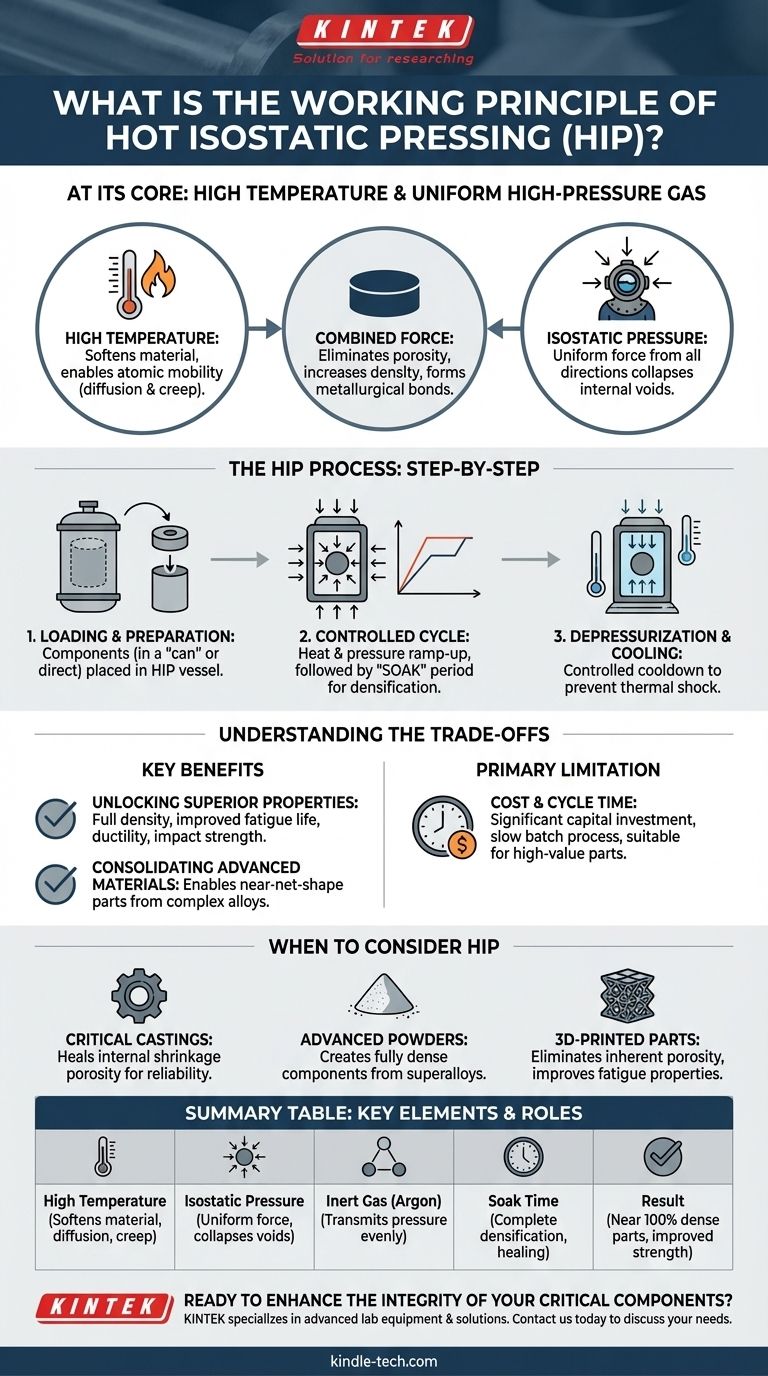

At its core, hot isostatic pressing (HIP) is a manufacturing process that uses high temperature and uniform, high-pressure gas to improve a material's properties. By subjecting a component to this environment, the process eliminates internal porosity and increases density, resulting in a stronger, more reliable final product. This principle applies to both consolidating metal or ceramic powders into a solid state and healing microscopic defects within pre-formed components.

The central principle of HIP is not just compression, but a combination of two forces. High temperature makes the material soft and allows its atoms to move, while extreme, uniform pressure provides the driving force to physically collapse internal voids and create metallurgical bonds across the newly closed gaps.

The Physics Behind HIP: Combining Heat and Pressure

To truly understand the HIP process, you must see it as the simultaneous application of heat and pressure, where each plays a distinct and critical role.

The Role of High Temperature

Heat is the enabler of change within the material. As a component is heated, typically to a significant fraction of its melting point, its atoms gain enough energy to become mobile.

This increased atomic mobility makes the material behave like a very stiff plastic. It allows for mechanisms like diffusion and creep, where atoms can move across surfaces and bond with each other, which is essential for healing internal voids.

The Principle of Isostatic Pressure

The term isostatic means the pressure is uniform and applied from all directions simultaneously. Imagine being deep in the ocean; the water pressure acts on you equally from every angle.

In a HIP system, this is achieved by filling a sealed, high-strength vessel with an inert gas, almost always argon. This gas is then pressurized to extreme levels, transmitting that pressure evenly onto every surface of the component inside. This uniformity ensures the part maintains its shape while being densified.

How Defects Are Eliminated

The combination of heat and pressure creates the ideal conditions for densification. The high, uniform pressure provides the physical force needed to collapse any internal gas-filled pores, voids, or microscopic cracks.

Simultaneously, the high temperature allows the atoms on opposite sides of these collapsing voids to diffuse and form strong, permanent metallurgical bonds. The result is a component that is theoretically 100% dense, with its internal structure healed and its mechanical integrity vastly improved.

The HIP Process Step-by-Step

A typical HIP cycle is a precisely controlled batch process managed by computers to ensure consistent results.

Loading and Preparation

Components are loaded into the cylindrical chamber of the HIP vessel. If the goal is to consolidate a powder, it must first be sealed within a gas-tight metal container, or "can," to which the pressure will be applied.

For densifying solid parts (like a casting or 3D-printed component), they can be loaded directly, as the pressure only needs to act on the exterior to collapse internal voids.

The Controlled Cycle

The process begins by heating the chamber and gradually increasing the gas pressure according to a pre-programmed recipe. The temperature, pressure, and time are tailored to the specific material and the desired outcome.

The components are then held at the target temperature and pressure for a "soak" period, which can last for several hours. This is the stage where the material consolidates and defects are healed.

Depressurization and Cooling

After the soak time is complete, the vessel is slowly cooled and the pressure is carefully released. A controlled cooldown is critical to prevent thermal shock to the newly densified parts. Once at a safe temperature, the chamber is opened and the components are removed.

Understanding the Trade-offs

While powerful, the HIP process is not a universal solution. Understanding its benefits and limitations is key to using it effectively.

Key Benefit: Unlocking Superior Properties

HIP is the definitive method for achieving full theoretical density. This directly translates to significant improvements in mechanical properties like fatigue life, ductility, and impact strength, making parts more reliable in critical applications.

Key Benefit: Consolidating Advanced Materials

The process is essential for powder metallurgy, enabling the creation of fully dense, near-net-shape parts from advanced alloys that are difficult or impossible to produce via traditional casting.

The Primary Limitation: Cost and Cycle Time

HIP equipment is a significant capital investment, and the process itself is slow. The long cycle times make it a batch process that is not suitable for high-volume, low-cost commodity parts. Its use is almost exclusively reserved for high-value, performance-critical components.

When to Consider Hot Isostatic Pressing

The decision to use HIP should be driven by a clear performance or quality objective.

- If your primary focus is eliminating defects in critical castings: HIP is the industry-standard solution for healing internal shrinkage porosity to maximize the part's reliability and service life.

- If your primary focus is creating net-shape parts from advanced powders: HIP is an enabling technology for producing fully dense components from materials like superalloys or metal matrix composites.

- If your primary focus is increasing the performance of a 3D-printed metal part: HIP is a common post-processing step used to eliminate the inherent porosity from additive manufacturing, drastically improving fatigue properties.

Ultimately, hot isostatic pressing is a tool for achieving the highest possible material integrity when performance cannot be compromised.

Summary Table:

| Key Element | Role in HIP Process |

|---|---|

| High Temperature | Softens material, enabling atomic diffusion and creep for bonding. |

| Isostatic Pressure | Applies uniform force from all directions to collapse internal voids. |

| Inert Gas (Argon) | Transmits pressure evenly within the sealed vessel. |

| Soak Time | Allows for complete densification and defect healing. |

| Result | Near 100% dense parts with improved strength and reliability. |

Ready to enhance the integrity of your critical components?

KINTEK specializes in advanced lab equipment and consumables, including solutions for material testing and processing. Our expertise in technologies like hot isostatic pressing can help you achieve superior material density and performance for your high-value applications.

Contact us today to discuss how we can support your laboratory's specific needs and drive your innovations forward.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Cylindrical Press Mold with Scale for Lab

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is the HIP process of casting? Transform Castings into High-Performance Components

- What is hot isostatic pressing treatment porosity? Achieve 100% Material Density for Critical Components

- Why is Hot Isostatic Pressing (HIP) Required for Additive Inconel 718? Achieve 100% Theoretical Density

- What is the scale of hot isostatic pressing? From Lab Research to Industrial Production

- What are the advantages of HIP over conventional PM? Achieve Full Density for Superior Performance

- What is the sinter HIP process? Achieve Near-Perfect Density in a Single Cycle

- Is hot isostatic pressing expensive? Invest in Unmatched Material Integrity for Critical Parts

- How does Hot Isostatic Pressing (HIP) enhance CuNiCoZnAlTi properties? Achieve Theoretical Density & Maximum Strength