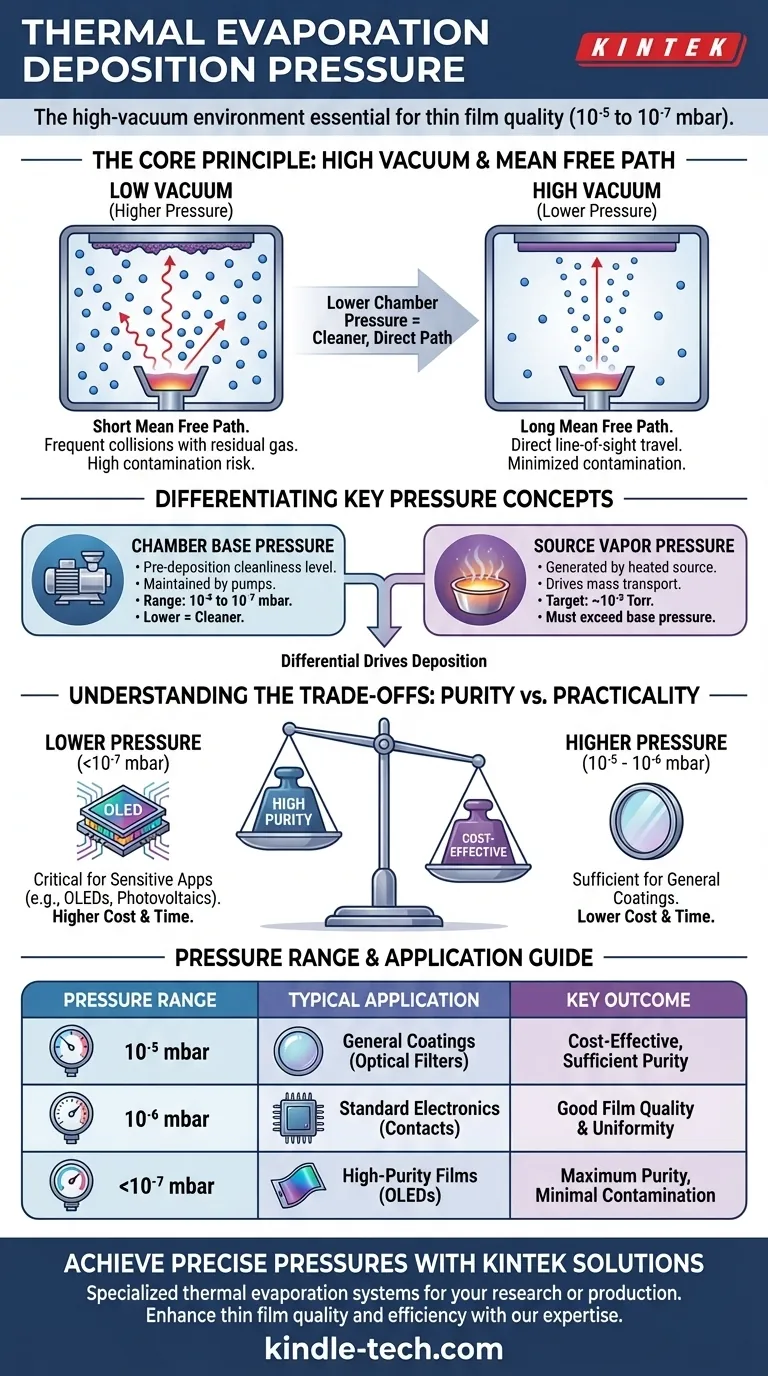

In thermal evaporation, the deposition pressure refers to the high-vacuum environment created within the process chamber, which is essential for the quality of the final thin film. This pressure is typically maintained in the range of 10⁻⁵ to 10⁻⁷ mbar (approximately 10⁻⁵ to 10⁻⁷ Torr), though the specific value depends on the material being deposited and the required purity of the film.

The core principle is straightforward: a lower chamber pressure creates a cleaner and more direct path for evaporated material to travel from the source to the substrate. This pressure is the fundamental parameter that dictates the purity, density, and overall performance of the deposited thin film.

The Critical Role of High Vacuum

Thermal evaporation is a physical vapor deposition (PVD) technique where a source material is heated in a vacuum until it evaporates. These vapor particles then travel through the chamber and condense onto a cooler substrate, forming a thin film. The chamber pressure is not a passive variable; it actively controls the outcome of this process.

Ensuring a "Mean Free Path"

A primary reason for creating a high vacuum is to increase the mean free path—the average distance a vapor particle can travel before colliding with another gas molecule.

In a low vacuum (higher pressure), the chamber is filled with residual gas molecules like nitrogen, oxygen, and water vapor. Evaporated source particles will collide with these molecules, scattering them and preventing them from reaching the substrate in a direct line-of-sight path.

By pumping the chamber down to a high vacuum (low pressure), we remove these obstacles. This ensures the evaporated material travels unimpeded from the source to the substrate, leading to a more uniform and dense film.

Minimizing Film Contamination

Any residual gas molecules in the chamber can become trapped within the growing film or react with the deposited material. This contamination can severely degrade the film's properties.

For example, reactive gases like oxygen can oxidize a metal film as it forms, changing its electrical and optical characteristics. This is especially critical in sensitive applications like the fabrication of OLEDs and organic photovoltaics, where film purity is paramount for device performance. A lower base pressure directly translates to a purer film.

Differentiating Key Pressure Concepts

The term "pressure" can refer to two distinct things in a thermal evaporation system. Understanding the difference is key to mastering the process.

Chamber Base Pressure

This is the pressure achieved inside the vacuum chamber before the deposition process begins. It is created by vacuum pumps and represents the starting level of cleanliness.

This is the pressure typically quoted in process recipes, with values between 10⁻⁵ and 10⁻⁷ mbar. A lower base pressure indicates fewer background gas molecules and a cleaner environment.

Source Vapor Pressure

This is the pressure generated by the evaporated source material itself when it is heated. For a material to evaporate or sublime effectively, its vapor pressure must significantly exceed the chamber's base pressure.

A common target vapor pressure for the source material during deposition is around 10⁻² Torr. This pressure differential is what drives the mass transport of material from the source crucible to the substrate.

Understanding the Trade-offs

Choosing the right deposition pressure involves balancing quality requirements against practical constraints. There is no single "best" pressure for every application.

Purity vs. Cost and Time

Achieving an ultra-high vacuum (UHV) in the range of 10⁻⁹ Torr or lower produces exceptionally pure films. However, reaching these pressures requires more sophisticated and expensive pumps, as well as significantly longer pump-down times.

For many industrial applications, a high-vacuum level of 10⁻⁶ Torr is a practical compromise, offering good film quality without the extreme cost and time investment of a UHV system.

Material and Application Sensitivity

The required base pressure is highly dependent on the material being deposited and its final use.

Coating a simple, non-reactive metal like gold for decorative purposes may only require a moderate vacuum. In contrast, depositing a reactive material like aluminum or a sensitive organic compound for an electronic device demands a much lower base pressure to prevent oxidation and ensure performance.

Setting the Right Pressure for Your Goal

Your choice of pressure should be driven by the specific outcome you need to achieve. Use the following as a guide.

- If your primary focus is maximum film purity (e.g., OLEDs, research-grade devices): Aim for the lowest base pressure your system can practicably achieve, ideally 10⁻⁷ mbar or lower, to minimize contamination.

- If your primary focus is general-purpose coating (e.g., simple metal contacts, optical filters): A moderate base pressure in the 10⁻⁵ to 10⁻⁶ mbar range is often a cost-effective and sufficient target.

- If you are experiencing poor film quality or inconsistent results: Insufficient vacuum is a primary suspect; verify your chamber's integrity and the performance of your vacuum pumps.

Ultimately, controlling the deposition pressure is about controlling the environment where your film is born.

Summary Table:

| Pressure Range | Typical Application | Key Outcome |

|---|---|---|

| 10⁻⁵ mbar | General-purpose metal coatings, optical filters | Cost-effective, sufficient purity |

| 10⁻⁶ mbar | Standard electronic contacts, research | Good film quality and uniformity |

| 10⁻⁷ mbar or lower | High-purity films (OLEDs, photovoltaics), sensitive materials | Maximum purity, minimal contamination |

Struggling with film purity or inconsistent deposition results? The right vacuum environment is critical. At KINTEK, we specialize in high-performance lab equipment, including thermal evaporation systems designed to achieve and maintain the precise pressures your research or production demands. Whether you're developing next-generation OLEDs or require reliable general-purpose coatings, our expertise ensures your process is optimized for success.

Contact our experts today to discuss your specific needs and discover how KINTEK's solutions can enhance your thin film quality and efficiency.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the difference between sputtering and evaporation techniques? A Guide to Choosing the Right PVD Method

- What is vacuum thin-film deposition? The Key to Advanced Surface Engineering

- What is the tooling factor of e-beam evaporation? Master Precise Thin-Film Control

- Is sputtering better than evaporation purity? A Guide to High-Quality Thin-Film Deposition

- What is the source of vacuum evaporation? Energy and Vacuum for High-Purity Coatings

- What is the process of thermal evaporation thin film deposition? A Guide to Simple, Cost-Effective PVD

- What precautions should be taken during evaporation process? Ensure High-Quality Film Deposition

- What is an example of thermal evaporation? Creating Reflective Headlight Coatings and More