The yield of pyrolysis from tires typically includes several key products: carbon black, pyrolysis oil, steel, and gas. From one ton of tires, the process yields approximately 380kg of carbon black, 300kg of pyrolysis oil, 170kg of steel, and 150kg of gas, which contains about 40% methane. These products have various industrial applications, making tire pyrolysis a valuable process for waste management and resource recovery.

Key Points Explained:

-

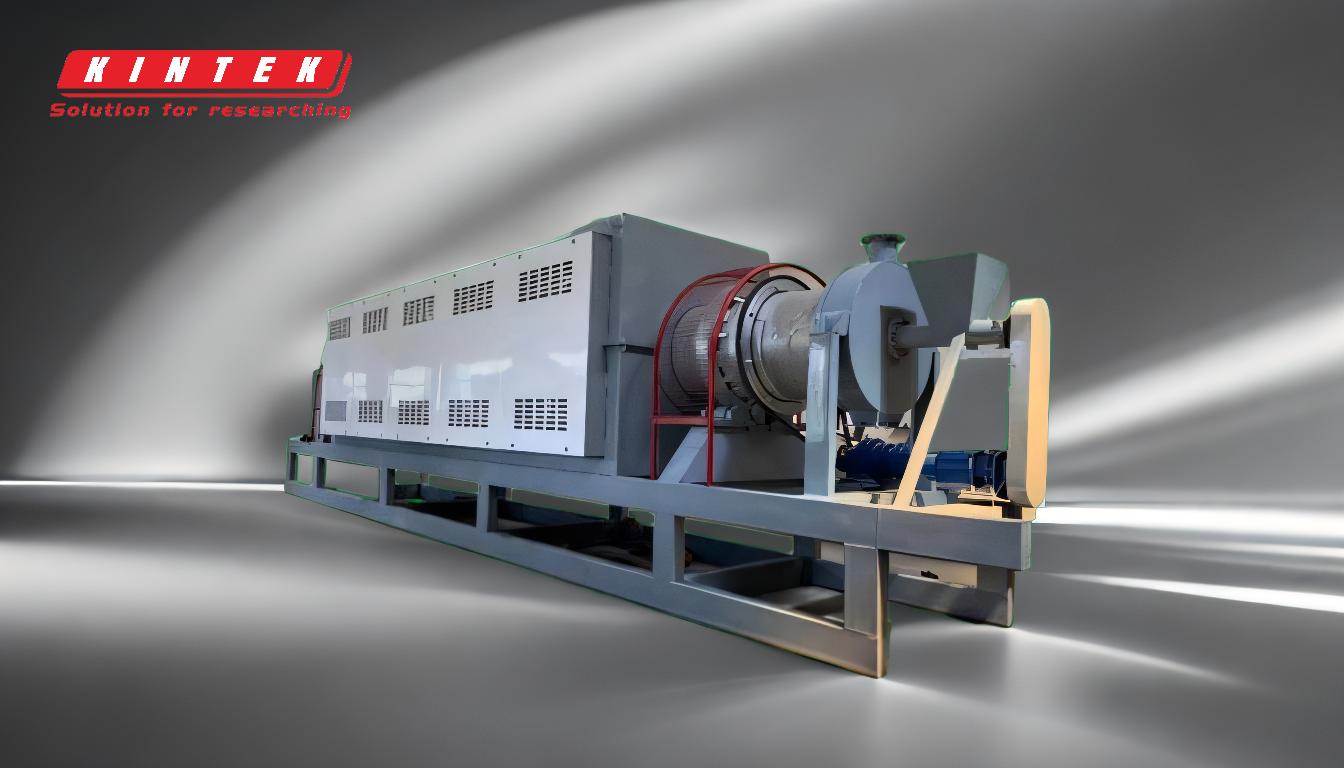

Types of Pyrolysis Reactors:

- The horizontal type pyrolysis reactor is recommended for processing tires and plastics. This type of reactor offers higher efficiency, better environmental performance, and ensures even heating of materials, which is crucial for a consistent yield of pyrolysis products.

-

Products of Tire Pyrolysis:

- Carbon Black: Approximately 380kg of carbon black is produced from one ton of tires. Carbon black is widely used in the manufacture of tires, rubber products, inks, and coatings.

- Pyrolysis Oil: About 300kg of pyrolysis oil is obtained. This oil is utilized in various industries such as cement kilns, paper mills, power plants, and industrial furnaces due to its high calorific value, low ash, low residual carbon, and low sulphur content.

- Steel: Around 170kg of steel is recovered from the tires. This steel can be recycled and used in various manufacturing processes.

- Gas: The process yields about 150kg of gas, which contains approximately 40% methane. This gas can be used as a fuel or further processed for chemical production.

-

Applications of Pyrolysis Products:

- Pyrolysis Oil: Besides being used as a biofuel, pyrolysis oil can serve as a feedstock for refining crude oil or producing chemical products.

- Syngas: The non-condensable gases produced, including hydrogen, methane, and various hydrocarbons, can be used as syngas for energy generation or as raw materials in chemical synthesis.

-

Environmental and Economic Benefits:

- The pyrolysis of tires not only helps in waste reduction but also turns waste into valuable resources, contributing to a circular economy.

- The process is environmentally friendly as it reduces the amount of waste tires in landfills and decreases the dependency on virgin materials by recycling the steel and carbon black.

-

Efficiency and Performance:

- The choice of reactor plays a significant role in the efficiency of the pyrolysis process. The horizontal reactor's ability to evenly heat the materials ensures a more uniform and efficient breakdown of tires into their constituent products.

This detailed breakdown highlights how tire pyrolysis is not only a method for waste management but also a significant contributor to resource recovery and environmental sustainability.

Summary Table:

| Product | Yield (Per Ton of Tires) | Key Applications |

|---|---|---|

| Carbon Black | 380kg | Tires, rubber products, inks, coatings |

| Pyrolysis Oil | 300kg | Cement kilns, paper mills, power plants |

| Steel | 170kg | Manufacturing processes, recycling |

| Gas | 150kg (40% methane) | Fuel, chemical production |

Unlock the potential of tire pyrolysis for your waste management needs—contact us today!