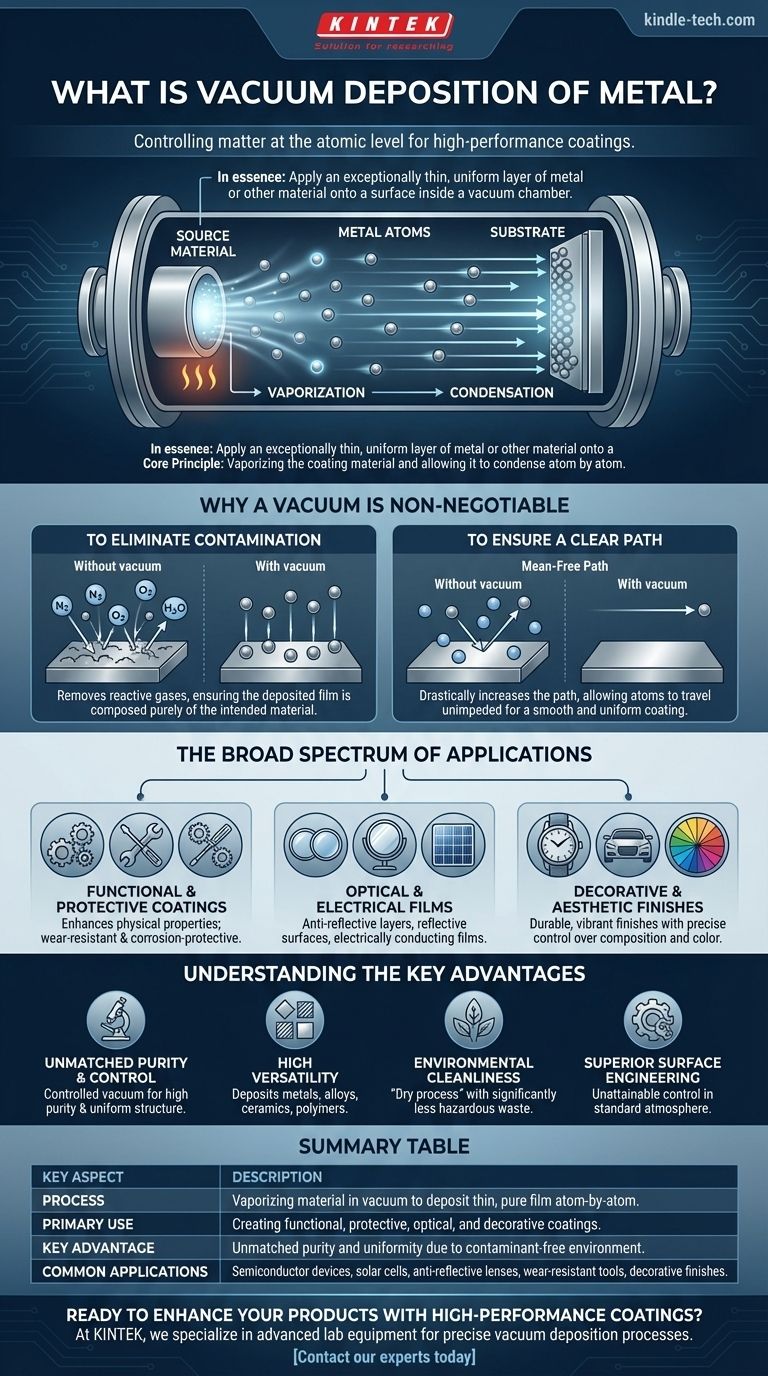

In essence, vacuum deposition is a family of high-tech manufacturing processes used to apply an exceptionally thin, uniform layer of metal or other material onto a surface. This is all done inside a vacuum chamber where the air has been removed. The core principle involves vaporizing the coating material and allowing it to condense atom by atom onto the target object, forming a high-performance film.

The critical insight is that vacuum deposition isn't just about coating an object; it's about controlling matter at the atomic level. By removing air and other gases, the process eliminates contamination and ensures the vaporized metal atoms travel in a straight line, resulting in films that are purer, denser, and more uniform than any conventional coating method can achieve.

Why a Vacuum is Non-Negotiable

The use of a vacuum is the defining feature of this process and serves two fundamental purposes that are impossible to achieve in a normal atmosphere.

To Eliminate Contamination

In a standard environment, surfaces are constantly bombarded by air molecules, primarily nitrogen, oxygen, and water vapor.

If you tried to deposit a highly reactive metal in the open air, it would instantly oxidize or form other compounds, creating an impure and weak film. The vacuum removes these reactive gases, ensuring the deposited film is composed purely of the intended material.

To Ensure a Clear Path

At atmospheric pressure, a vaporized atom can only travel a tiny distance before colliding with an air molecule. This is known as a short "mean-free path."

Creating a vacuum drastically increases this path, allowing the vaporized metal atoms to travel directly from the source to the target substrate without interference. This unimpeded travel is essential for building a smooth and uniform coating.

The Broad Spectrum of Applications

The precision of vacuum deposition makes it indispensable for creating specialized coatings across numerous industries where performance is critical.

Functional & Protective Coatings

The most common use is to enhance the physical properties of a substrate. This includes creating extremely hard, wear-resistant coatings for cutting tools or engine parts.

It is also widely used for corrosion-protective coatings, replacing less environmentally friendly processes like cadmium or chromium electroplating.

Optical & Electrical Films

Vacuum deposition is used to create highly specialized optical coatings on lenses, such as anti-reflective layers. It's also the primary method for producing the reflective surfaces on mirrors and for creating the thin, electrically conducting films used in semiconductor devices and solar cells.

Decorative & Aesthetic Finishes

By precisely controlling the film's composition, a wide range of durable and vibrant decorative finishes can be achieved.

Hybrid processes can deposit materials like titanium carbonitride, producing a spectrum of colors from gold to purple to black for applications on watches, tools, and automotive trim.

Understanding the Key Advantages

Choosing vacuum deposition over other methods is a decision driven by the need for quality, performance, and environmental responsibility.

Unmatched Purity and Control

Because the process occurs in a controlled vacuum, the resulting films have exceptionally high purity and a uniform structure. This level of control is what enables the creation of high-performance electronic and optical devices.

High Versatility

The technique can be used to deposit a vast range of materials, including metals, alloys, ceramics, and even some polymers, onto an equally wide range of substrates.

Environmental Cleanliness

Vacuum deposition is considered a "dry process." It produces significantly less hazardous waste compared to wet chemical processes like electroplating, making it a more ecologically sound choice. This is often a major factor in its adoption.

Making the Right Choice for Your Goal

Consider vacuum deposition when the surface properties of your component are as critical as its bulk material.

- If your primary focus is high performance: Use vacuum deposition for applications like semiconductors, optical lenses, or aerospace components where film purity and uniformity are paramount.

- If your primary focus is durability: This is the ideal process for creating wear-resistant coatings on tools and machinery or for applying robust corrosion protection.

- If your primary focus is aesthetics with function: Choose this method for creating vibrant, hard-wearing decorative coatings that outperform traditional paints or plating.

- If your primary focus is environmental compliance: Vacuum deposition provides a powerful alternative to traditional plating methods that involve hazardous chemicals.

Ultimately, vacuum deposition provides a level of control over surface engineering that is simply unattainable in a standard atmosphere.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Vaporizing a material in a vacuum to deposit a thin, pure film atom-by-atom onto a substrate. |

| Primary Use | Creating functional, protective, optical, and decorative coatings. |

| Key Advantage | Unmatched purity and uniformity due to the contaminant-free vacuum environment. |

| Common Applications | Semiconductor devices, solar cells, anti-reflective lenses, wear-resistant tools, decorative finishes. |

Ready to enhance your products with high-performance coatings?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise vacuum deposition processes. Whether you're developing cutting-edge electronics, durable industrial components, or high-quality optical systems, our solutions ensure the purity and uniformity your applications demand.

Contact our experts today to discuss how our vacuum deposition equipment can help you achieve superior surface engineering results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials