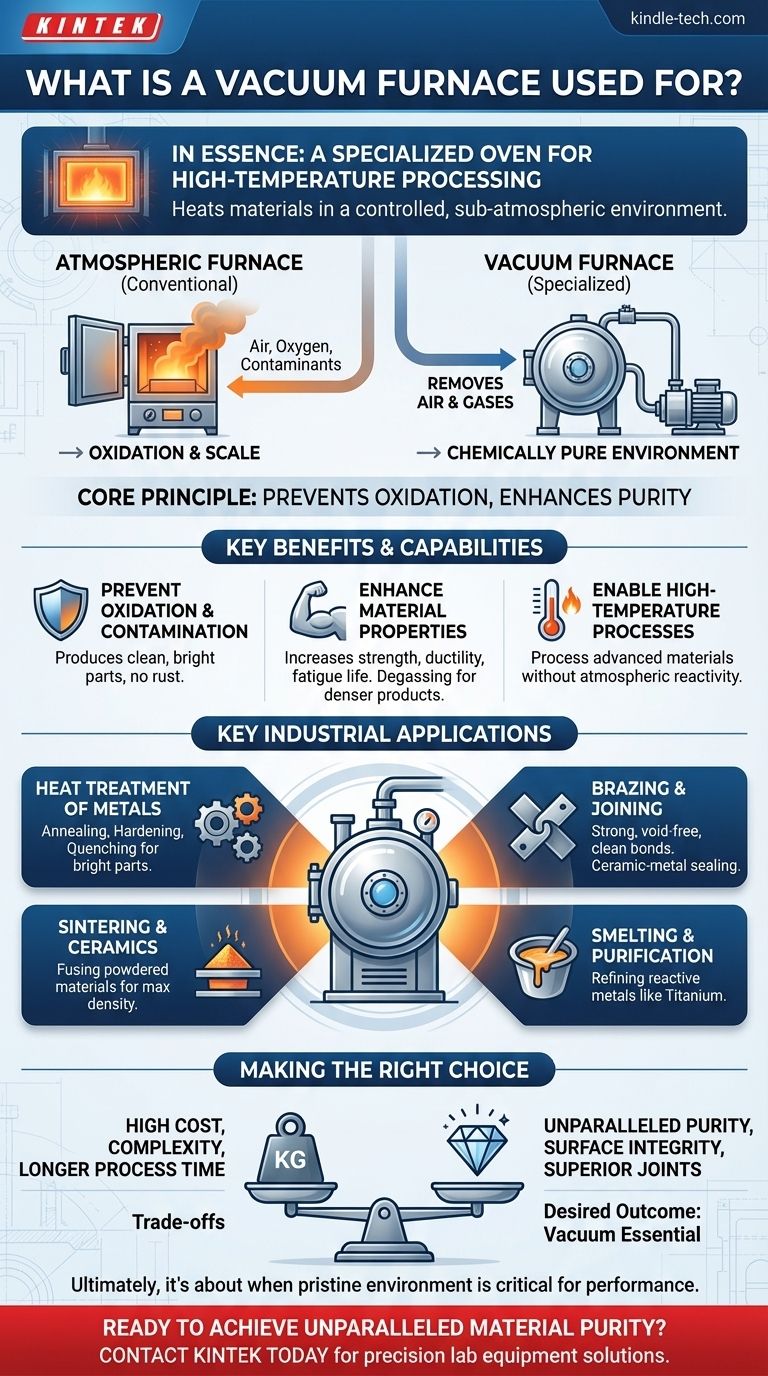

In essence, a vacuum furnace is a specialized oven for high-temperature processing. It is used for a wide range of industrial applications, including the heat treatment of metals, ceramic firing, brazing, and material science research. Its primary function is to heat materials to very high temperatures within a controlled, sub-atmospheric environment.

The true purpose of a vacuum furnace is not just to heat materials, but to create a chemically pure environment. By removing air and other atmospheric gases, it prevents unwanted reactions like oxidation, resulting in cleaner, stronger, and higher-performance materials.

The Core Principle: Why a Vacuum is Essential

A conventional furnace heats materials in the open atmosphere. A vacuum furnace first removes that atmosphere before heating begins. This fundamental difference is the key to its unique capabilities.

Preventing Oxidation and Contamination

At high temperatures, most metals react readily with oxygen in the air, forming a layer of oxide (rust or scale) on the surface. A vacuum removes the oxygen, protecting the material's surface integrity and chemical purity.

This process is like performing a delicate operation in a surgical cleanroom. By removing contaminants from the environment, you ensure the outcome is predictable and free of defects.

Enhancing Material Properties

Processing materials in a vacuum can significantly improve their final characteristics. For example, vacuum heat treatment can increase the strength, ductility, and fatigue life of metal alloys.

This controlled environment is also critical for degassing, a process that removes trapped gases from within a material. This leads to denser, less porous products with superior mechanical and electrical properties.

Enabling High-Temperature Processes

Many advanced materials and alloys require extremely high processing temperatures. At these temperatures, reactivity with the atmosphere increases dramatically.

A vacuum is often the only environment in which these materials can be successfully processed without being ruined by contamination.

Key Applications in Industrial Processes

The ability to create a clean, high-temperature environment makes vacuum furnaces indispensable across several high-tech industries, from aerospace to electronics.

Heat Treatment of Metals

This is one of the most common uses. Processes like annealing (softening metal), hardening (increasing strength), and quenching (rapid cooling) are performed in a vacuum to produce bright, clean parts that don't require subsequent cleaning.

Brazing and Joining

Vacuum brazing is a high-tech joining process used to create incredibly strong and clean bonds between components. The vacuum ensures the brazing alloy flows cleanly and wets the parent materials completely, creating a void-free joint.

This is also used for ceramic-metal sealing, a critical process for manufacturing components used in electronics and vacuum tubes.

Sintering and Ceramics

Sintering is the process of fusing powdered materials into a solid mass using heat. Performing this in a vacuum is essential for advanced ceramics and powdered metals (like tungsten carbide) to achieve maximum density and strength without impurities.

Smelting and Material Purification

Vacuum furnaces are used for melting and refining highly reactive metals like titanium and superalloys. The vacuum prevents these expensive materials from being contaminated by atmospheric gases during their liquid phase.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the solution for every heating application. Objectivity requires acknowledging their limitations.

Cost and Complexity

Vacuum furnaces are significantly more expensive to purchase, operate, and maintain than their atmospheric counterparts. They require complex vacuum pumps, control systems, and skilled operators.

Process Time

Achieving a high-quality vacuum takes time. The pump-down cycle can add considerable duration to the overall manufacturing process, potentially reducing throughput compared to simpler furnace types.

Material Limitations

Not all materials are suitable for vacuum processing. Materials with high vapor pressure can "outgas" excessively, meaning they turn into a gas and contaminate the furnace or the part itself.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace hinges on the desired outcome for your material.

- If your primary focus is material purity and surface integrity: A vacuum furnace is essential for preventing oxidation and producing a clean, bright finish on reactive metals.

- If your primary focus is creating the strongest possible joints: Vacuum brazing provides superior bond strength and reliability for critical components.

- If your primary focus is cost-effective, bulk heat treatment of non-reactive metals: A conventional atmospheric furnace is often the more practical and economical choice.

Ultimately, mastering thermal processing comes from understanding when the pristine environment of a vacuum is a critical requirement versus an unnecessary expense.

Summary Table:

| Application | Key Benefit |

|---|---|

| Heat Treatment | Prevents oxidation, produces clean, bright parts |

| Brazing | Creates strong, void-free joints |

| Sintering | Achieves maximum density in ceramics and metals |

| Material Purification | Refines reactive metals like titanium without contamination |

Ready to achieve unparalleled material purity and performance in your lab?

KINTEK specializes in precision lab equipment, including vacuum furnaces designed for demanding applications like heat treatment, brazing, and materials research. Our solutions help you prevent oxidation, enhance material properties, and ensure reliable, repeatable results.

Contact us today to discuss how a KINTEK vacuum furnace can meet your specific laboratory needs and drive your research forward.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a pit furnace? The Vertical Solution for Large, Heavy Parts

- What is the significance of maintaining a high vacuum environment during the sintering of ODS iron-based alloys?

- How does furnace cooling occur in the heat treatment process? A Guide to Controlled Slow Cooling

- Which furnace can produce high temperature? Choose the Right High-Temp Furnace for Your Process

- What is the purpose of a laboratory vacuum drying oven in catalyst post-processing? Preserve Activity & Pore Structure

- How are vacuum removal systems utilized during the synthesis of titanium alloy modification molecules? | KINTEK

- What is the process of an arc melting furnace? The Key to High-Volume Steel Scrap Recycling

- What role does a high-vacuum furnace environment play in W-Cu combustion synthesis? Ensure Defect-Free Density