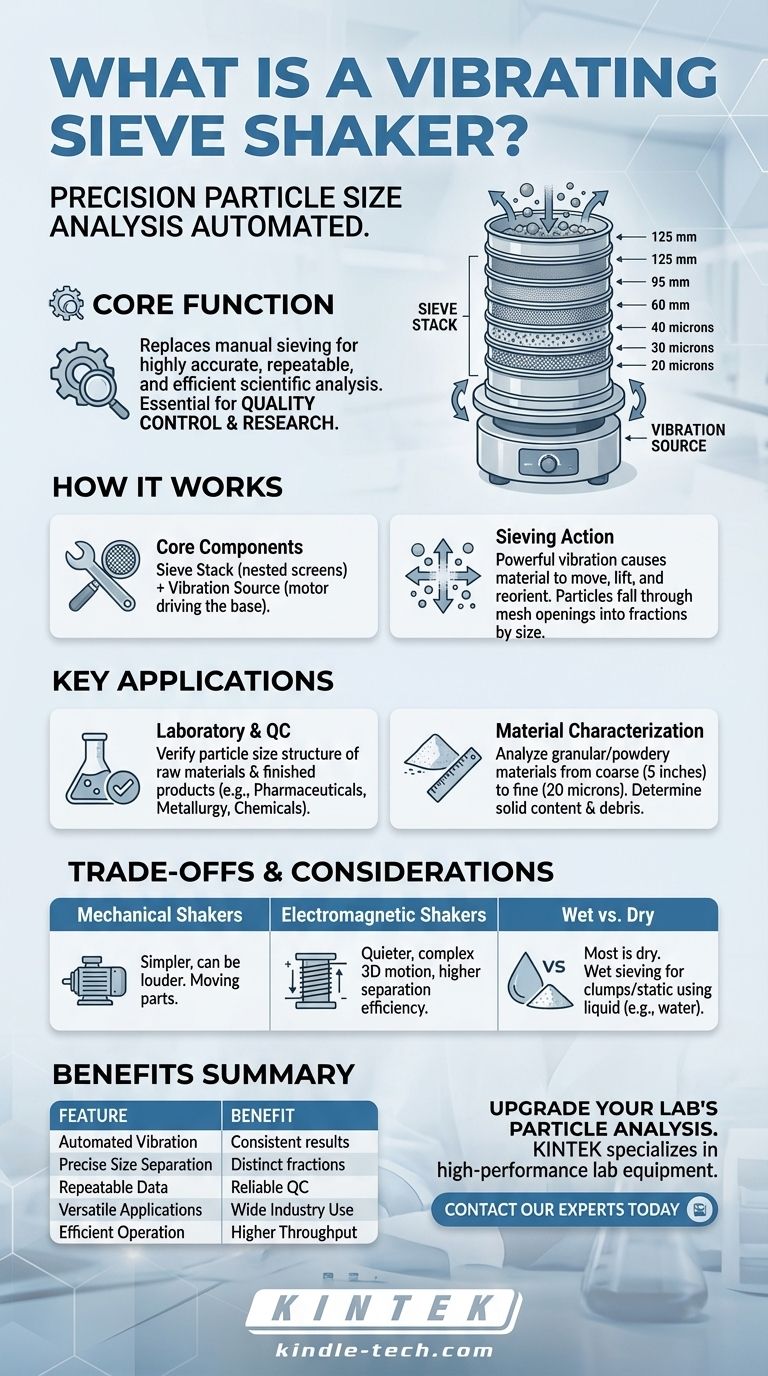

For any precise particle size analysis, a vibrating sieve shaker is the standard laboratory instrument used to separate granular or powdered materials. It replaces manual hand sieving by using a vibration motor to agitate a stack of test sieves, each with a specific mesh size. This automated process allows particles to systematically fall through the sieves until they are sorted into distinct size fractions.

The core function of a sieve shaker is to transform particle sizing from an inconsistent, manual task into a highly accurate, repeatable, and efficient scientific method. It provides the reliable data necessary for quality control, research, and production across numerous industries.

How a Sieve Shaker Achieves Separation

A sieve shaker’s effectiveness comes from the interplay between its components and the specific motion it generates. Understanding this mechanism is key to appreciating its role in material analysis.

The Core Components

The system is built from two primary parts: the sieve stack and the vibration source.

The sieve stack consists of multiple test sieves nested together. Each sieve is composed of a screen frame (typically stainless steel or brass), a precisely woven wire mesh with a specific opening size, and a skirt that allows them to stack securely.

The vibration source is usually an electric motor, either mechanical or electromagnetic, that drives the base of the shaker.

The Sieving Action

The motor imparts a powerful vibration to the entire sieve stack. This agitation causes the material sample placed in the top sieve to move continuously across the mesh.

Some advanced models, particularly electromagnetic sieve shakers, create a three-dimensional elliptical motion. This ensures particles are constantly lifted and reoriented, maximizing their chances of passing through the mesh openings if they are small enough.

Particles smaller than the top sieve's mesh fall to the sieve below it. This process repeats down the entire stack, effectively sorting the material by size until a final collection pan at the bottom catches the finest particles.

Key Applications and Use Cases

The ability to deliver fast and repeatable results makes sieve shakers indispensable tools in settings where material specifications are critical.

Laboratory and Quality Control

Sieve shakers are staples in quality inspection rooms and scientific research labs. They are used to accurately verify the particle size structure of raw materials and finished products.

This is crucial in industries like metallurgy, pharmaceuticals, geology, chemicals, and abrasives, where particle size directly impacts product performance, safety, and consistency.

Material Characterization

The primary use is for particle size analysis of granular and powdery materials. Sieve shakers can measure solid particles ranging from coarse materials as large as 125 mm (5 inches) down to fine powders as small as 20 microns (635 mesh).

They can also be used for determining liquid solid content and the amount of debris in a sample.

Understanding the Trade-offs and Considerations

While highly effective, the choice of shaker and method depends on your specific material and analysis goals.

Mechanical vs. Electromagnetic Shakers

Mechanical shakers are often simpler but can be louder due to their moving parts. Electromagnetic shakers are quieter and generate a more complex 3D motion, which can improve separation efficiency for certain materials.

Wet vs. Dry Sieving

Most sieving is done dry. However, wet sieve analysis is an option for materials that tend to clump or are affected by static electricity. This requires a liquid (usually water) to help disperse the particles, but it is only suitable if the material itself is not adversely affected by the liquid.

Accuracy and Repeatability

The primary advantage of a sieve shaker over manual methods is the elimination of operator-dependent variables. The consistent vibration and fixed timing ensure that results are highly repeatable, which is essential for valid scientific comparison and strict quality control.

Making the Right Choice for Your Analysis

Your specific needs will determine the best approach to using a sieve shaker.

- If your primary focus is process efficiency: A sieve shaker offers a dramatic speed increase over manual methods, allowing for higher throughput in a quality control environment.

- If your primary focus is data reliability: The automated and consistent motion of a shaker provides the repeatable results necessary for accurate research and stringent product verification.

- If you are working with very fine or agglomerated powders: Consider an electromagnetic shaker with 3D motion or a wet sieving process to ensure proper particle separation.

Ultimately, a vibrating sieve shaker empowers you to make informed decisions based on precise, dependable particle size data.

Summary Table:

| Feature | Benefit |

|---|---|

| Automated Vibration | Replaces manual sieving for consistent, operator-independent results |

| Precise Size Separation | Sorts particles from 125 mm down to 20 microns into distinct fractions |

| Repeatable Data | Essential for reliable quality control and scientific comparison |

| Versatile Applications | Used in pharmaceuticals, chemicals, metallurgy, geology, and more |

| Efficient Operation | Dramatically increases throughput compared to manual methods |

Upgrade your lab's particle analysis with KINTEK's precision sieve shakers.

Are you struggling with inconsistent manual sieving or need reliable data for your quality control? KINTEK specializes in high-performance lab equipment, including mechanical and electromagnetic sieve shakers designed for accuracy and efficiency.

We provide the right tools for your specific materials—whether you're analyzing coarse aggregates or fine, agglomerated powders. Our expertise ensures you get the repeatable results necessary for research and stringent product verification.

Let's optimize your particle size analysis. Contact our experts today to discuss your application and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the frequency of a vibrating screen? Unlock Optimal Material Separation Efficiency

- What is the amplitude of a sieve shaker? A Guide to Optimizing Particle Separation

- What is the principle of vibratory sieve shaker? Achieve Accurate Particle Size Analysis

- What is the use of vibratory sieve shaker? Achieve Precise Particle Size Analysis for Your Lab

- What is the function of a vibratory sieve shaker? Achieve Precise Particle Size Analysis