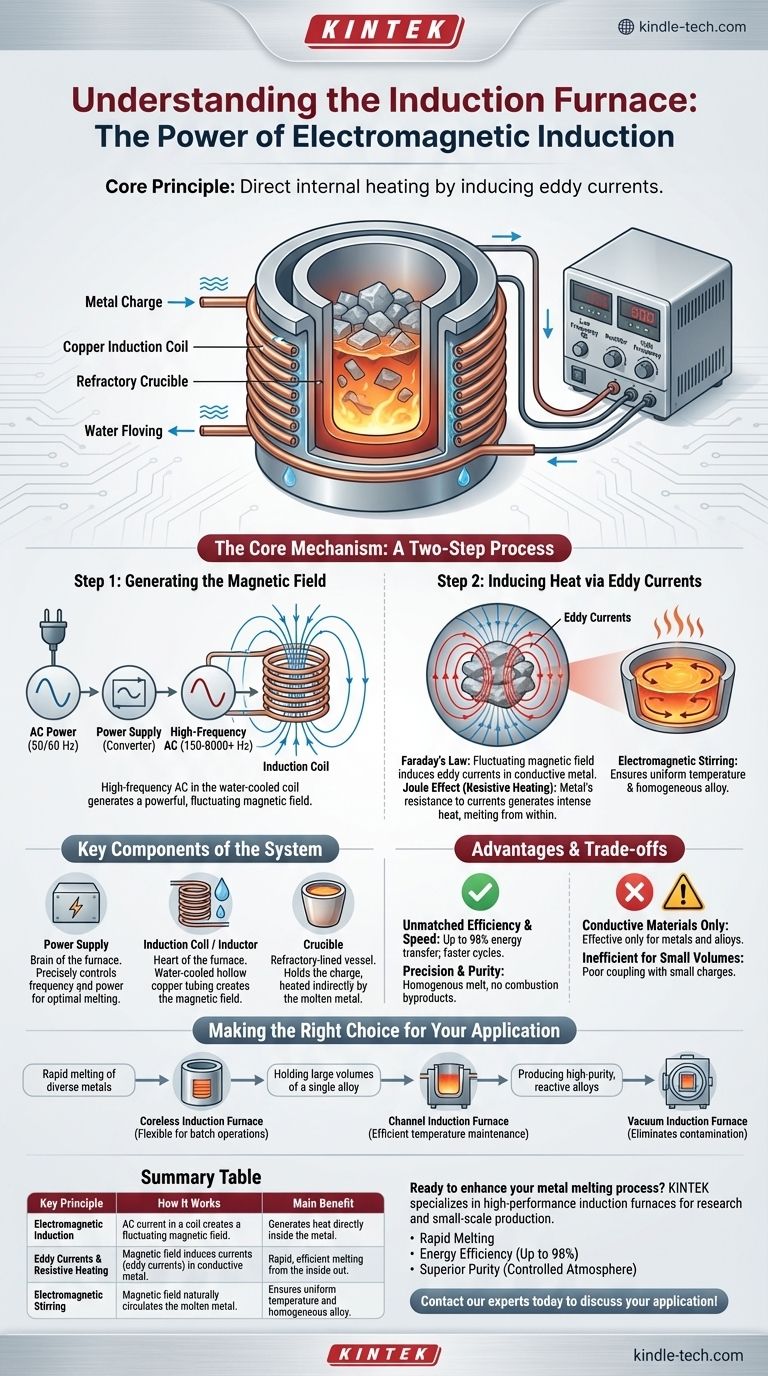

At its core, an induction furnace operates on the principle of electromagnetic induction. A powerful alternating current flows through a copper coil, creating a strong, fluctuating magnetic field. When a conductive material like metal is placed within this field, the field induces internal electrical currents—known as eddy currents—within the metal itself. The metal's natural resistance to the flow of these currents generates intense heat, rapidly causing the metal to melt from the inside out.

The fundamental advantage of an induction furnace is its ability to turn the metal itself into the heat source. Unlike conventional furnaces that heat externally, this direct internal heating provides exceptional speed, energy efficiency, and control over the melting process.

The Core Mechanism: A Two-Step Process

Understanding the working principle requires looking at two distinct but connected physical phenomena. The entire system is designed to execute these two steps with maximum efficiency.

Step 1: Generating the Magnetic Field

The process begins with the power supply. A standard three-phase electrical supply is converted from a low frequency (e.g., 50/60 Hz) to a much higher frequency, typically ranging from 150 Hz to 8,000 Hz or more.

This high-frequency alternating current is then directed into a hollow copper coil, often cooled with circulating water. As the current rapidly alternates direction, it generates a powerful and fluctuating magnetic field in the space within and around the coil, where the metal charge is located.

Step 2: Inducing Heat via Eddy Currents

This is where Faraday's Law of Induction comes into play. The fluctuating magnetic field passing through the conductive metal induces a circular flow of electrons, creating the eddy currents.

These currents are the key to the heating process. Due to the Joule effect (also known as resistive heating), the metal's inherent electrical resistance opposes the flow of these powerful eddy currents. This opposition releases thermal energy—heat—directly within the mass of the metal, causing its temperature to rise quickly.

A secondary benefit of this process is a natural electromagnetic stirring action. The forces generated by the eddy currents and magnetic field cause the molten metal to circulate, ensuring a uniform temperature and a homogenous alloy composition.

The Key Components of the System

An induction furnace is not just a coil but an integrated system. Each component plays a critical role.

The Power Supply

This is the brain of the furnace. It takes grid power and uses rectifiers and inverters to produce a high-frequency alternating current. The ability to precisely control this frequency and power output gives operators fine-grained control over the melting rate and temperature.

The Induction Coil (Inductor)

The inductor is the heart of the furnace. It's almost always made of hollow copper tubing to allow for water cooling, which is necessary to handle the immense electrical currents without overheating the coil itself. Its shape and size are engineered to maximize the magnetic field's coupling with the metal charge.

The Crucible

This is the refractory-lined vessel that contains the metal. It must be able to withstand extreme temperatures without reacting with the molten charge. Crucially, the crucible itself is not directly heated by the induction field; it only gets hot from contact with the molten metal.

Understanding the Trade-offs and Advantages

No technology is perfect for every application. The strengths of induction heating also define its limitations.

Advantage: Unmatched Efficiency and Speed

Because heat is generated directly within the material to be melted, energy transfer is extremely efficient, often reaching up to 98%. This minimizes thermal loss to the surrounding environment and enables much faster melting cycles compared to fuel-fired or arc furnaces.

Advantage: Precision and Purity

The electromagnetic stirring action ensures a homogenous melt, which is critical for creating high-quality alloys. Furthermore, because there is no combustion, there are no byproducts to contaminate the metal. When operated in a controlled atmosphere or vacuum, an induction furnace can produce exceptionally pure metals.

Limitation: Conductive Materials Only

The entire principle relies on inducing electrical currents within the charge. Therefore, induction furnaces are only effective for melting electrically conductive materials, primarily metals and their alloys.

Pitfall: Inefficient for Small Volumes

Induction furnaces are most efficient when the crucible is filled to an optimal level. Operating with a very small charge can lead to poor magnetic coupling and reduced energy efficiency, making them less ideal for very small, intermittent batches.

Making the Right Choice for Your Application

The specific design of an induction furnace is tailored to its intended purpose. Understanding your primary goal is key to selecting the correct type.

- If your primary focus is rapid melting of diverse metals: A coreless induction furnace, where the coil surrounds a simple crucible, offers the most flexibility for batch operations.

- If your primary focus is holding large volumes of a single alloy: A channel induction furnace, which operates like a transformer, is highly efficient for maintaining temperature in large-volume applications.

- If your primary focus is producing high-purity, reactive alloys: A vacuum induction furnace is the definitive choice, as it eliminates atmospheric contamination and ensures the highest material integrity.

By mastering the principle of direct, internal heating, the induction furnace provides a level of control and quality that is difficult to achieve with any other method.

Summary Table:

| Key Principle | How It Works | Main Benefit |

|---|---|---|

| Electromagnetic Induction | AC current in a coil creates a fluctuating magnetic field. | Generates heat directly inside the metal. |

| Eddy Currents & Resistive Heating | The magnetic field induces currents (eddy currents) in the conductive metal, generating heat. | Rapid, efficient melting from the inside out. |

| Electromagnetic Stirring | The magnetic field naturally circulates the molten metal. | Ensures a uniform temperature and homogeneous alloy. |

Ready to enhance your metal melting process with the precision and efficiency of an induction furnace?

At KINTEK, we specialize in high-performance lab equipment, including induction furnaces tailored for research, quality control, and small-scale production. Our solutions deliver:

- Rapid Melting: Significantly reduce cycle times with direct internal heating.

- Energy Efficiency: Achieve up to 98% energy transfer, lowering operational costs.

- Superior Purity: Melt in a controlled atmosphere to prevent contamination and create high-integrity alloys.

Whether you're working with ferrous, non-ferrous, or reactive metals, KINTEK has the right furnace for your laboratory's needs.

Contact our experts today to discuss your application and find the perfect induction furnace for your lab.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How is temperature controlled in a furnace? Mastering Precise Thermal Management

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing