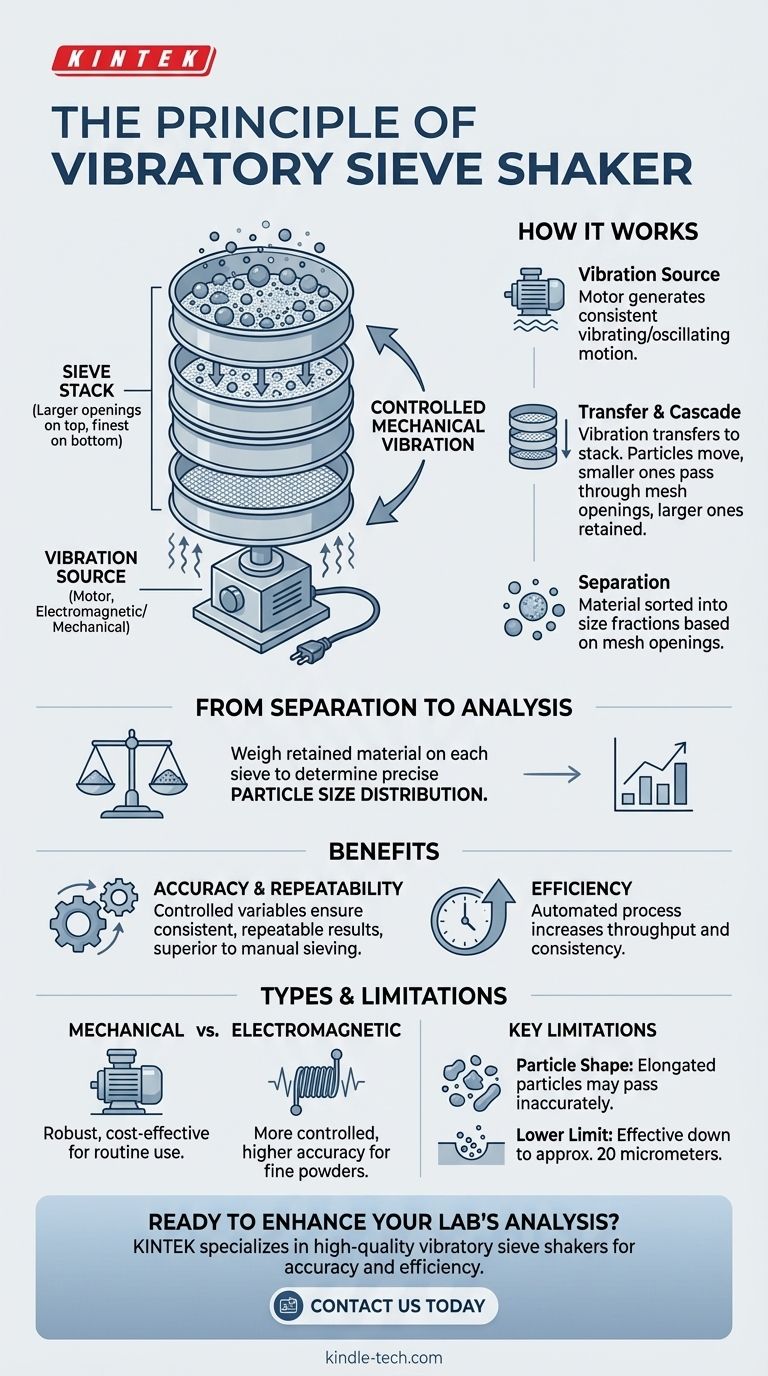

The fundamental principle of a vibratory sieve shaker is to use a controlled mechanical vibration to separate particles by size. A motor generates this vibration, transferring the motion to a stack of nested test sieves. As the material on the sieves is agitated, particles smaller than the mesh openings of a given sieve pass through to the one below it, while larger particles are retained.

A vibratory sieve shaker automates the process of particle separation. It replaces inconsistent, manual hand-sieving with a repeatable and highly efficient mechanical action, ensuring accurate determination of a material's particle size distribution.

How Mechanical Vibration Achieves Separation

A sieve shaker transforms electrical energy into a precisely controlled mechanical motion to sort a sample material. This process is far more consistent and reliable than manual methods.

The Vibration Source

At the heart of the system is a vibration motor. This motor, often an electromagnetic drive or a mechanical motor with an eccentric weight, is designed to produce a consistent vibrating or oscillating motion.

Transfer to the Sieve Stack

The motor's vibration is transferred to the shaker's base, which securely holds a stack of test sieves. These sieves are arranged vertically, with the sieve having the largest mesh openings at the top and the finest mesh at the bottom.

The Separation Cascade

When the shaker is activated, the entire sieve stack vibrates. This agitation causes the sample material placed on the top sieve to move and spread out. Particles smaller than the top sieve's mesh fall through to the next level, where the process repeats.

This cascading effect continues down the stack, effectively sorting the sample into different size fractions, with each sieve retaining particles larger than its openings.

The Goal: From Separation to Analysis

The ultimate purpose of a sieve shaker is not just to sort materials, but to provide quantitative data for particle size analysis.

Quantifying the Distribution

After the shaking cycle is complete, the stack is disassembled. The amount of material retained on each individual sieve is carefully weighed.

This weight data allows you to calculate the percentage of the total sample that falls within each size range. The result is a precise particle size distribution for the material.

Ensuring Accuracy and Repeatability

The key advantage of a shaker over manual sieving is repeatability. By controlling variables like vibration amplitude and sieving time, the machine ensures that every test is performed under the same conditions. This consistency is critical for reliable quality control and research.

Understanding the Trade-offs

While powerful, vibratory sieve shakers are not a universal solution. Understanding their variations and limitations is key to proper application.

Mechanical vs. Electromagnetic Shakers

Standard mechanical shakers are workhorses, suitable for a wide range of materials and particle sizes. They are robust and cost-effective.

Electromagnetic shakers are powered by electromagnetic pulses. They often provide a more controlled, three-dimensional tapping motion, which is recommended for tests requiring higher accuracy, especially with very fine powders that might otherwise agglomerate.

The Impact of Particle Shape

The principle assumes roughly spherical particles. Elongated or flaky particles may pass through mesh openings end-on or clog the sieve, leading to inaccurate results. This is a fundamental limitation of the sieving method itself.

The Lower Limit of Sieving

Sieving is only effective down to a certain particle size, typically around 20 micrometers. For analyzing smaller, sub-micron particles, other methods like laser diffraction or dynamic light scattering are required.

Making the Right Choice for Your Goal

To apply this principle effectively, match the technology to your specific analytical need.

- If your primary focus is routine quality control: A standard mechanical sieve shaker provides the efficiency, consistency, and accuracy needed for most industrial applications.

- If your primary focus is high-precision research or fine powder analysis: An electromagnetic sieve shaker offers superior control and accuracy for more demanding characterizations.

- If your primary focus is increasing efficiency over manual methods: Any automated sieve shaker will provide a dramatic improvement in throughput, accuracy, and operator ergonomics.

Understanding this principle empowers you to move beyond simple sorting and toward truly accurate and repeatable particle analysis.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Uses controlled mechanical vibration to separate particles by size through a stack of test sieves. |

| Vibration Source | Motor (electromagnetic or mechanical with eccentric weight) generates consistent motion. |

| Separation Process | Particles smaller than a sieve's mesh pass through; larger particles are retained. |

| Primary Goal | Provides quantitative data for precise particle size distribution analysis. |

| Key Advantage | Ensures repeatability and accuracy, superior to manual sieving methods. |

| Typical Lower Limit | Effective for particles down to approximately 20 micrometers. |

Ready to enhance your lab's particle analysis with reliable and repeatable results? KINTEK specializes in high-quality lab equipment, including a range of vibratory sieve shakers designed for accuracy and efficiency. Whether you need a robust mechanical shaker for routine quality control or a precise electromagnetic model for advanced research, we have the solution for your laboratory needs. Contact us today to find the perfect sieve shaker for your application!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the function of a vibratory sieve shaker? Achieve Precise Particle Size Analysis

- What is the use of vibratory sieve shaker? Achieve Precise Particle Size Analysis for Your Lab

- What is the amplitude of a sieve shaker? A Guide to Optimizing Particle Separation

- What is the frequency of a vibrating screen? Unlock Optimal Material Separation Efficiency

- What are the precautions of sieve shaker? Ensure Accurate Particle Analysis & Protect Your Equipment