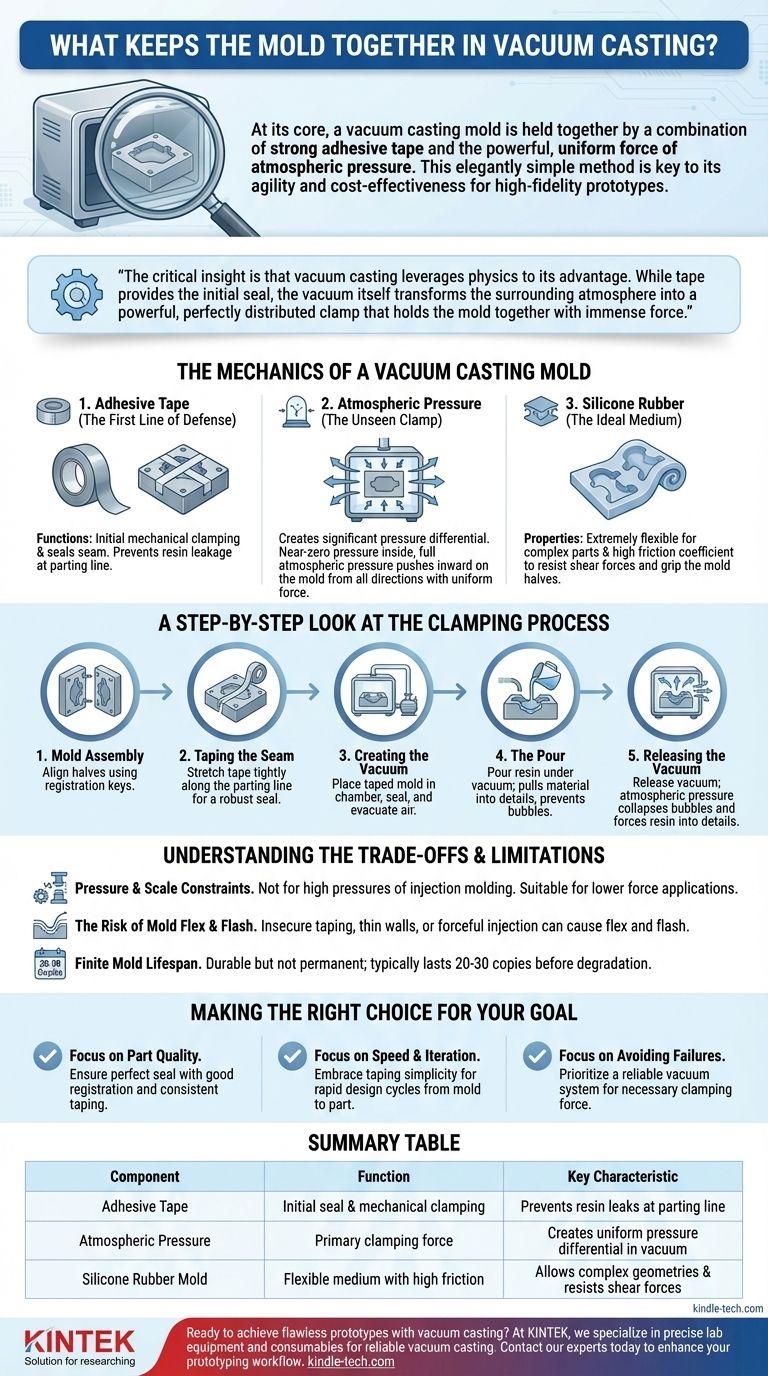

At its core, a vacuum casting mold is held together by a combination of strong adhesive tape and the powerful, uniform force of atmospheric pressure. This elegantly simple method is a key reason why the process is so agile and cost-effective for creating high-fidelity prototypes and low-volume production parts.

The critical insight is that vacuum casting leverages physics to its advantage. While tape provides the initial seal, the vacuum itself transforms the surrounding atmosphere into a powerful, perfectly distributed clamp that holds the mold together with immense force.

The Mechanics of a Vacuum Casting Mold

To understand why this simple system is so effective, you must look at how the different components work in concert. It's a system where each part plays a distinct and critical role.

The First Line of Defense: Adhesive Tape

The most direct and visible component holding the mold together is high-strength adhesive tape, often common duct tape.

After the two halves of the silicone mold are aligned, tape is wrapped securely around the entire parting line. This serves two primary functions: providing an initial mechanical clamping force and sealing the seam to prevent the liquid resin from leaking out.

The Unseen Clamp: Atmospheric Pressure

The true clamping power comes from the vacuum. When the taped mold is placed inside the chamber and the air is evacuated, a significant pressure differential is created.

The inside of the chamber is near-zero pressure (a vacuum), while the air trapped inside the sealed mold remains at atmospheric pressure. The result is that the full force of the atmosphere outside the mold (but inside the chamber) pushes inward on the mold from all directions, clamping it shut with incredible, uniform force.

The Ideal Medium: Silicone Rubber

The choice of silicone rubber for the mold is not accidental. Its properties are perfectly suited for this clamping method.

Silicone is extremely flexible, which allows for the casting of complex parts with undercuts that would be impossible with a rigid mold. Critically, it also has a high coefficient of friction, meaning the two halves of the mold grip each other and resist the shear forces of the injected resin.

A Step-by-Step Look at the Clamping Process

The security of the mold is established through a clear, repeatable sequence of events. Each step builds on the last to ensure a perfect seal and a high-quality final part.

1. Mold Assembly

The two halves of the cured silicone mold are carefully aligned. This alignment is guaranteed by registration keys—interlocking bumps and indentations that were designed into the mold master and are perfectly replicated in the silicone.

2. Taping the Seam

With the halves aligned, tape is stretched tightly along the entire parting line. The goal is to create a complete and robust seal, leaving no gaps where the liquid urethane could escape.

3. Creating the Vacuum

The taped mold, along with funnels for pouring, is placed in the bottom portion of the vacuum chamber. The chamber is sealed, and a vacuum pump removes nearly all the air.

4. The Pour

While the chamber is held under vacuum, the two-part urethane resin is mixed and poured into the mold. The vacuum not only pulls the material into the finest details of the cavity but also ensures there are no trapped air bubbles.

5. Releasing the Vacuum

Once the mold is full, the vacuum is released. Air rushes back into the chamber, and the return of atmospheric pressure helps to collapse any microscopic bubbles and force the resin into every last detail of the mold cavity.

Understanding the Trade-offs and Limitations

This method, while effective, is specifically tailored for the low-pressure environment of vacuum casting. Understanding its limitations is key to using it successfully.

Pressure and Scale Constraints

The tape-and-vacuum clamping method is not designed for the extreme pressures of processes like injection molding, which require hardened steel molds held in massive hydraulic presses. The forces in vacuum casting are orders of magnitude lower, making a simple silicone mold viable.

The Risk of Mold Flex and Flash

If a mold is not taped securely, has walls that are too thin, or if the resin is injected too forcefully, the mold can flex. This can cause a thin layer of material, known as flash, to escape at the parting line, which must be manually removed later.

Finite Mold Lifespan

Silicone molds are durable but not permanent. The repeated stress of demolding, handling, and the chemical interaction with casting resins limits a mold's lifespan, typically to 20-30 copies. After this, the fine details begin to degrade, and the mold may become prone to tearing.

Making the Right Choice for Your Goal

The simplicity of the vacuum casting mold system is its greatest strength, but it requires a correct understanding of the principles at play to achieve reliable results.

- If your primary focus is part quality: Ensure your mold has well-designed registration keys and that you use a firm, consistent taping technique to create a perfect seal.

- If your primary focus is speed and iteration: Embrace the simplicity of the taping process, as it allows you to move from a finished mold to a cast part in minutes, accelerating your design cycle.

- If your primary focus is avoiding failures: Pay close attention to your vacuum system, as the pressure differential provides the majority of the clamping force needed to prevent mold flex and resin leaks.

By understanding that simple tape and the invisible force of the atmosphere work together, you can confidently produce exceptional parts using this powerful manufacturing process.

Summary Table:

| Component | Function | Key Characteristic |

|---|---|---|

| Adhesive Tape | Initial seal and mechanical clamping | Prevents resin leaks at the parting line |

| Atmospheric Pressure | Primary clamping force | Creates uniform pressure differential in vacuum |

| Silicone Rubber Mold | Flexible medium with high friction | Allows for complex geometries and resists shear forces |

Ready to achieve flawless prototypes with vacuum casting?

At KINTEK, we specialize in providing the precise lab equipment and consumables needed for reliable vacuum casting processes. Whether you're iterating on designs or producing low-volume parts, our expertise ensures your molds are sealed perfectly every time.

Contact our experts today to discuss how our solutions can enhance your prototyping workflow and deliver superior part quality.

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Ball Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Cylindrical Press Mold for Lab Applications

- Special Heat Press Mold for Lab Use

People Also Ask

- What are the advantages of using PEEK molds for sulfide all-solid-state batteries? High Performance and Insulation

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity

- What role do high-temperature pressure molds play in SiCp/Al fabrication? Enhancing Densification and Thermal Uniformity

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?