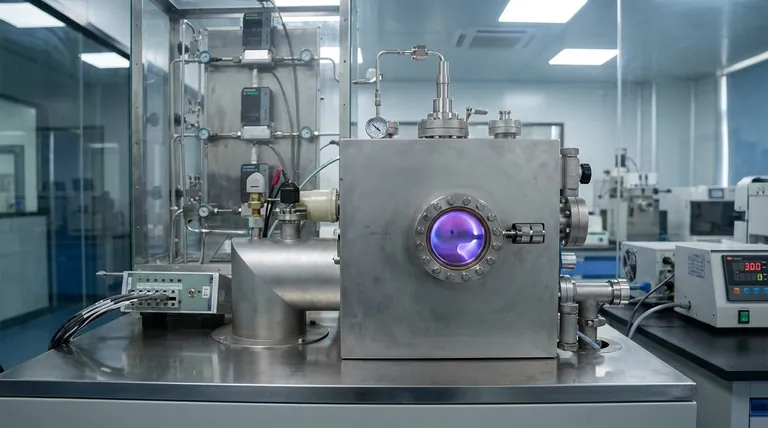

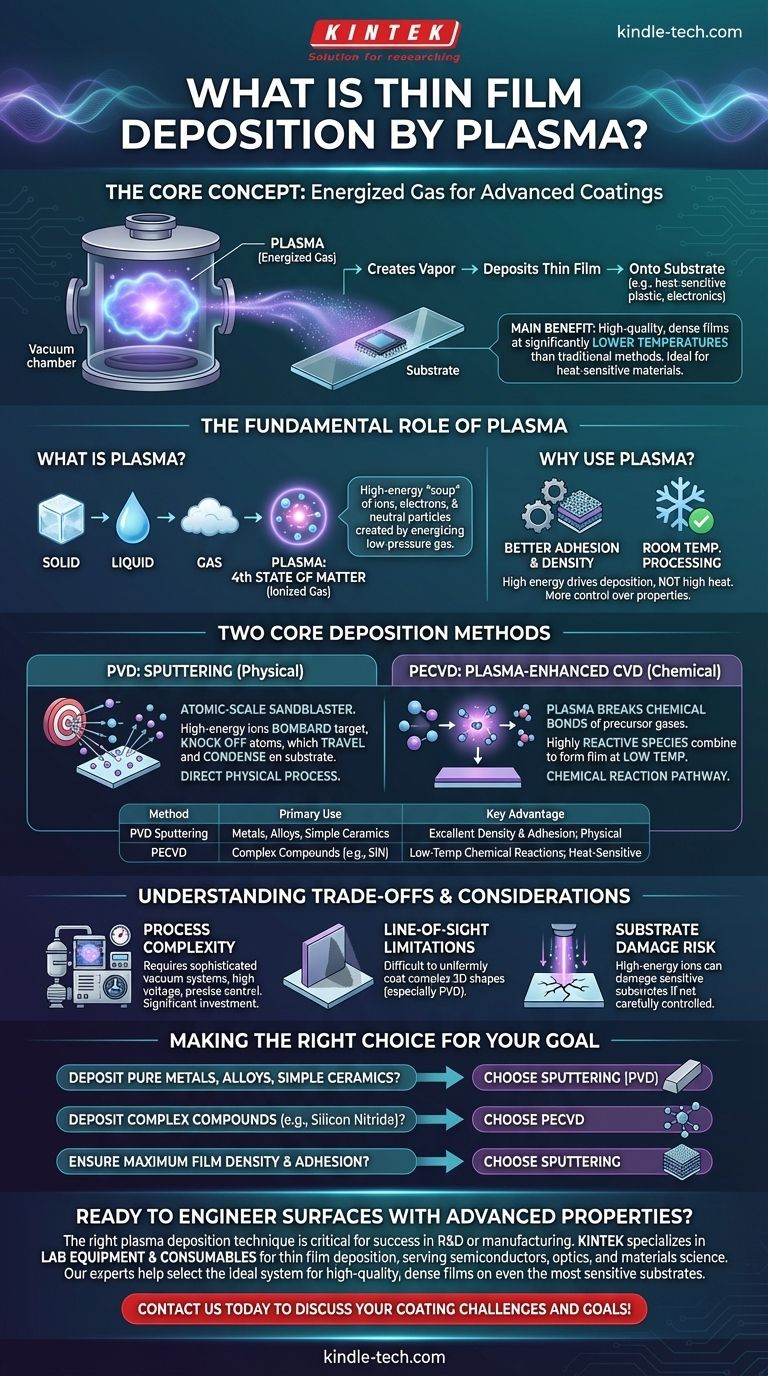

In plasma-based thin film deposition, an energized gas, or plasma, is the primary tool used to create a vapor of coating material and deposit it as an extremely thin layer onto a substrate's surface. This technique is a crucial sub-category of the two main deposition families, Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), and is performed inside a highly controlled vacuum chamber. The use of plasma enables the creation of high-performance coatings that modify the substrate's electrical, optical, or mechanical properties.

The core advantage of using plasma is its ability to create high-quality, dense films at significantly lower temperatures than traditional thermal methods. This critical feature allows for the advanced coating of heat-sensitive materials like plastics, polymers, and complex electronic components without causing damage.

The Fundamental Role of Plasma

To understand plasma deposition, you must first understand why plasma is used at all. It is not just an alternative; it is an enabling technology for creating materials and properties that are otherwise difficult or impossible to achieve.

What Exactly is Plasma?

Plasma is often called the fourth state of matter, following solid, liquid, and gas. It is created by applying a strong electrical field to a low-pressure gas, which energizes the gas atoms and strips away their electrons.

The result is an ionized gas—a highly reactive mixture of positive ions, electrons, and neutral particles. This energized "soup" of particles can be precisely manipulated with electric and magnetic fields to perform work at the atomic level.

Why Use Plasma for Deposition?

Using a plasma environment provides distinct advantages over purely thermal processes. The high energy of the plasma particles, rather than high heat, drives the deposition.

This results in better film adhesion to the substrate, higher film density, and more control over the final film properties like hardness, stress, and stoichiometry. Most importantly, it allows the entire process to run at or near room temperature.

Two Core Plasma Deposition Methods

While there are many variations, most industrial plasma deposition techniques fall into two primary categories. The choice between them depends entirely on the desired film material and its required properties.

Physical Vapor Deposition (PVD): Sputtering

In sputtering, the plasma's role is purely physical. High-energy ions from the plasma are accelerated and directed at a source material, known as the "target."

Think of this as an atomic-scale sandblaster. The ions bombard the target with such force that they knock off, or "sputter," individual atoms. These vaporized atoms then travel through the vacuum chamber and condense on the substrate, building the thin film one atom at a time.

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

In PECVD, the plasma's role is chemical. Precursor gases are introduced into the vacuum chamber, but unlike traditional CVD, they are not broken down by high heat.

Instead, the energy from the plasma is used to break the chemical bonds in the precursor gases. This creates highly reactive chemical species that then combine on the substrate surface, forming a solid thin film. This avoids the thousands of degrees of heat often required in thermal CVD.

Understanding the Trade-offs and Considerations

While powerful, plasma-based deposition is a complex process with specific requirements and limitations that must be respected for a successful outcome.

Process Complexity

These are not simple benchtop procedures. Plasma deposition requires sophisticated vacuum systems, high-voltage power supplies, and precise mass-flow controllers for the gases. The equipment is a significant capital investment and requires specialized knowledge to operate and maintain.

Line-of-Sight Limitations

In PVD processes like sputtering, deposition is largely a line-of-sight phenomenon. The sputtered atoms travel in relatively straight lines, which can make it difficult to uniformly coat complex, three-dimensional shapes with sharp corners or deep trenches.

Potential for Substrate Damage

While plasma enables low-temperature processing, the high-energy ions can still cause damage to extremely sensitive substrates if the process is not carefully controlled. Managing ion energy is a critical parameter in optimizing any plasma deposition process.

Making the Right Choice for Your Goal

The decision to use a specific plasma technique is dictated by the end goal—the material you need to deposit and the properties you need to achieve.

- If your primary focus is depositing pure metals, alloys, or certain simple ceramics: Sputtering (PVD) is often the most direct and reliable method due to its physical nature.

- If your primary focus is depositing complex dielectric or semiconducting compounds like silicon nitride or amorphous silicon: PECVD provides the chemical reaction pathway needed to form these materials at low temperatures.

- If your primary focus is ensuring maximum film density and adhesion on a durable substrate: Sputtering is an excellent choice, as the energetic arrival of atoms promotes a dense film structure.

By understanding the distinct roles of plasma, you can select the precise deposition technique needed to engineer surfaces with advanced and highly specific properties.

Summary Table:

| Method | Primary Use | Key Advantage |

|---|---|---|

| PVD Sputtering | Depositing pure metals, alloys, simple ceramics | Excellent film density and adhesion; direct physical process |

| PECVD | Depositing complex compounds (e.g., silicon nitride) | Low-temperature chemical reactions; ideal for heat-sensitive materials |

Ready to engineer surfaces with advanced properties? The right plasma deposition technique is critical for your success in R&D or manufacturing. KINTEK specializes in lab equipment and consumables for thin film deposition, serving laboratories in semiconductors, optics, and materials science. Our experts can help you select the ideal system for depositing high-quality, dense films on even the most sensitive substrates. Contact us today to discuss your specific coating challenges and goals!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How are wafers and electrodes configured within a PECVD system? Mastering Parallel-Plate Architecture

- What is the role of a plasma reactor in cobalt ferrite synthesis? Enhance Magnetic Performance with Plasma Processing

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- What are the technical advantages of PECVD vs. CVD for CF2 films? Master Precision Nano-Engineering

- What is the chemical composition of DLC coating? It's a Family of Carbon-Based Materials

- How does radio frequency (RF) power affect the PECVD process? Master Ionization for Superior Thin Film Quality

- What gases are used in PECVD? A Guide to Functional Gas Mixtures for Thin-Film Deposition

- What is PECVD in solar cells? The Key to High-Efficiency Anti-Reflection and Passivation