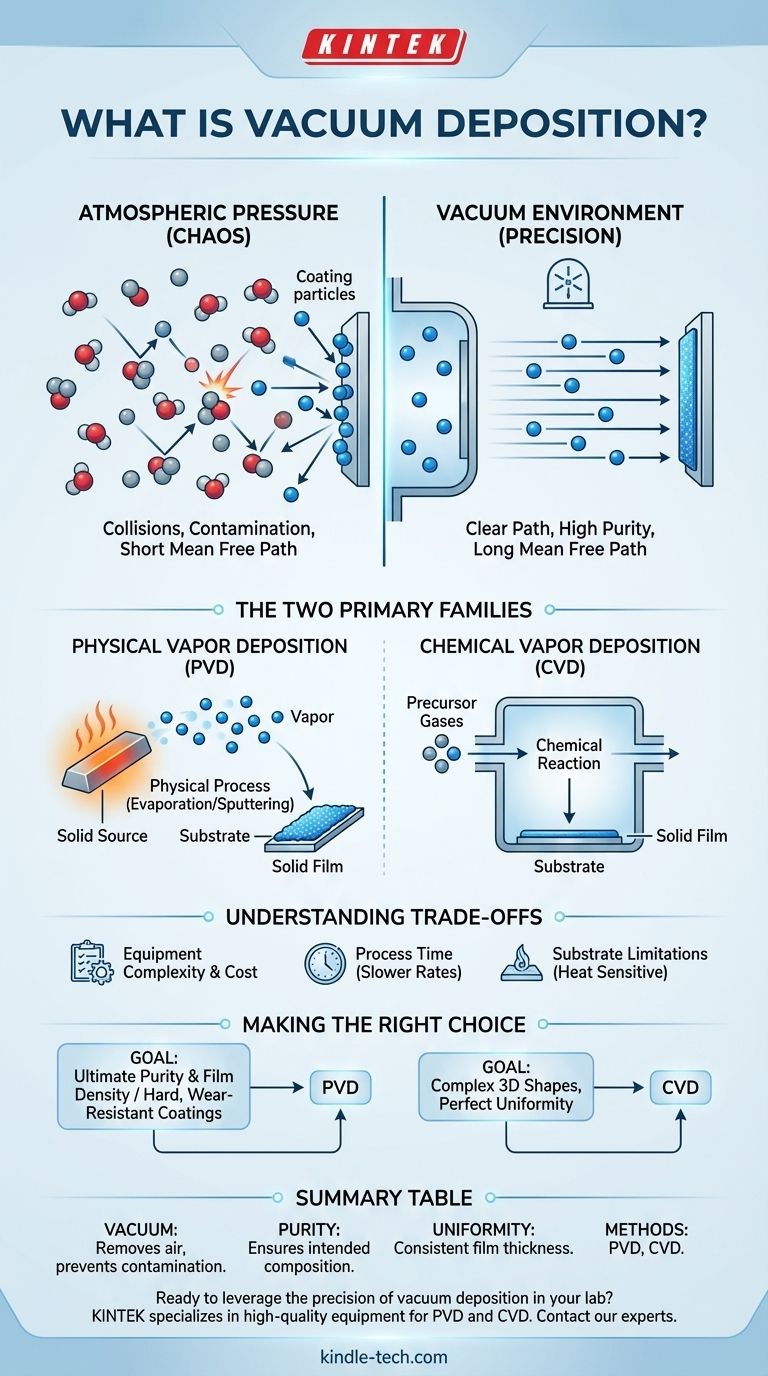

At its core, vacuum deposition is a family of processes used to apply extremely thin films of material onto a surface, atom by atom. This entire operation takes place inside a chamber where the air has been removed to create a vacuum, ensuring the coating is applied with exceptional precision and purity.

The critical insight is not the deposition process itself, but the role of the vacuum. The vacuum creates a pristine, unobstructed environment, allowing coating particles to travel directly to the target surface, resulting in a film that is fundamentally purer and more uniform than what is possible in open air.

Why a Vacuum is Essential for High-Quality Coatings

To understand vacuum deposition, you must first understand the problem it solves: interference from the air around us. The atmosphere is a dense sea of gas molecules that collide with everything, introducing contamination and chaos at the atomic scale.

Eliminating Collisions and Creating a Clear Path

At normal atmospheric pressure, the path of a vaporized particle is incredibly short—often less than a millimeter before it collides with an air molecule. This prevents the coating material from ever reaching its target effectively.

Creating a vacuum drastically reduces the density of these interfering atoms. This increases the mean free path, which is the average distance a particle can travel before a collision. In a high vacuum, this path can extend for many meters, allowing coating atoms to travel in a straight line from their source directly to the substrate.

Ensuring Unmatched Purity

The air contains reactive gases, primarily oxygen and water vapor. If these gases are present during the deposition process, they will react with the coating material and become embedded in the film as impurities.

This contamination can degrade the film's electrical, optical, or mechanical properties. The vacuum removes these undesirable gas atoms, ensuring the chemical composition of the final coating is exactly what was intended.

Enabling the Vaporization Process

Many of the techniques used to turn a solid material into a vapor can only function in a vacuum. Exposing a superheated material to the atmosphere would cause it to instantly oxidize or burn, preventing the creation of a pure vapor stream needed for the coating process.

The Two Primary Families of Vacuum Deposition

While there are many specific techniques, they generally fall into two major categories defined by how the material is transported to the surface.

Physical Vapor Deposition (PVD)

In PVD, the coating material starts as a solid. A physical process—like heating it until it evaporates or bombarding it with ions (sputtering)—is used to convert it into a vapor. This vapor then travels through the vacuum and condenses on the cooler substrate, forming a solid film.

Chemical Vapor Deposition (CVD)

In CVD, the process is chemical rather than physical. One or more volatile precursor gases are introduced into the vacuum chamber. These gases then react or decompose on the substrate's surface to produce the desired film. The vacuum allows for precise control over the pressure and purity of these reactant gases.

Understanding the Trade-offs

While vacuum deposition offers superior control and quality, it comes with practical considerations that are important to recognize.

Equipment Complexity and Cost

Creating and maintaining a high-vacuum environment requires sophisticated and often expensive equipment, including specialized chambers, pumps, and gauges. This represents a significant capital investment compared to atmospheric coating methods.

Process Time

Achieving a deep vacuum can be time-consuming, and deposition rates for building up thicker films can be relatively slow. This makes the process less suitable for applications where speed is more critical than atomic-level precision.

Substrate Limitations

Many vacuum deposition processes generate significant heat. This can limit the types of materials that can be coated, as some plastics or other sensitive substrates may not be able to withstand the processing temperatures without deforming.

Making the Right Choice for Your Goal

The decision to use vacuum deposition, and which specific method to choose, depends entirely on the desired outcome for the final product.

- If your primary focus is ultimate purity and film density: A PVD process in a high-vacuum environment is often the best choice, as it physically transports the source material with minimal chance for contamination.

- If your primary focus is coating complex 3D shapes with perfect uniformity: A low-pressure CVD (LPCVD) process is often superior, as the precursor gases can flow and react on all surfaces of an intricate part.

- If your primary focus is creating hard, wear-resistant coatings for tools: PVD techniques like sputtering are the industry standard for their durability and strong adhesion.

Ultimately, leveraging a vacuum environment provides an unparalleled level of control, transforming the chaotic nature of atoms into the precise art of thin-film engineering.

Summary Table:

| Key Aspect | Why It Matters in Vacuum Deposition |

|---|---|

| Vacuum Environment | Removes air molecules to prevent contamination and collisions. |

| Purity | Ensures the chemical composition of the coating is exactly as intended. |

| Uniformity | Allows atoms to travel in a straight line, creating a consistent film. |

| Primary Methods | Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). |

Ready to leverage the precision of vacuum deposition in your lab?

KINTEK specializes in providing the high-quality lab equipment and consumables needed for advanced coating processes like PVD and CVD. Whether you are developing next-generation electronics, durable tool coatings, or specialized optical films, our solutions ensure the purity and control your research demands.

Contact our experts today to discuss how we can support your specific laboratory needs and help you achieve superior thin-film results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications