purity and structural integrity: VAR is the definitive process for minimizing dissolved gases, non-metallic inclusions, and segregation in superalloys and specialty steels.

- If your primary focus is cost-effectiveness for standard industrial parts: A primary melting process like VIM or even conventional air-melting will likely provide sufficient performance at a much lower cost.

Ultimately, VAR is the process you rely on when material failure is not an option.

Summary Table:

| Aspect | Description |

|---|---|

| Process Type | Secondary Melting / Refining |

| Primary Goal | Purify metal, improve structure, enhance mechanical properties |

| Key Feature | Melting under high vacuum using an electric arc |

| Typical Input | Consumable electrode (e.g., from VIM process) |

| Key Applications | Aerospace components, medical implants, power generation turbines |

| Main Advantage | Produces exceptionally clean, uniform, and reliable ingots |

Need high-purity metals for mission-critical applications? The VAR process is essential for achieving the reliability and performance required in aerospace, medical, and energy sectors. KINTEK specializes in providing the advanced lab equipment and consumables needed for material research and quality control in these demanding fields. Contact our experts today to discuss how our solutions can support your high-performance material needs.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the temperature of sinter making? Achieve the Perfect Balance for Blast Furnace Efficiency

- What are the different types of high temperature furnaces? A Guide to Box, Tube, Induction & Vacuum Models

- What metals are capable of being heat treated? Unlock High Strength & Durability for Your Components

- How does vacuum brazing work? Achieve Superior, Flux-Free Metal Joining

- What are the units for vacuum pressure? Torr, mbar, and Pascal Explained

- What role does a high-vacuum high-temperature furnace play for AISI 316? Ensure Pure Microstructural Standardization

- Are brazed joints stronger than welded joints? Choosing the Right Joining Method for Your Assembly

- What is the function of a vacuum drying oven in catalyst recovery? Maximize Cycle Life and Maintain Active Sites